Vacuum pump connecting apparatus and method for installing vacuum pump connecting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

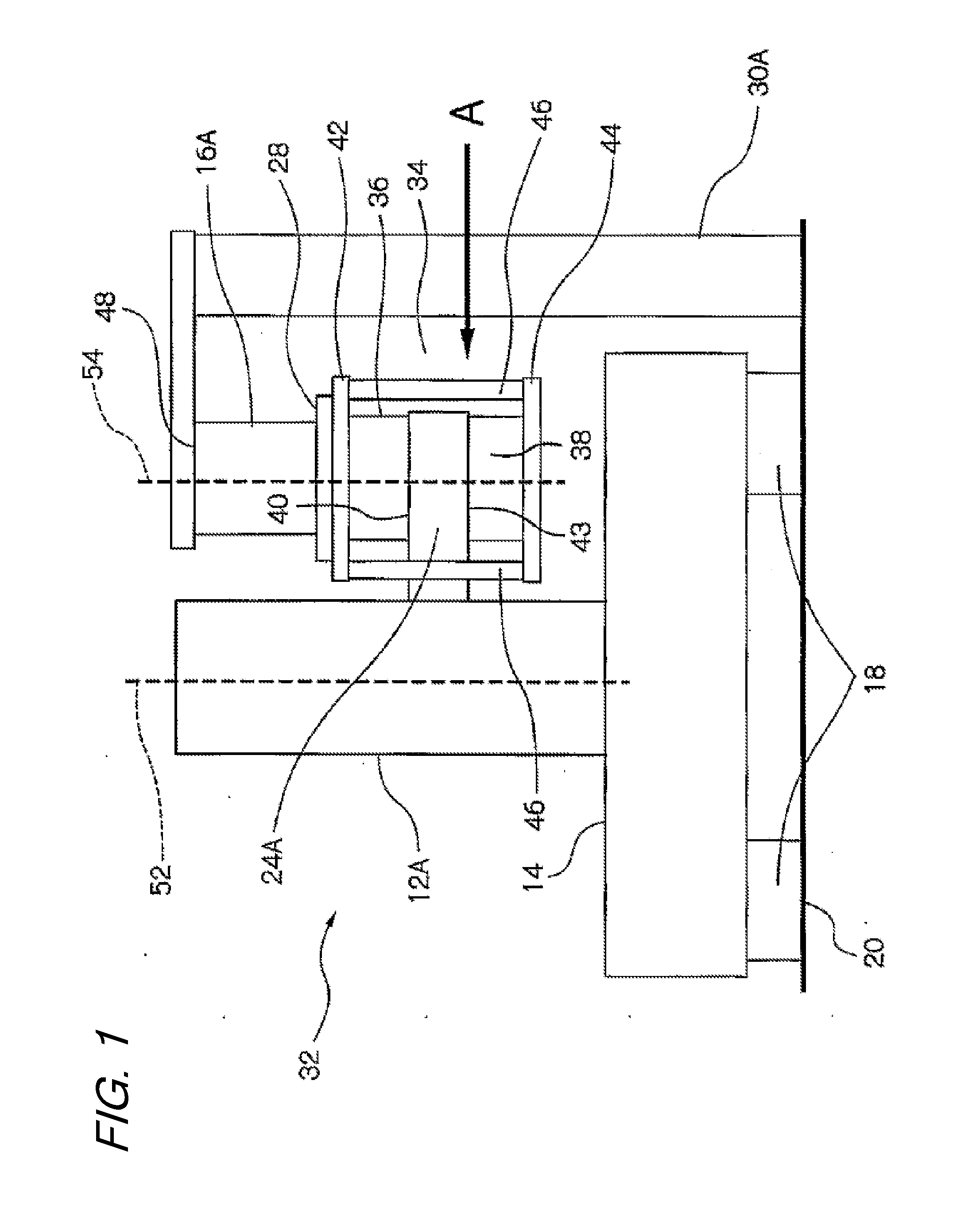

[0046]Embodiments of the present invention will be described below with reference to the drawings.

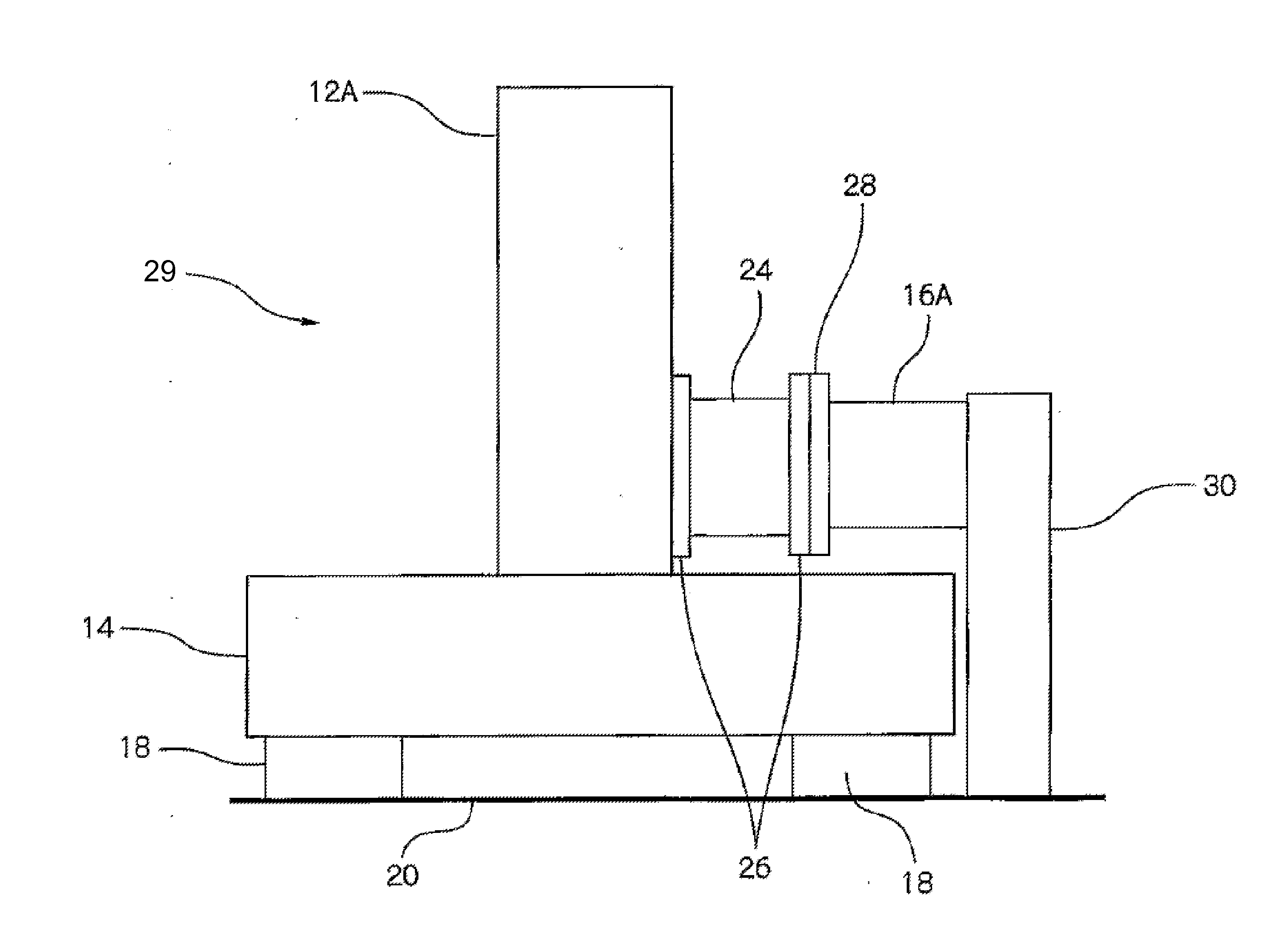

[0047]FIG. 1 is a front view of an electron beam application apparatus 32 and a vacuum pump connecting apparatus 34 showing an embodiment of the present invention. A vacuum pump 16A has an intake port 28 and an exhaust port. The vacuum pump 16A sucks, through the intake port 28, a gas in a lens barrel portion 12A of the electron beam application apparatus 32 which is to be evacuated, and discharges the gas through the exhaust port. The vacuum pump connecting apparatus 34 includes an evacuation connection portion 24A that connects the intake port 28 of the vacuum pump 16A to the lens barrel portion 12A.

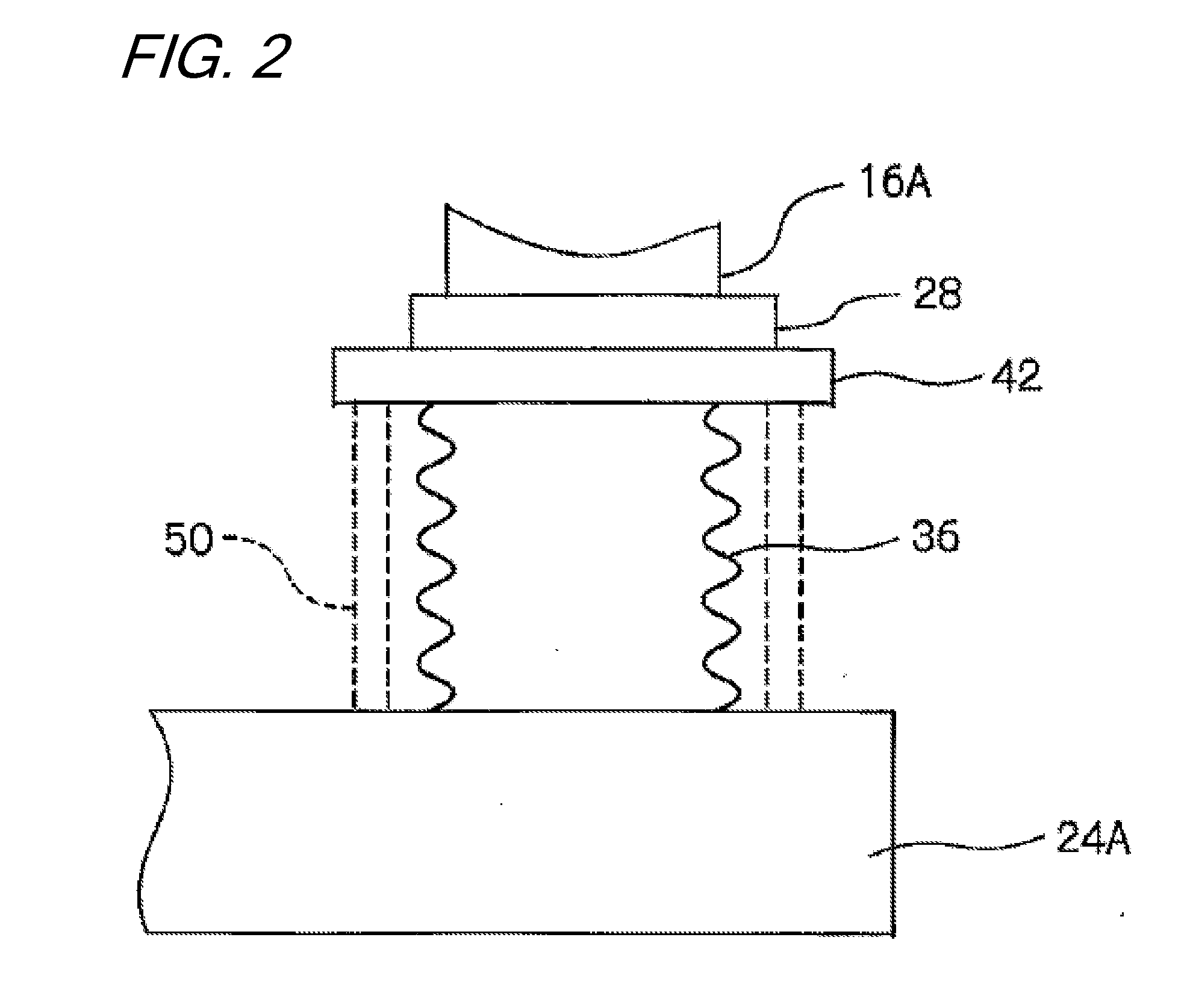

[0048]The vacuum pump connecting apparatus 34 has a first vibration absorbing portion 36 and a second vibration absorbing portion 38 which are connected to the evacuation connection portion 24A so that the first vibration absorbing portion 36 and the second vibration absorbing portion 38 lie

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap