Electropneumatic control valve comprising a guide arrangement for a control piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

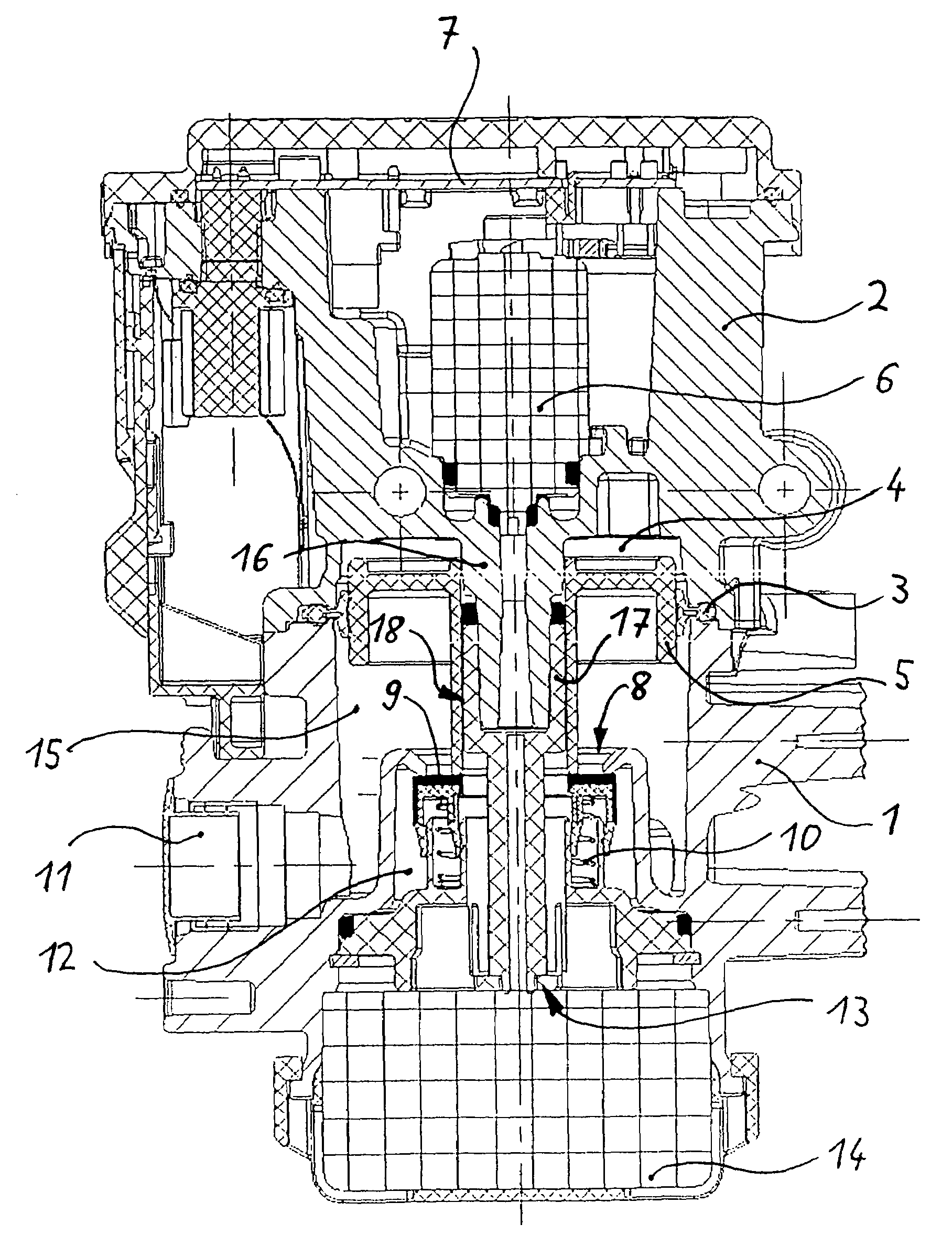

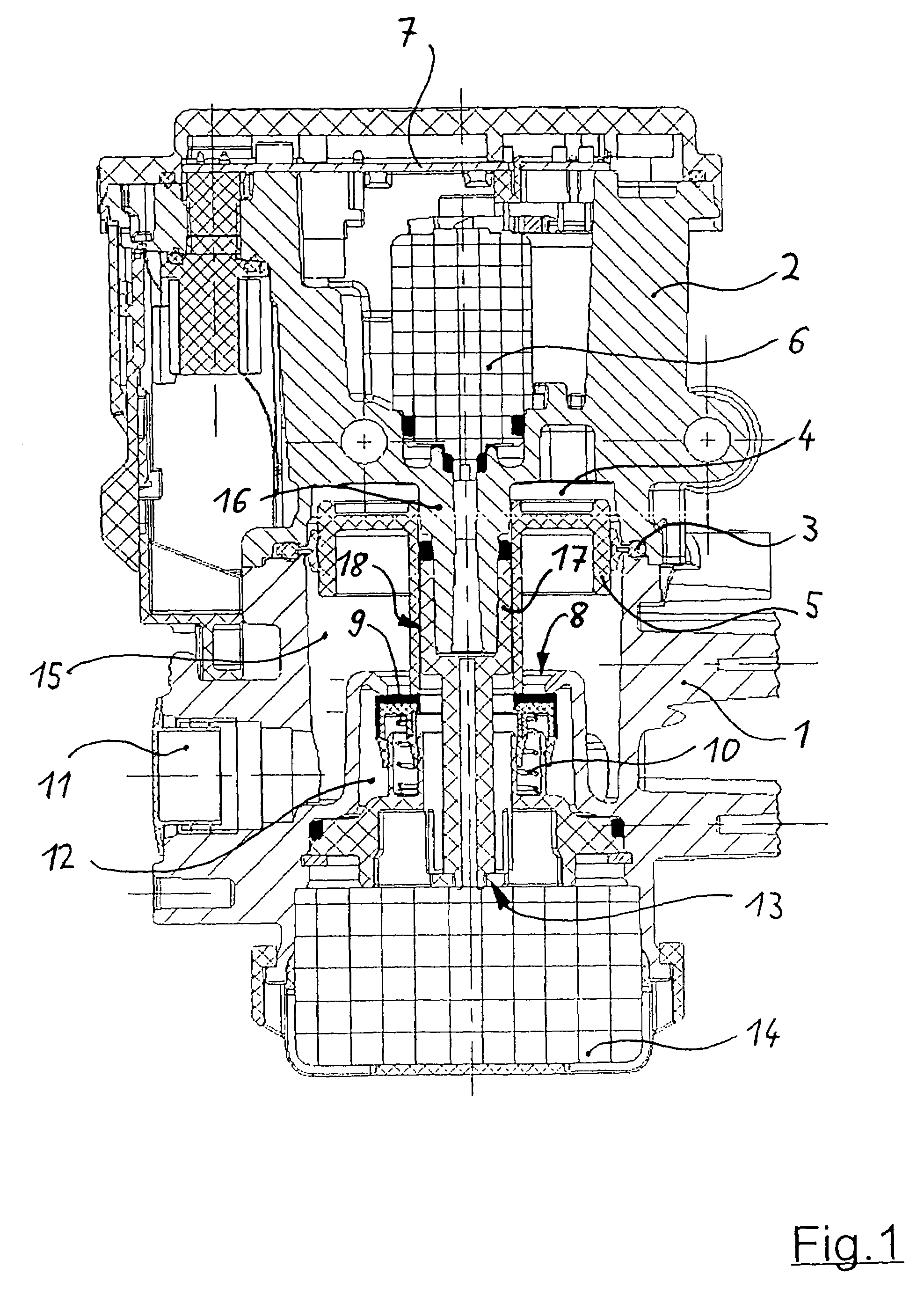

[0025]The electropneumatic control valve according to FIG. 1 has a housing arrangement which is essentially constructed in two parts and which consists of a lower relay valve housing 1 which is connected with an upper pilot valve housing 2, with sealing element 3 situated in-between. The connection takes place by means of a (not shown) screwed connection. The relay valve housing 1 and the pilot valve housing 2 enclose an interior control chamber 4 in which a control piston 5 is axially movably arranged. For the axial adjustment of the control piston 5, a pilot valve arrangement is used which is accommodated in the pilot valve housing 2 and of which only a pilot valve 6 is illustrated here. The pilot valve arrangement is electrically controlled here by means of an electronic unit. The illustrated pilot valve 6 is used as an outlet valve and, when operated, bleeds the control chamber 4, in which case the outgoing air is discharged to the atmosphere. In

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap