Method for operating an automatically moving floor treatment appliance

a technology for floor treatment and automatic movement, applied in the direction of cleaning action control, carpet cleaners, instruments, etc., can solve the problems of subsequent floor treatment cycle, and achieve the effects of saving energy, time-saving and efficient, and prolonging the service life of the floor treatment applian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

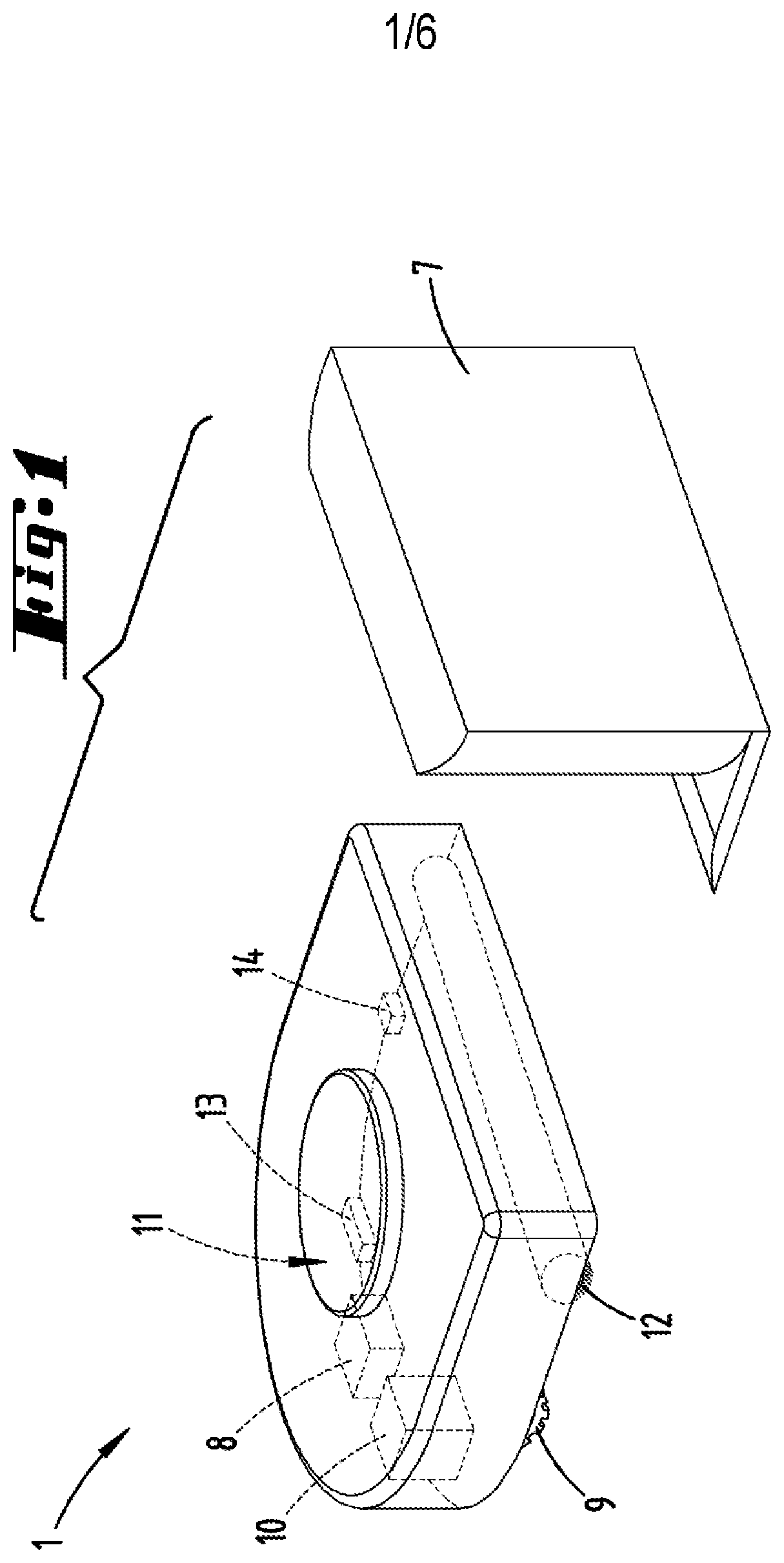

[0026]In an exemplary manner, FIG. 1 initially shows a floor treatment appliance 1 as well as a base station 7, which is configured to perform a service activity on the floor treatment appliance 1, for example to charge an accumulator (not illustrated) of the floor treatment appliance 1, to transfer tools to the latter, to clean the floor treatment appliance 1, or the like. The base station 7 furthermore represents an initial location for the floor treatment appliance 1, from which the floor treatment appliance 1 starts its movement routes.

[0027]The floor treatment appliance 1, which is illustrated in an exemplary manner, has a detection means 11, by means of which surrounding area data in the surrounding area of the floor treatment appliance 1 can be detected. The surrounding area data can be, for example, data of objects, which are located in the surrounding area, for example of walls, pieces or furniture, or the like. The detection means 11 can have, for example, an optical distance

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap