Formulations and Dosage Forms of Oxidized Phospholipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Encapsulation of VB-201 in Gelatin Capsules Using a Lauroglycol FCC Carrier

[0438]The solubility of VB-201 in Lauroglycol FCC (propylene glycol laurate) was tested, and was found to be at least 255 mg per gram. VB-201 was also found to be stable in Lauroglycol FCC over the course of 66 days (data not shown). Based on these results, Lauroglycol FCC was considered to be a suitable liquid carrier for VB-201.

[0439]In order to test the stability of VB-201 in gelatin capsules, size 0 capsules were filled with 255 mg / gram VB-201 in Lauroglycol FCC and then sealed. Capsules were stored under the following storage conditions; a) ambient relative humidity at 4° C.; b) 65% relative humidity at room temperature; and c) 75% relative humidity at 40° C.

[0440]As shown in Table 1, VB-201 content in the capsules was reduced, in contrast to the results obtained for VB-201 in Lauroglycol FCC in the absence of capsules.

[0441]In order to determine whether the VB-201 interacted with the gelatin in a way whi

example 2

Hygroscopicity of VB-201

[0448]The physical properties of VB-201 were examined in order to understand the mechanism whereby VB-201 causes cracking of gelatin capsules, as described in Example 1.

[0449]The aqueous solubility of VB-201 was determined by suspending VB-201 in aqueous solutions of 0.1 M HCl (pH 1) or in 50 mM phosphate buffers (pH 5 and 7). After initial hand mixing, the preparations were further mixed by vortexing and bath sonication to try to bring about dissolution of the drug. Optical microscopy was used to examine for the presence of undissolved material. Using this method, it was determined that the solubility of VB-201 at each of the tested pH values is in excess of 225 mg / gram. Thus, VB-201 is relatively water-soluble.

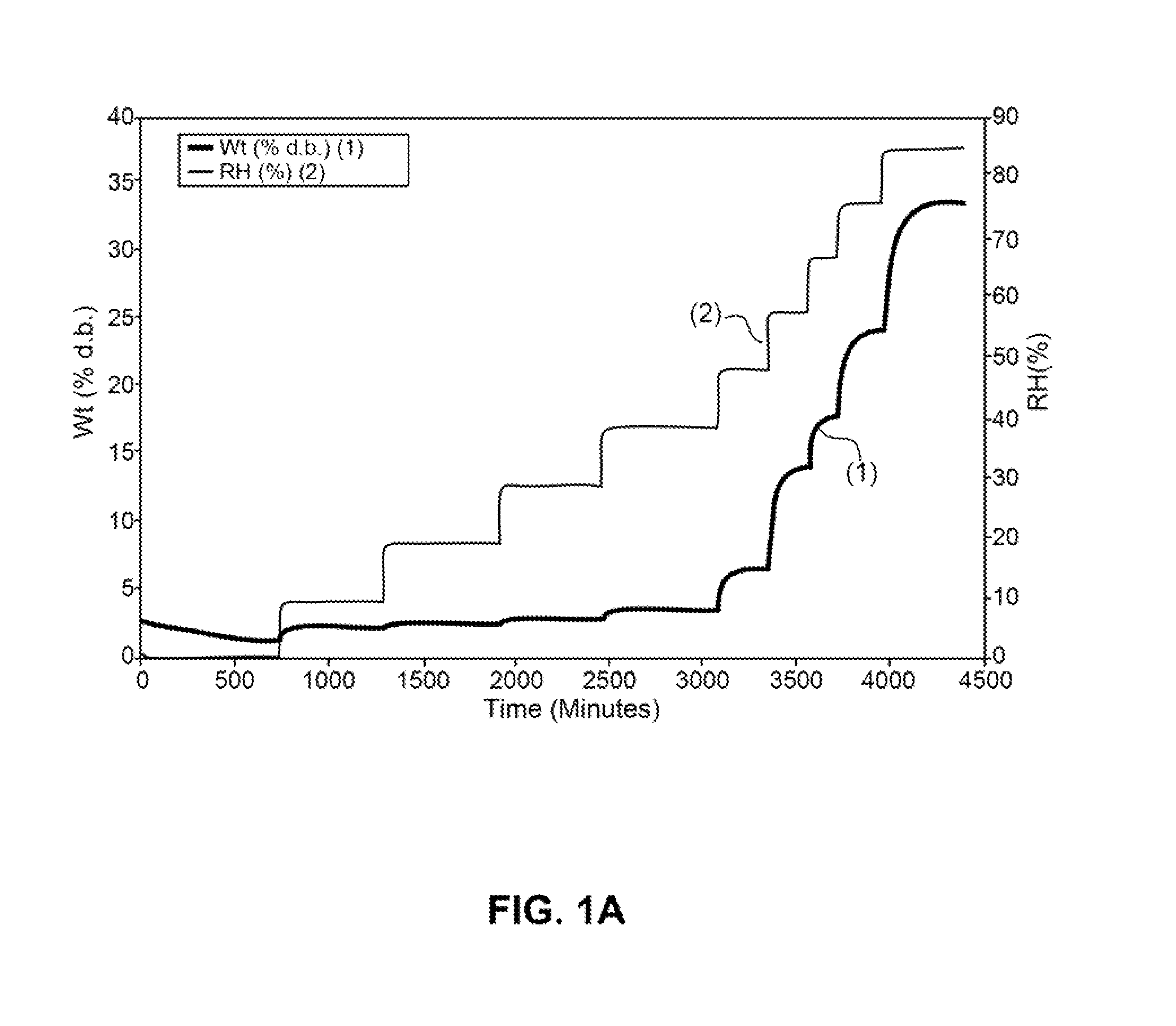

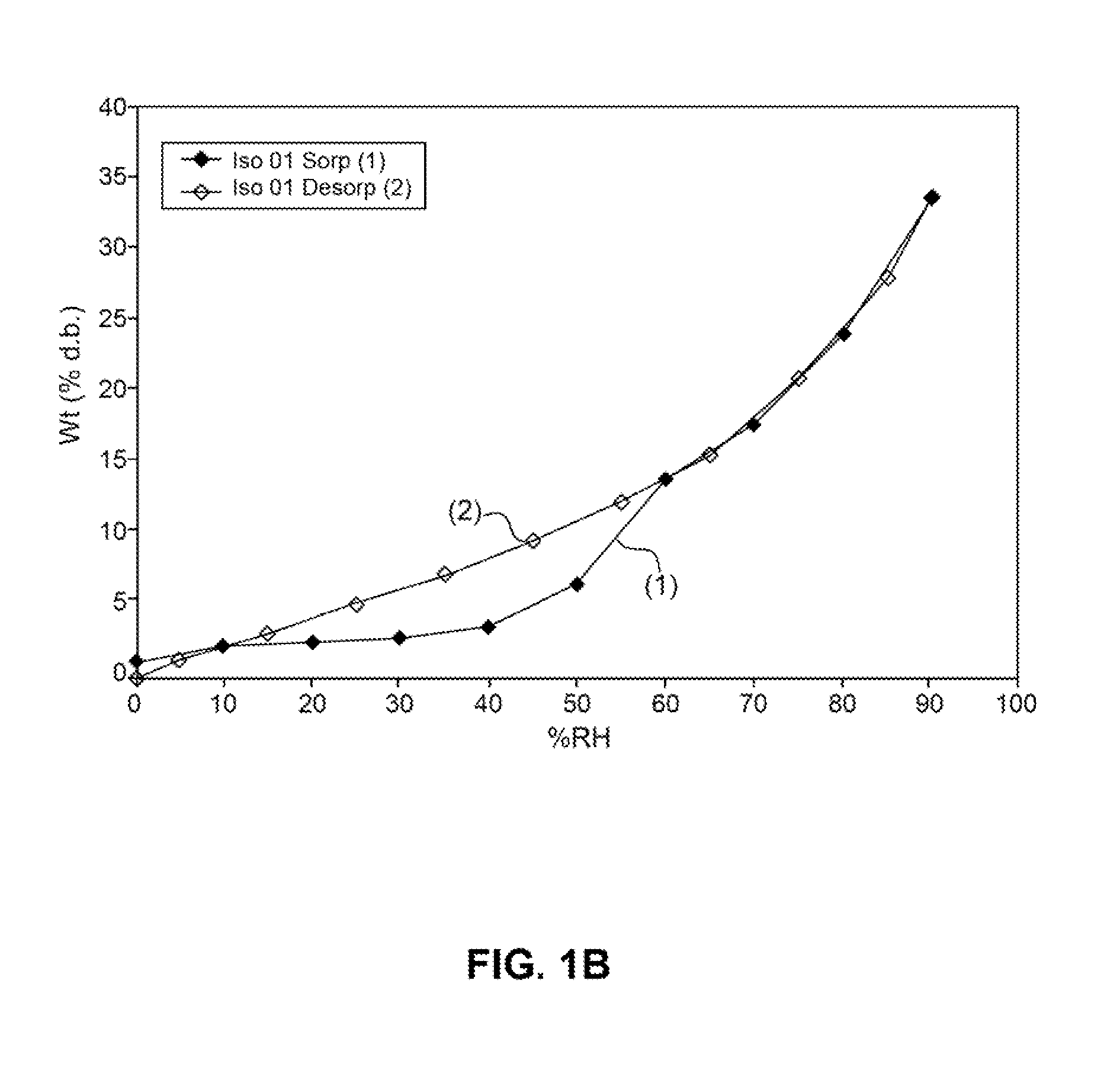

[0450]Absorption of humidity by VB-201 was determined by gravimetric vapor sorption analysis, as described in the Materials and Methods section.

[0451]As shown in FIGS. 1A and 1B, a slight weight loss was observed when VB-201 was exposed to 0% relative

example 3

Encapsulation of VB-201 in Gelatin Capsules Using a Solid Carrier

[0464]In order to provide a more stable gelatin capsule containing VB-201, VB-201 was incorporated into a solid excipient having a low melting point, by adding VB-201 to the molten excipient.

[0465]The solid formulation was expected to be advantageous because no leakage is possible, the VB-201 is immobilized and therefore prevented from interacting with the gelatin shell wall, and absorption of water by VB-201 would be limited.

[0466]In order to facilitate HPLC analysis, the excipient was selected to have little UV absorption and to be water-soluble. The excipient was further selected so as to be FDA-approved. Based on the aforementioned criteria, PEG6000 (polyethylene glycol with a molecular weight of 6000 daltons) and TPGS (tocopherol polyethylene glycol succinate) were selected as suitable excipients, and tested in order to determine which excipient provides the best stability. The melting point of TPGS is about 40° C.,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap