Steeping liquor used as a means of controlling the risk of fire and explosion of organic extractive materials

a technology of organic extractive materials and steeping liquor, which is applied in the field of concentrated steeping liquor, can solve the problems of potential fire sources, explosion of a hybrid of gas and dust, and explosion of a hybrid of gas and dust, and achieve the effect of durable avoiding the binding of moistur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

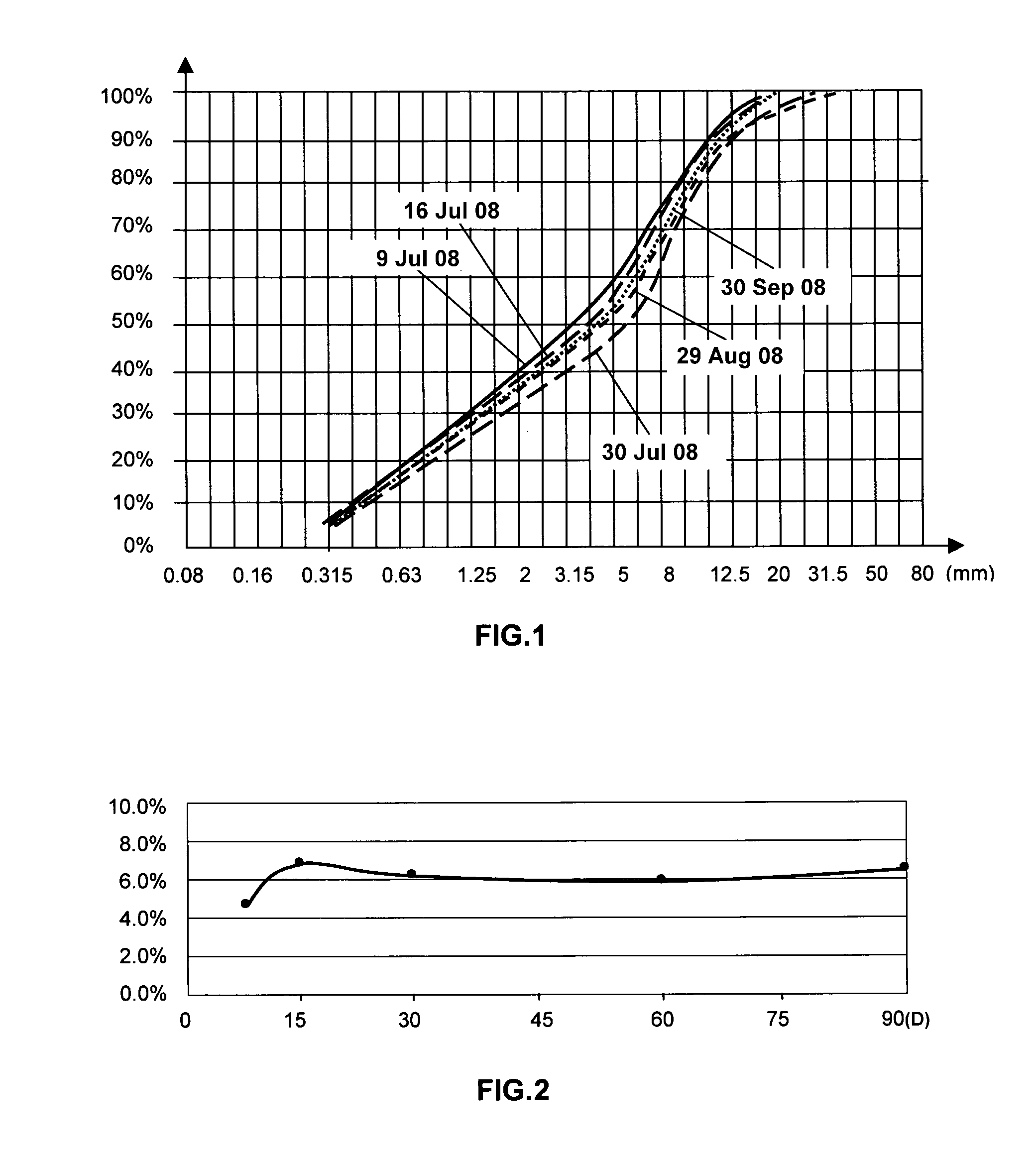

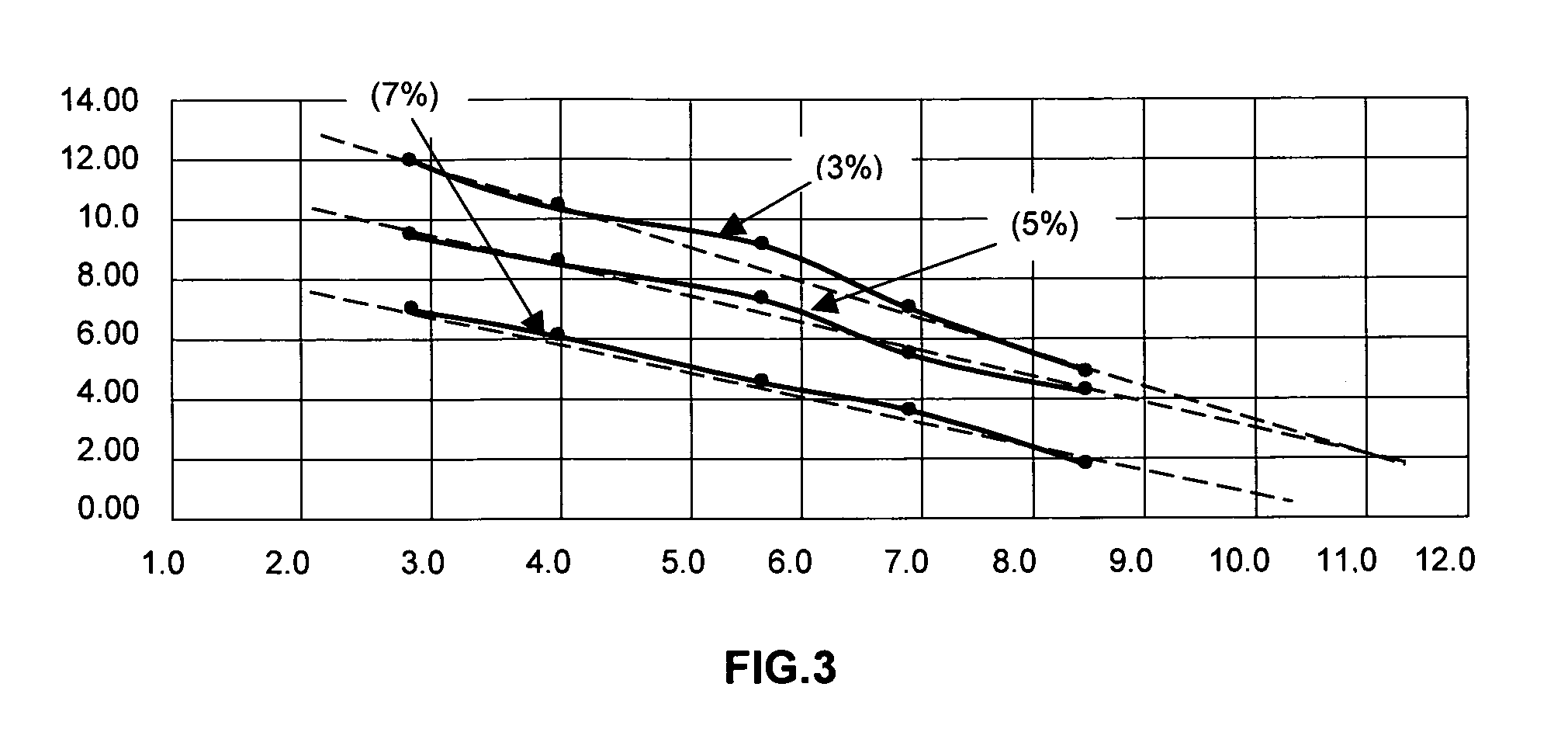

[0099]The tests comprised:[0100]a monitoring of progression of particle size, water content and apparent density of a control stock of treated materials situated on the right-of-way of the bulk terminal of the Port of South of France at Sète, over the period July-September 2008, by CEBTP / SOLEN of Montpellier, then by the inventor from October 2008 to July 2009 regarding the monitoring of temperatures, in order to ensure representative external conditions (the control stock representing a mass of approximately 50 t);[0101]an optimization study enabling specification of the progression of the percentage of smalls and the apparent density by varying the percentage of the composition tested in a mixture diluted with water, then by varying the percentage of this mixture, referred to as dosage, relative to the quantity of treated material.

[0102]The progression monitoring focused more particularly on:[0103]the water content;[0104]the density;[0105]the particle size.

[0106]The table below sum

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap