Strontium chloride expansive disks and compression welded cartridge and method

a technology of expansive disks and ammonia, which is applied in the direction of machines/engines, packaged goods types, separation processes, etc., can solve the problems of high concentrations of nosub>x /sub>, the risk of transporting ammonia as a pressurized liquid, and the inability to dose aqueous urea solution at a low engine load, etc., to achieve the effect of additional structural and operating advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail a preferred embodiment of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to embodiments illustrated.

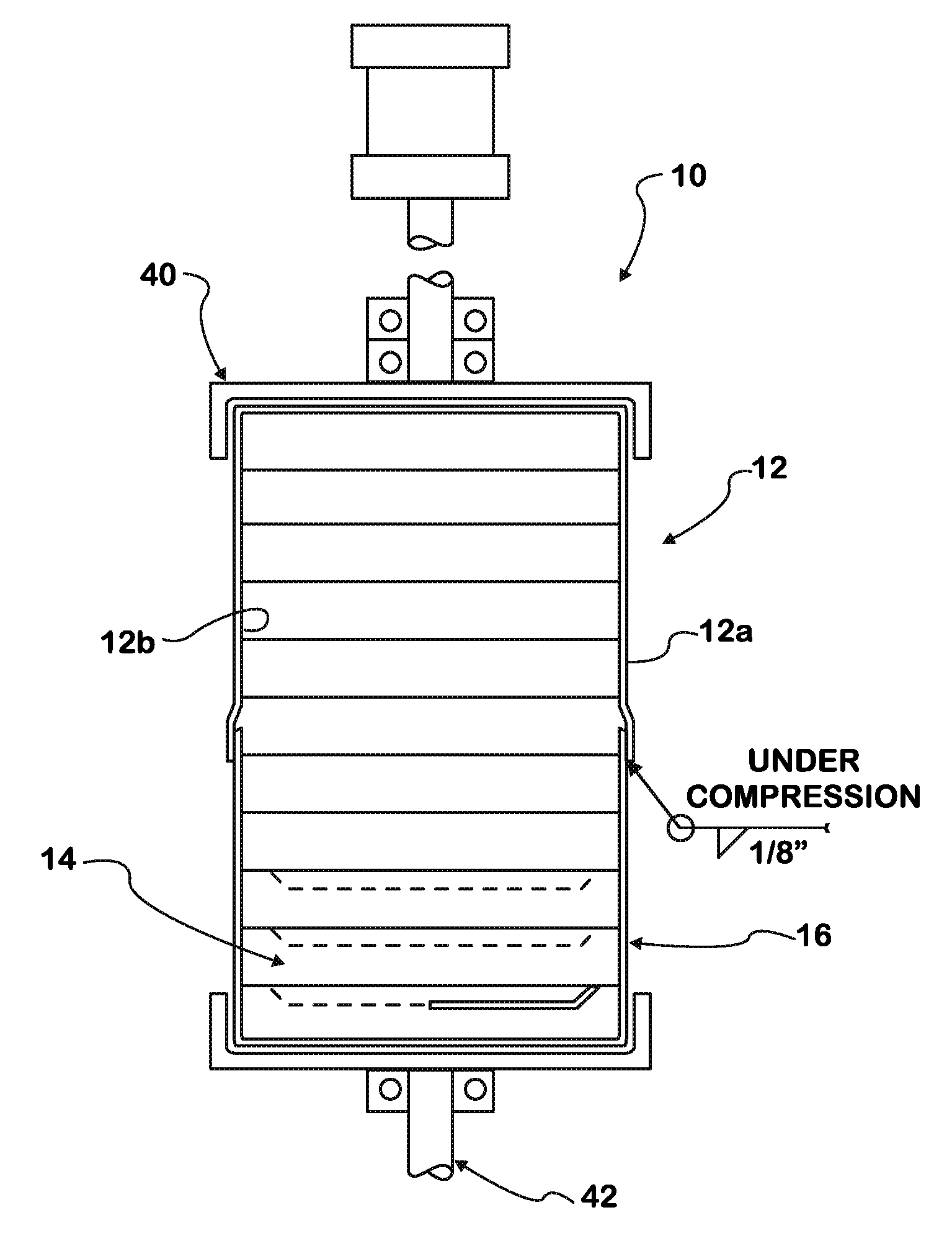

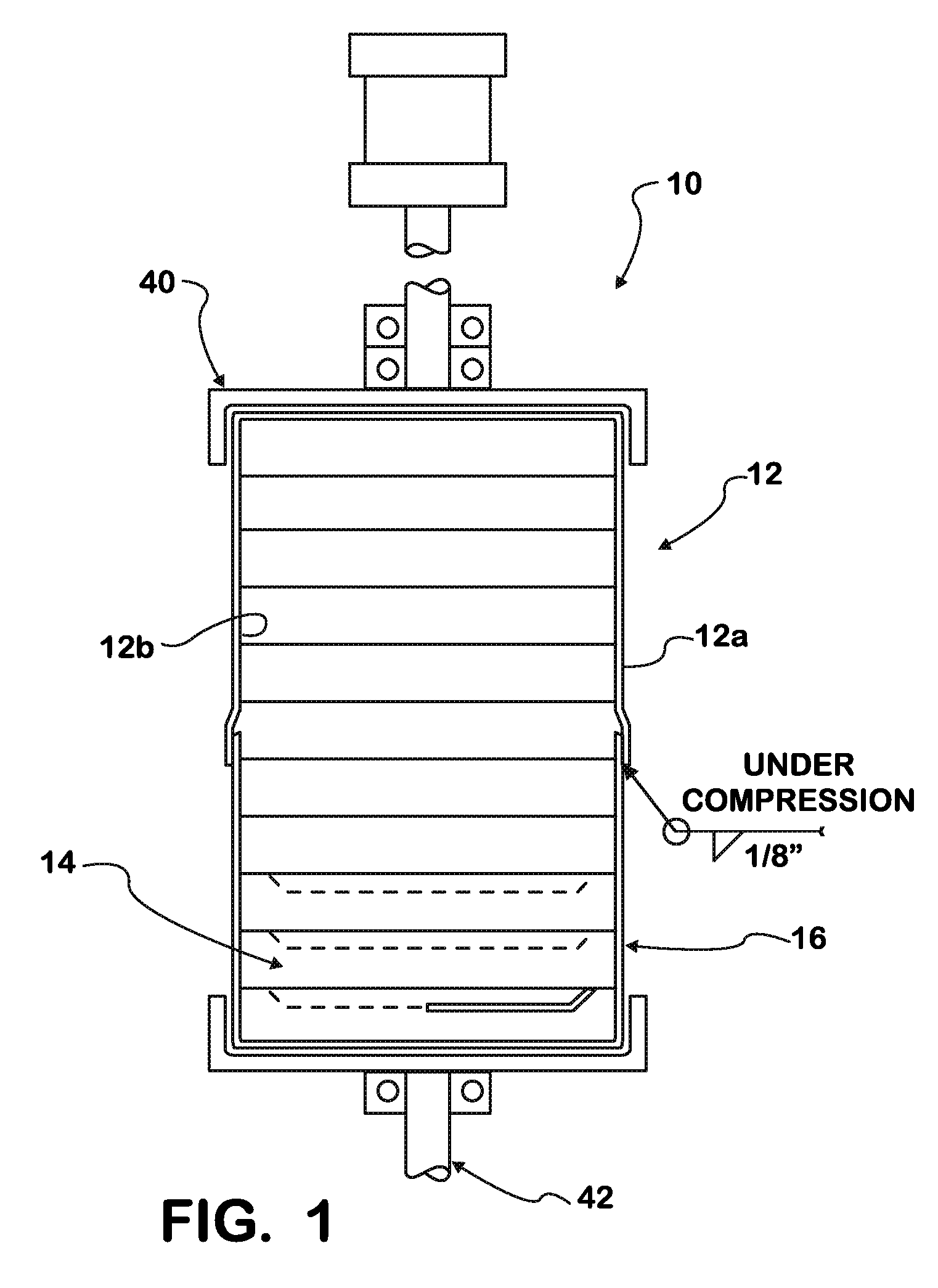

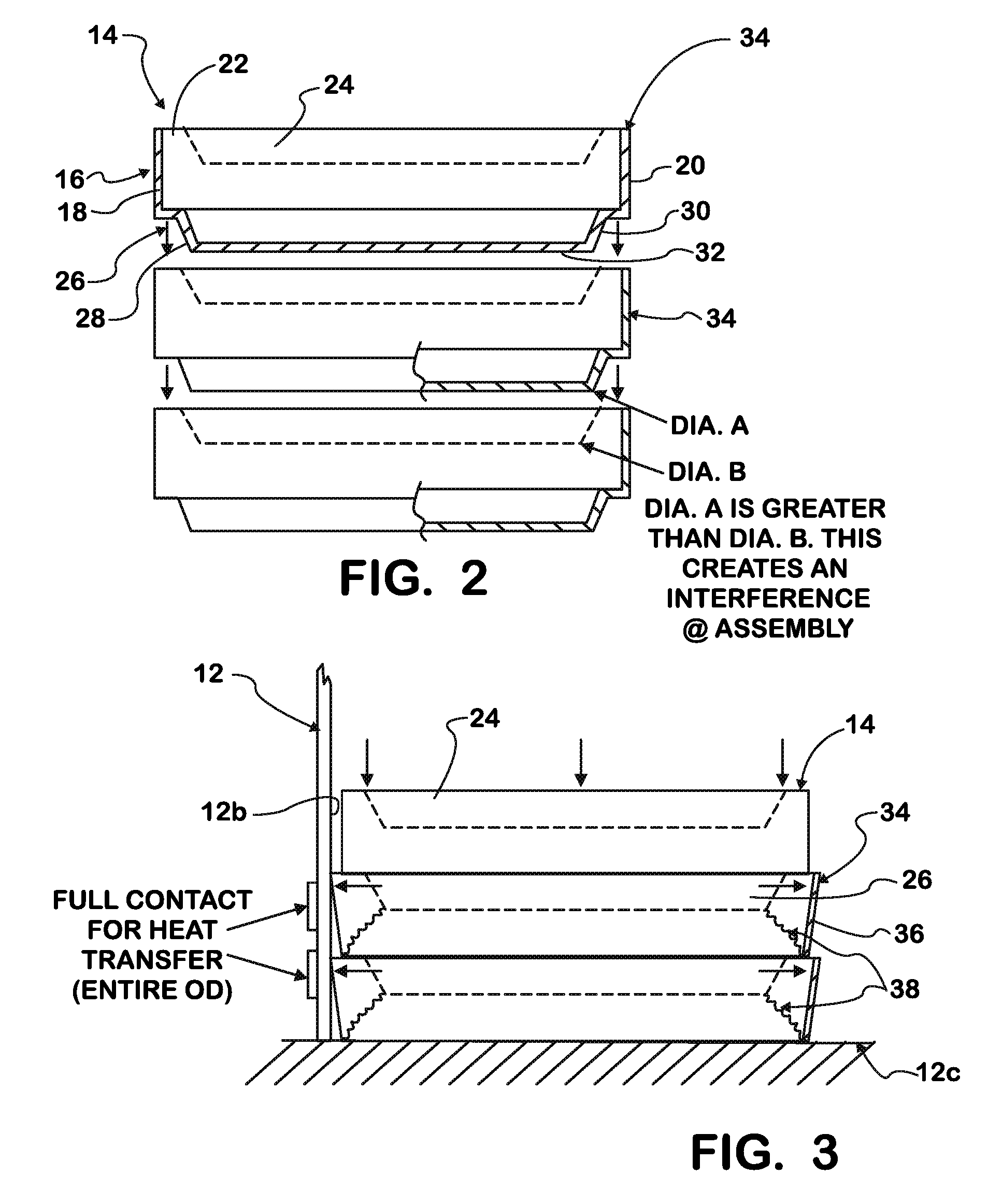

[0019]Referring to FIGS. 1-3, there is illustrated an assembly and method for storage and delivery of ammonia, specifically in a solid form, for use on a vehicle (not shown). The assembly of the present invention, generally designated by the numeral 10, is discussed with respect to ammonia storage and delivery, and specifically to supplying ammonia gas to a combustion engine. Ammonia gas is useful in the exhaust system (not shown) of a vehicle for the reduction of NOx. As the exhaust system of a vehicle, including that of a diesel engine, is well known, it will not be described in de

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap