Seat support mechanism

a seat and support mechanism technology, applied in the direction of seats, movable seats, chairs, etc., can solve the problems of increasing the cost of parts, increasing the difficulty of discharging parts in a limited space around the legs of seats, and increasing the change-over time, so as to reduce the cost, improve the operability, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]Hereinbelow, an embodiment representing the present invention will be explained with reference to the drawings.

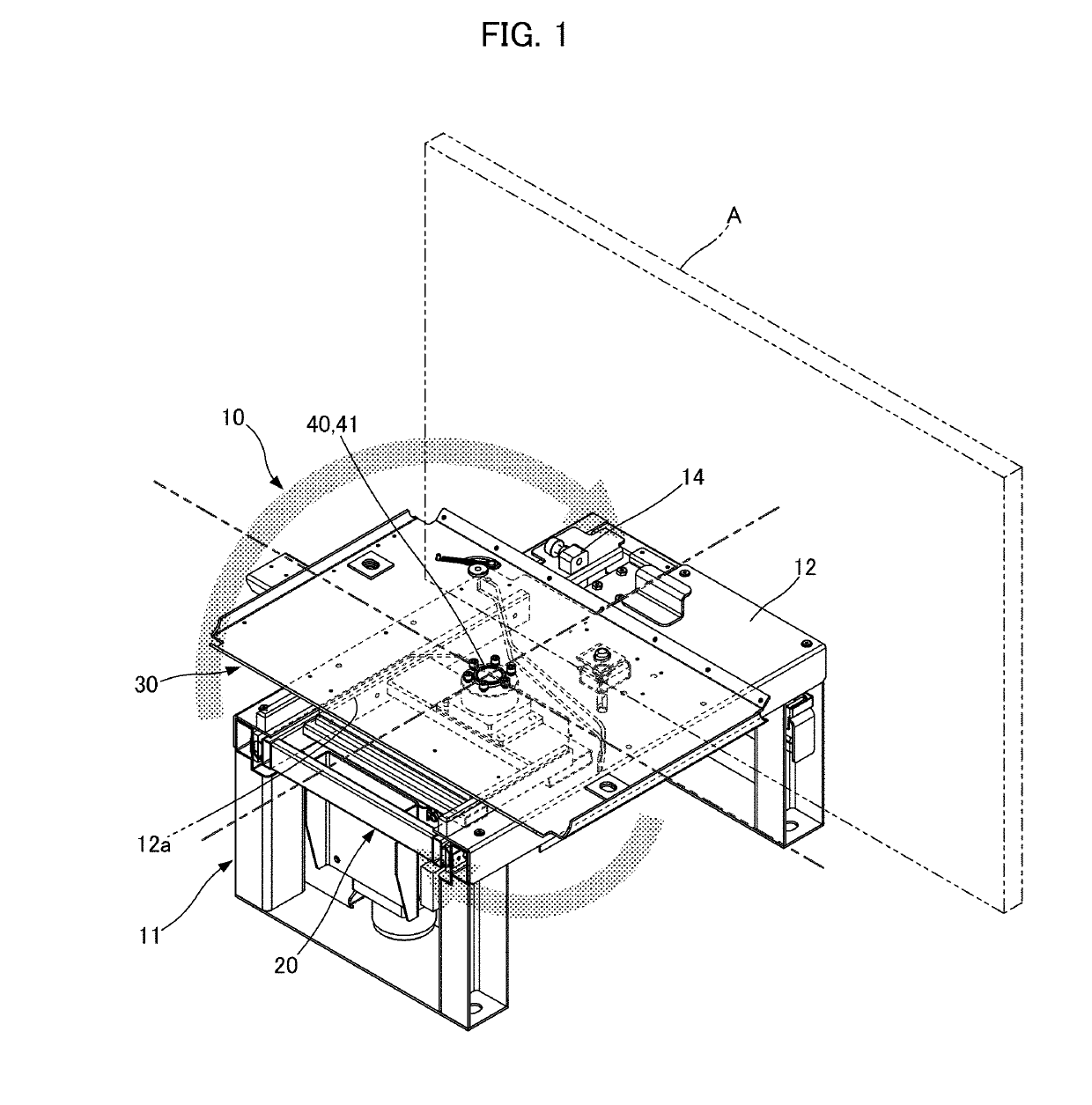

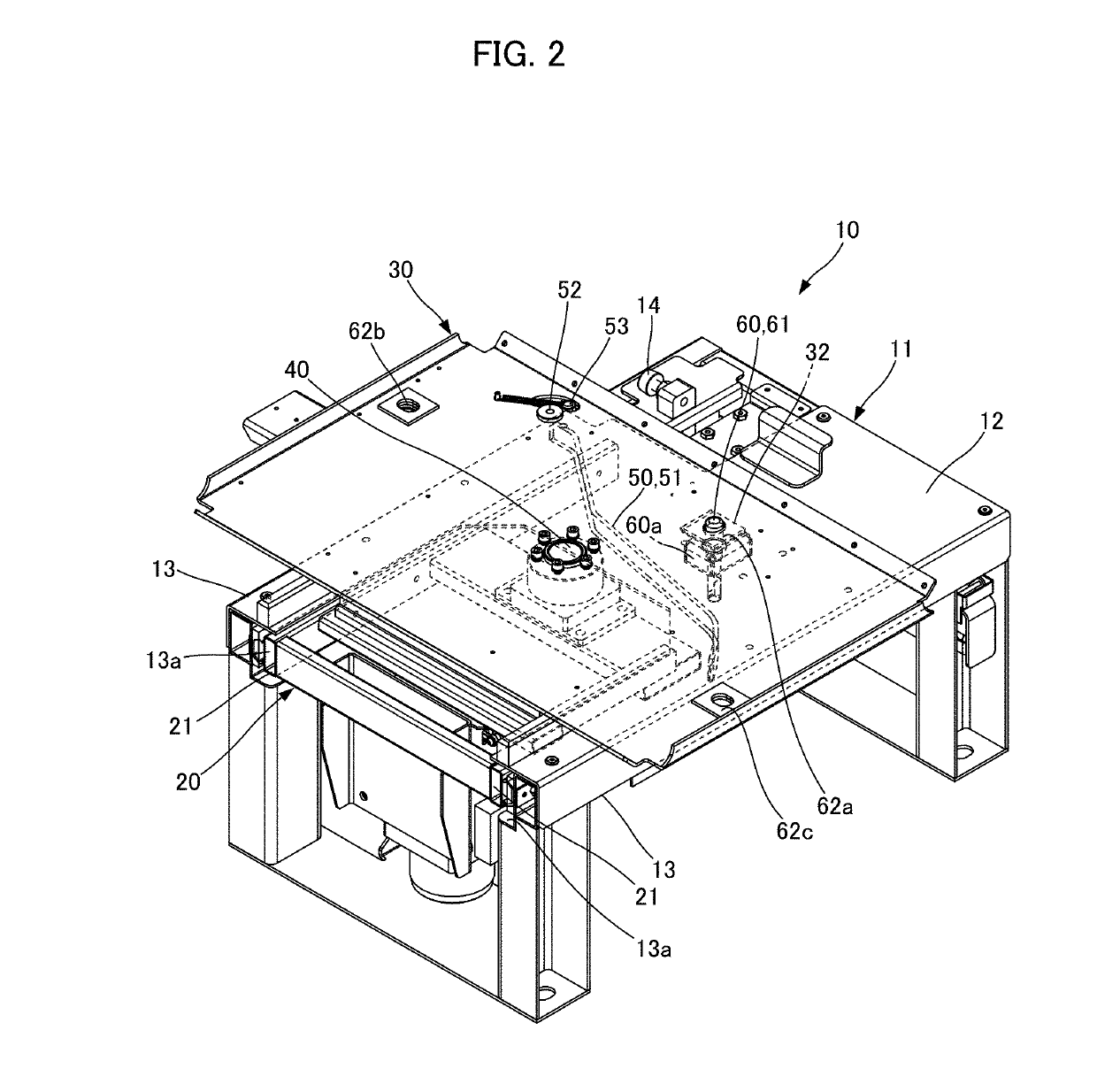

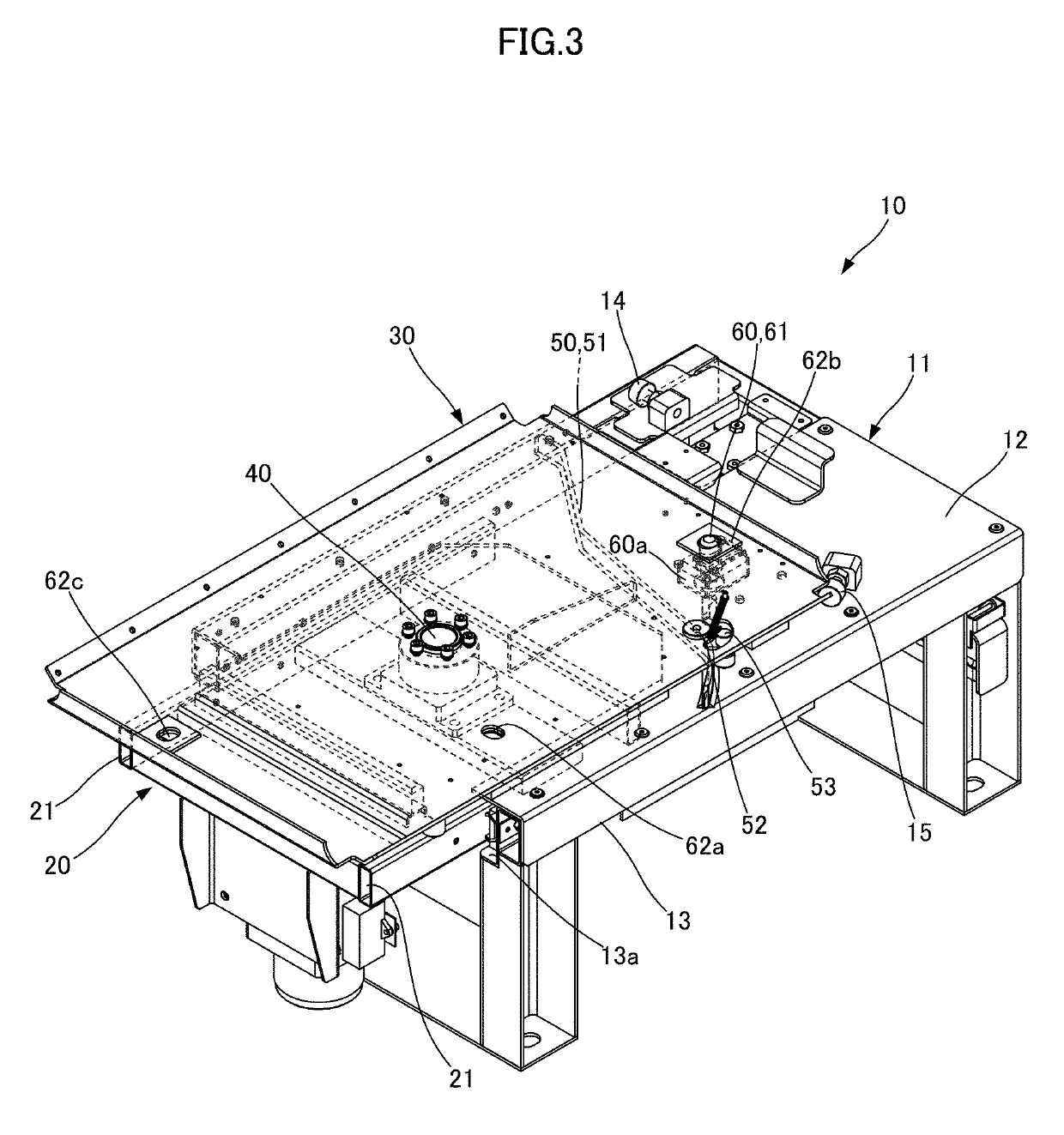

[0070]FIG. 1 to FIG. 26 show one embodiment of the present invention.

[0071]A seat support mechanism 10 according to an embodiment of the present invention is for turning a seat to change over the directed state thereof. Herein, the application for the seat is not particularly limited, however, hereinbelow, the case where the present invention is applied to a bench for two occupants that is to be equipped in a cabin of a railroad vehicle will be explained as an example. The symbol “A” in FIG. 1 denotes a part of a wall face in the vehicle cabin. Herein, the wall face refers to an internal wall face of a side wall provided in parallel with the direction of travel of the vehicle, and hereinbelow it will be referred to as the side wall A.

[0072]As shown in FIG. 1, the seat support mechanism 10 includes a leg pedestal 11, a moving pedestal 20, and an underframe 30 of the seat.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap