Three-dimensional printing methods and materials for making dental products

a three-dimensional printing and dental technology, applied in the field of three-dimensional printing articles for making dental products, can solve the problems of high cost and high risk of dental implantation, inability to meet mass production easily, time-consuming and labor-intensive dental devices, etc., to achieve no toxic effect, good biological compatibility, and reduce the cost of dental materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

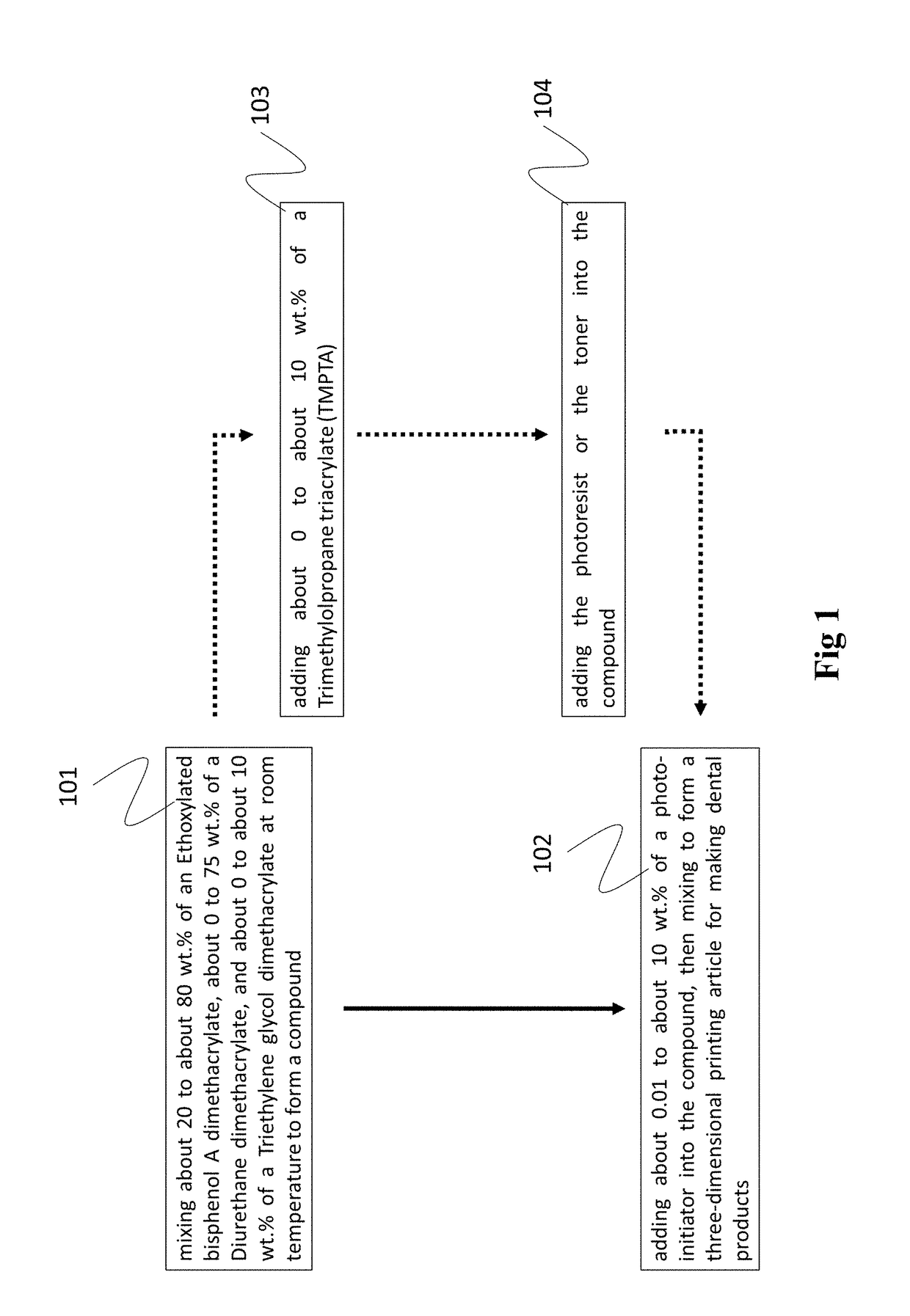

[0015]The present invention provides a three-dimensional printing article for making dental products, comprising: a compound made of about 20 to about 80 wt % of Ethoxylated bisphenol A dimethacrylate (BisEMA) (Formula I), preferably, said Ethoxylated bisphenol A dimethacrylate comprises ethoxyl chain with n=2, and m=2, 4 or 10;

about 0 to 75 wt % Diurethane dimethacrylate (UDMA) (Formula II);

about 0 to about 10 wt % Triethylene glycol dimethacrylate (TEGDMA) (Formula III); and

about 0.01 to about 10 wt % of a photo-initiator, preferably, the photo-initiator is Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO).

[0016]Preferably, said compound further composing: about 0 to about 10 wt % of Trimethylolpropane triacrylate (TMPTA) (Formula IV);

[0017]In one embodiment, the three-dimensional printing article for making dental products, comprising: a photoresist, wherein the photoresist is consisted of about 0.1 to about 10 wt % of silicon dioxide or silylated silicon dioxide, and about 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap