Dual purpose intermodal tank container

a technology of intermodal and tank containers, which is applied in the field of commodities carriers, can solve the problems of inability to meet the needs of transportation, etc., and achieve the effects of maximizing economic benefits, facilitating unrefined petroleum transportation, and maximizing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The tank container frame has standard intermodal ISO container dimensions. This way it can be transported in different modes without additional requirements. The design respects weight restrictions, primarily for road transportation, whose complete scope is known to those skilled in the art.

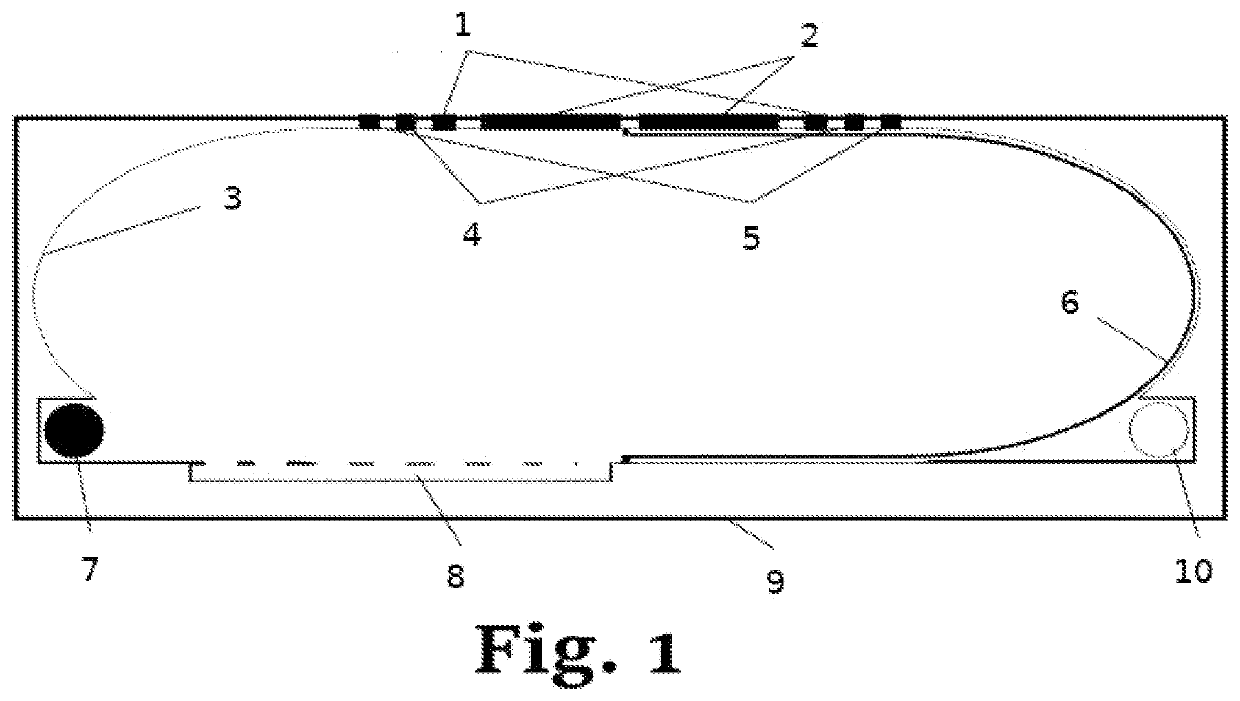

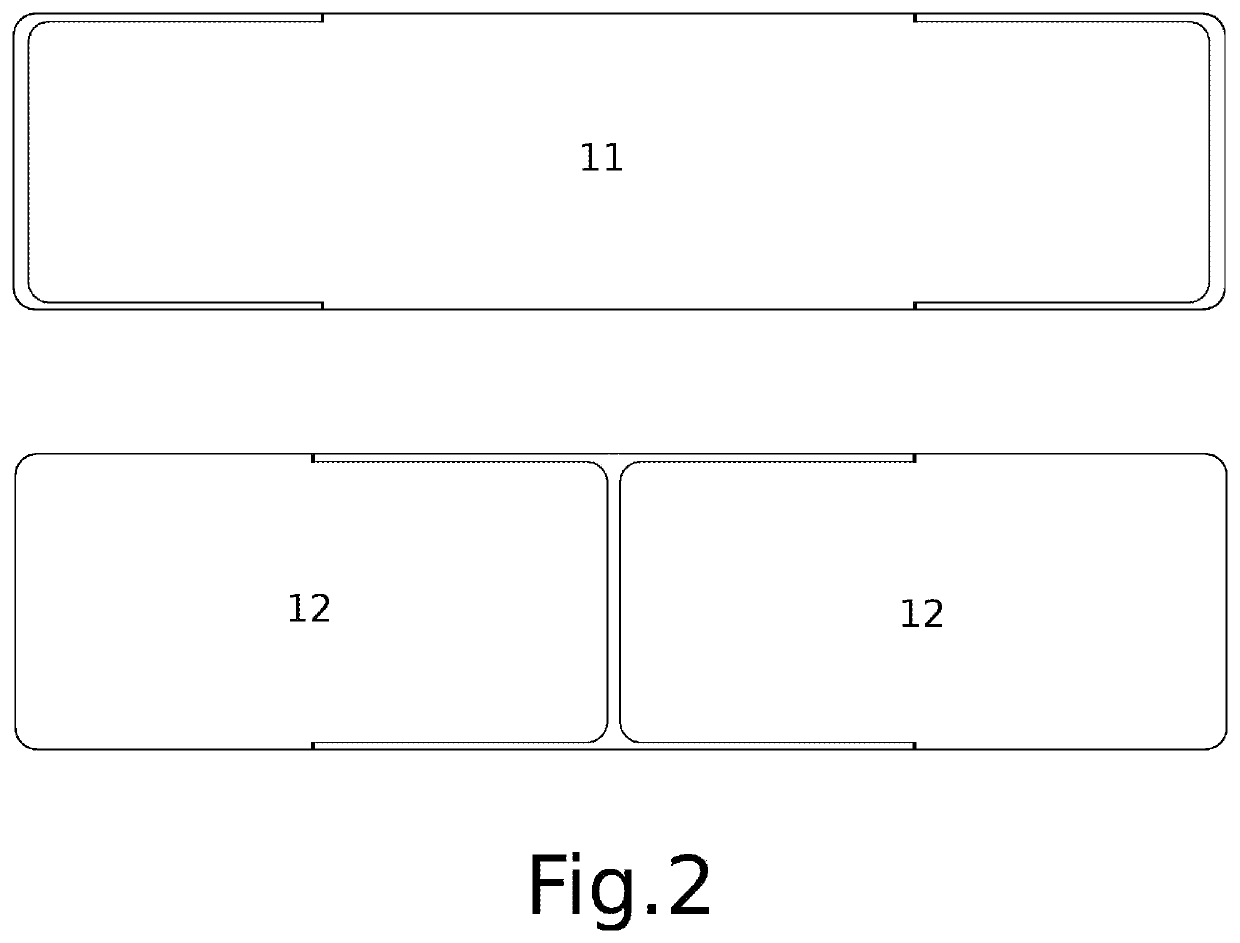

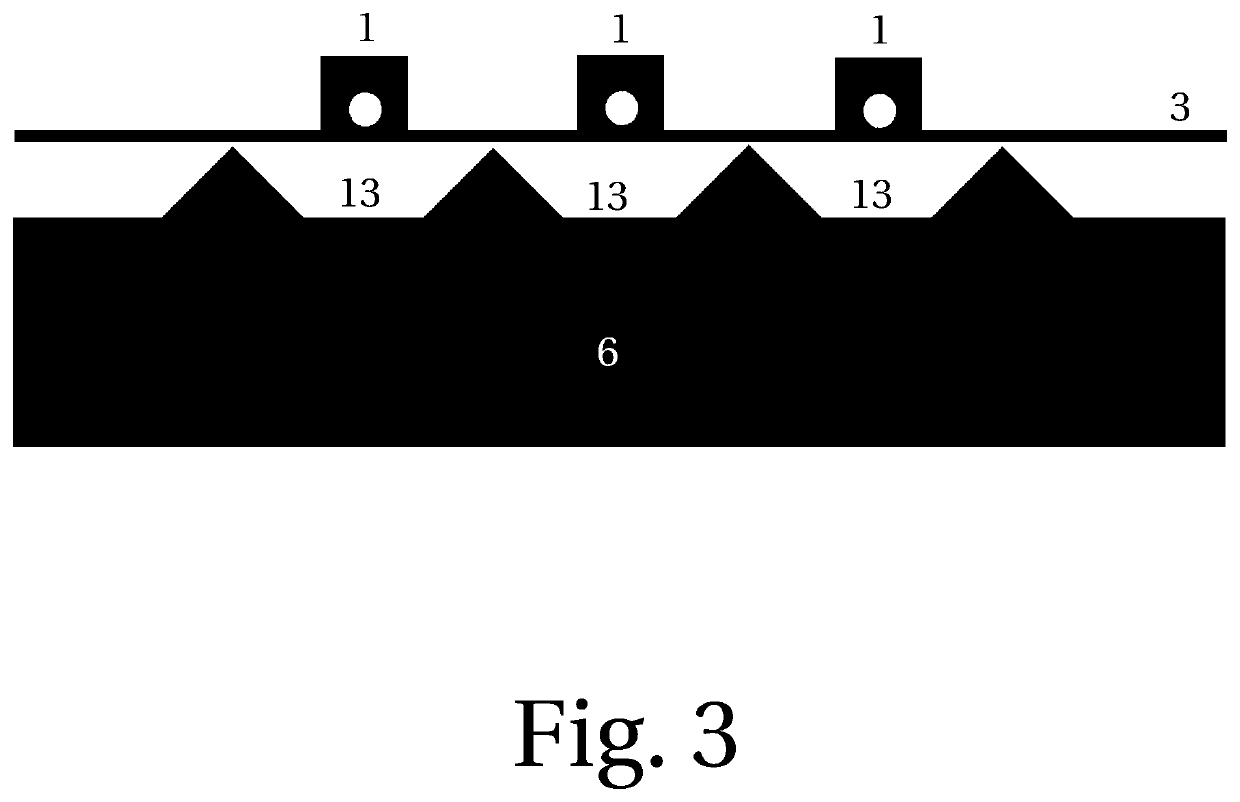

[0021]The tank diaphragm 6 intersects the tank girth wise in the middle in case of single diaphragm tank (FIG. 1) or anywhere else in case of multiple diaphragm tank (FIG. 2). In the two compartment tank in the FIG. 1, the diaphragm copies half of the tank shape and can turn inside out into the other side of the tank when pressured by gas or liquid. The tank halves are both designed for different use. The left compartment is for unrefined petroleum, the right compartment is for refined petroleum. Unrefined petroleum can be very viscous and sticky, for example, extra heavy oil hardly flows in ambient temperatures. Therefore, the left compartment could be optionally equipped with a heating mecha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap