Catalyst system for oxidative dehydrogenation, reactor for oxidative dehydrogenation including catalyst system, and method of performing oxidative dehydrogenation using reactor

a catalyst system and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, hydrocarbon preparation catalysts, etc., can solve the problems of reducing reaction efficiency, reducing catalyst life, and method being unsatisfactory in terms of productivity and yield, so as to reduce catalyst deterioration, reduce catalyst deterioration, and reduce the effect of heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

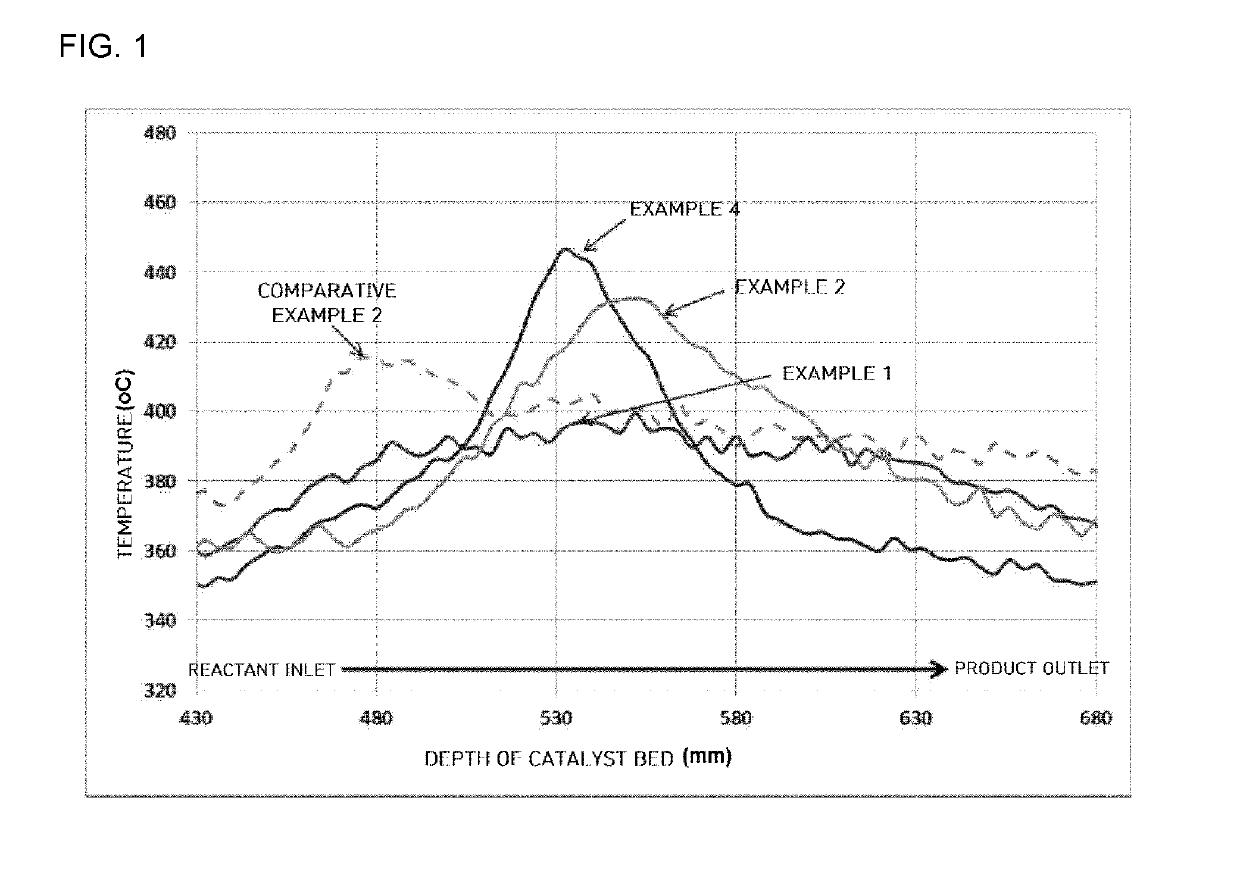

[0064]The catalyst composition was loaded into a reactor in an incremental manner in a three-stage structure as shown in Table 2 below. Then, reaction was performed under the same conditions and in the same manner as in Example 1, except that the reaction was performed at the temperature specified in Table 2 below.

TABLE 2GHSV / mole ratio of butene:oxygen:steam:nitrogen =120 / 1:1:5:4, 360° C.X [content ofY [content of porousZnFe2O4, wt %]support, wt %]First stage694Second stage991Third stage1486[0065]In Table 2, each of X and Y is based on 100% by weight of the total amount thereof.

example 3

[0066]Reaction was performed under the same conditions and in the same manner as in Example 2, except that the molar ratio of butene:oxygen:steam:nitrogen was 1:1.2:5:4.

example 4

[0067]The catalyst composition was loaded into a reactor in an incremental manner in a three-stage structure as shown in Table 3 below. Then, reaction was performed under the same conditions and in the same manner as in Example 1, except that a reaction temperature was 347° C.

TABLE 3GHSV / mole ratio of butene:oxygen:steam:nitrogen =120 / 1:1:5:4, 347° C.X [content ofY [content of porousZnFe2O4, wt %]support, wt %]First stage991Second stage1486Third stage2773[0068]In Table 3, each of X and Y is based on 100% by weight of the total amount thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap