Waste treatment apparatus with integral membrane apparatus

a technology of wastewater treatment and membrane, applied in the direction of multi-stage water/sewage treatment, liquid displacement, separation process, etc., can solve the problems no aeration or biological treatment of membranes, and a large amount of bacteria, so as to achieve the effect of low electrical power consumption, minimal control, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

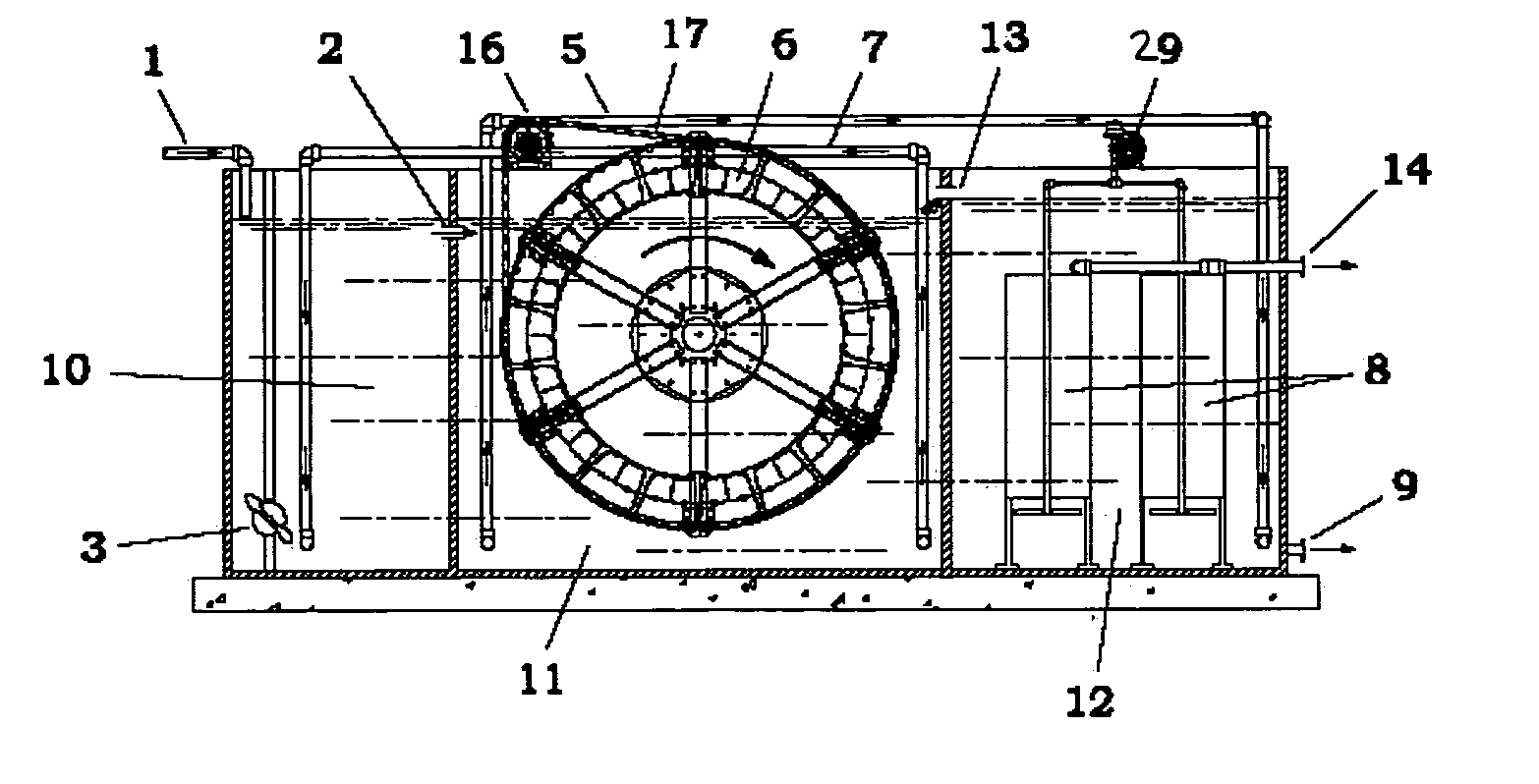

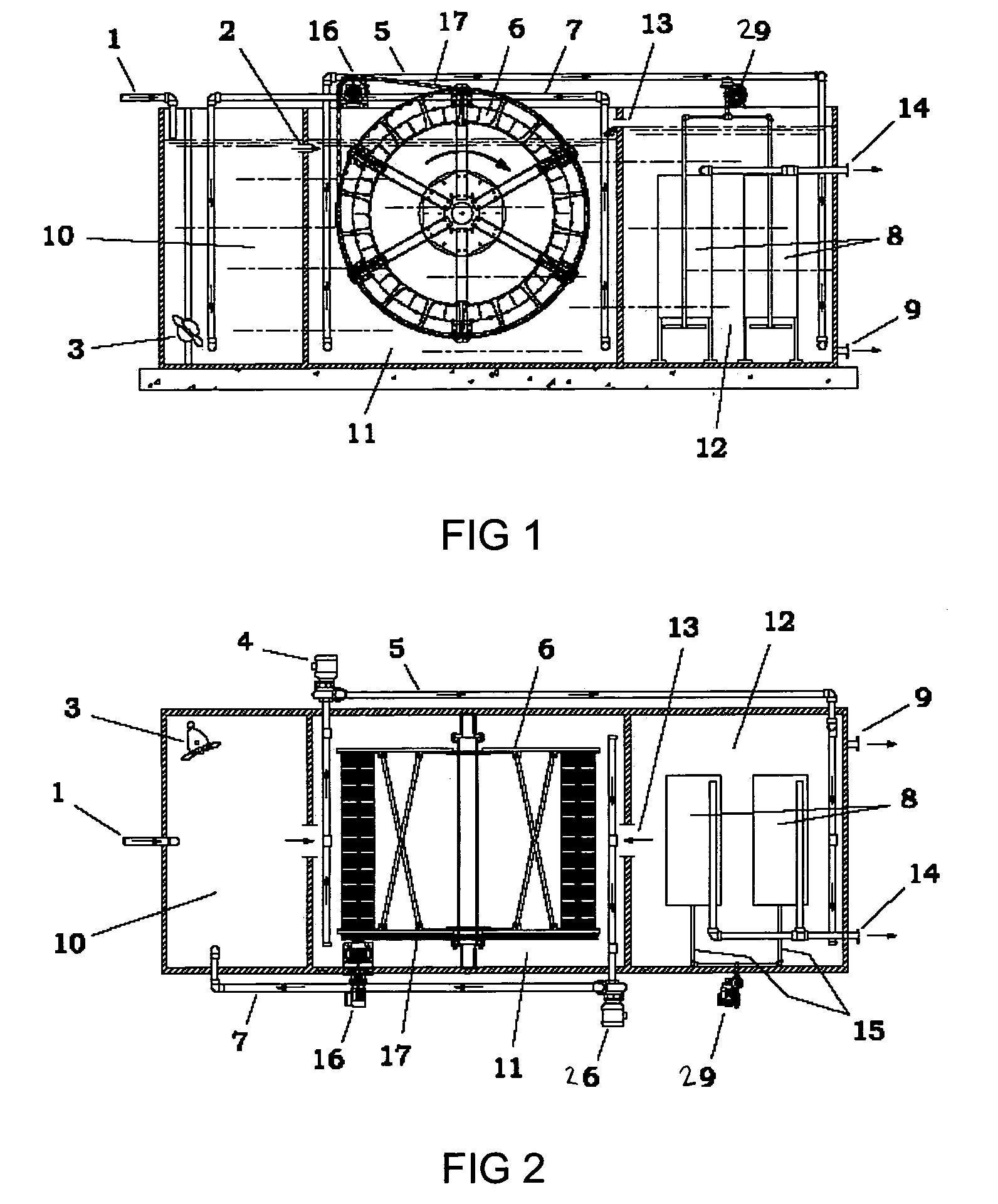

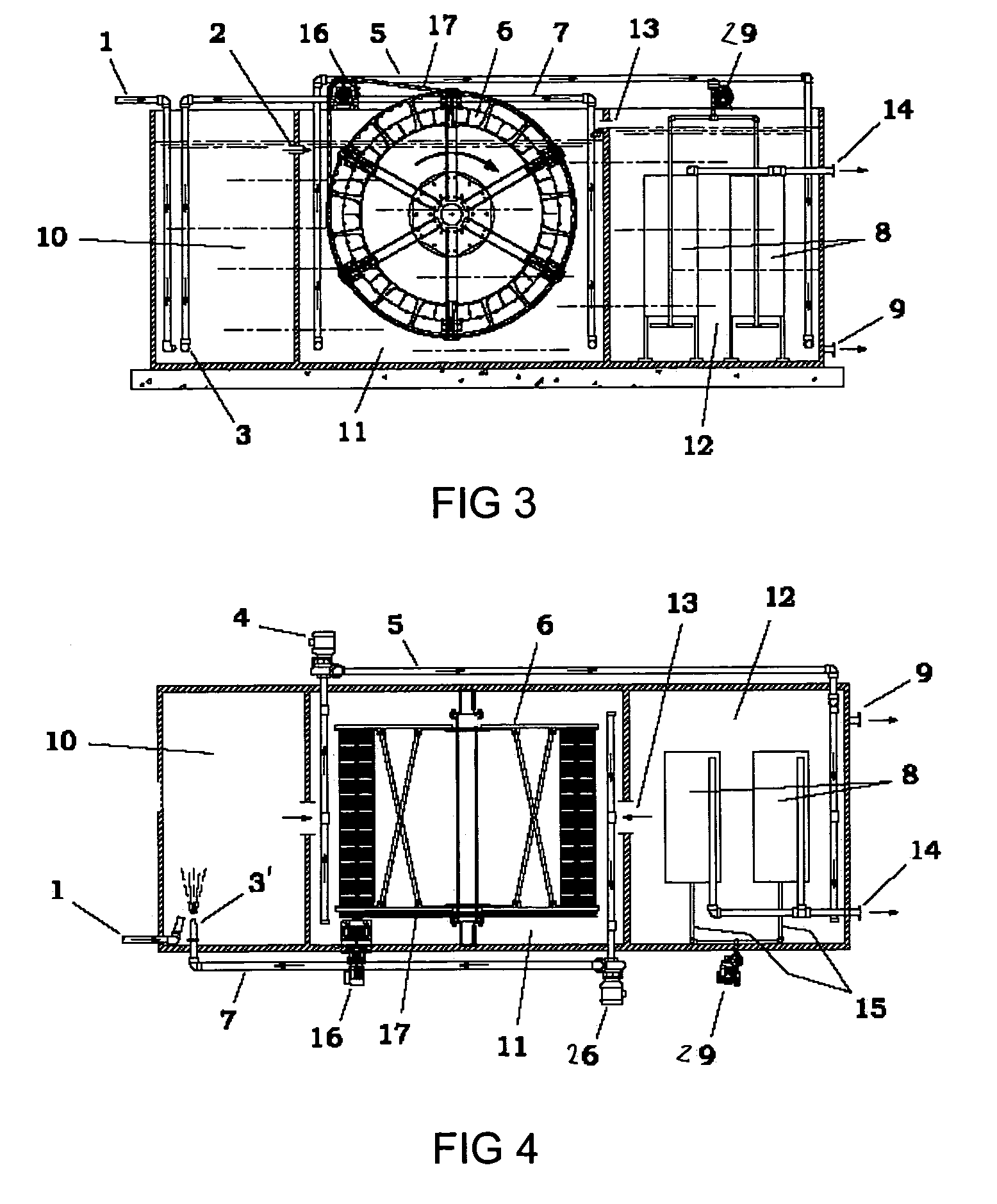

[0021]FIG. 1 depicts a cross-sectional side view of a waste treatment apparatus, with FIG. 2 showing a plan view. Raw domestic or suitable industrial wastewater enters through a pipe 1 and flows into an anoxic denitrification tank 10, where the wastewater typically mixes with sludge to form a mixed liquor to remove nitrogen compounds.

[0022]The sludge, which typically contains viable bacteria and microorganisms, reacts with the wastewater in the anoxic basin to further the activated sludge process, including denitrification.

[0023]Following treatment in anoxic denitrification tank 10, water overflows by gravity through opening 2 into an aeration tank 11, which may or may not be replaced by or supplemented with a pump. Typically, aeration tank 11 includes a rotary aerator 6, such as a BIO-WHEEL apparatus, as described in U.S. Pat. Nos. 6,572,774 and 6,613,229 (each of which is expressly incorporated herein in its entirety). Although less preferred, it is considered within the scope of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap