Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "COTTON WOOL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On a twin bed covered by a thin clear plastic sheet, sat a bag with surgical gloves, a jar of petroleum jelly, cotton wool, some pain killers and the needle, attached to a long, thin tube, which is used to drain the fluid into a bucket on the floor. — Alex Platt, CNN, "Trump's ban on global ...

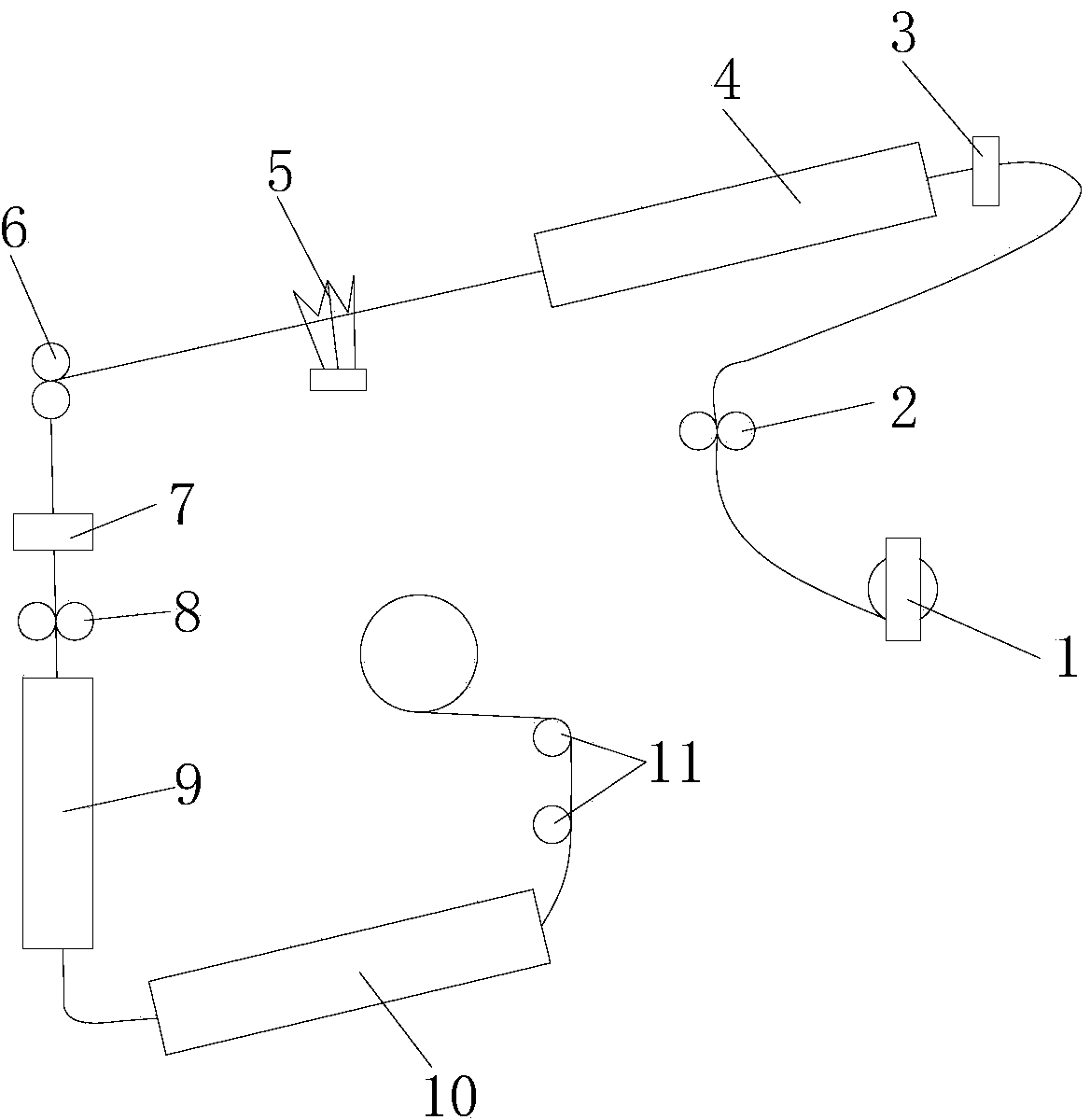

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

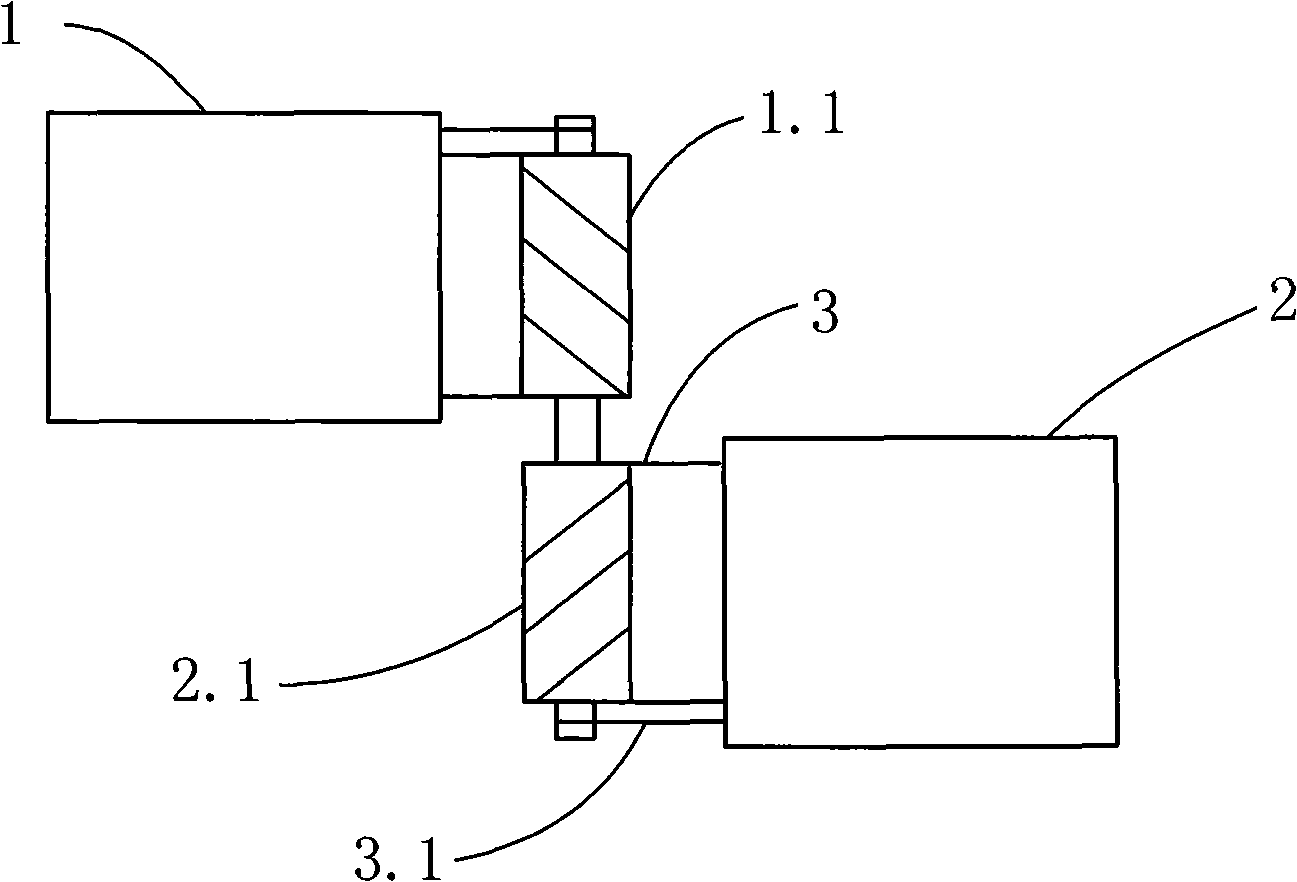

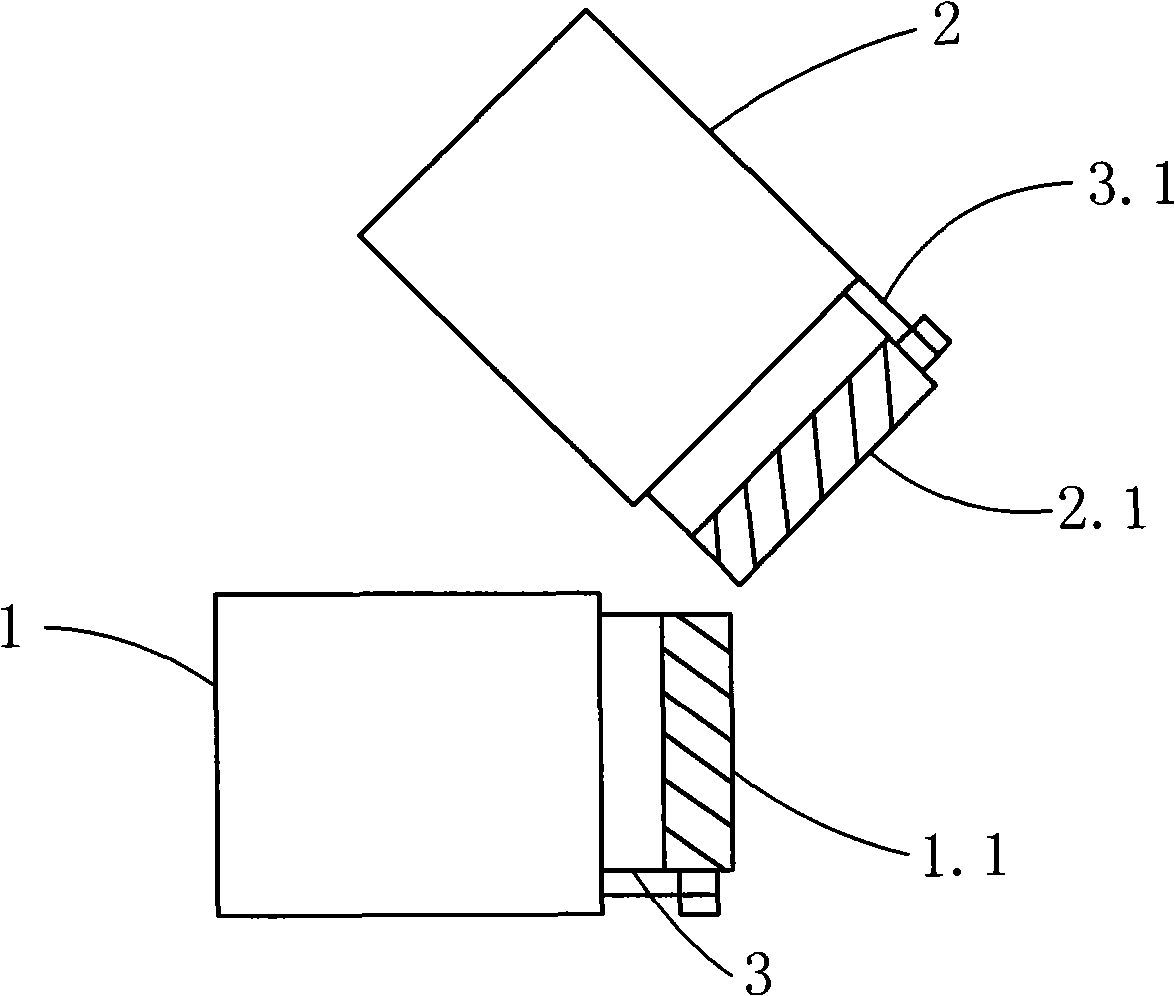

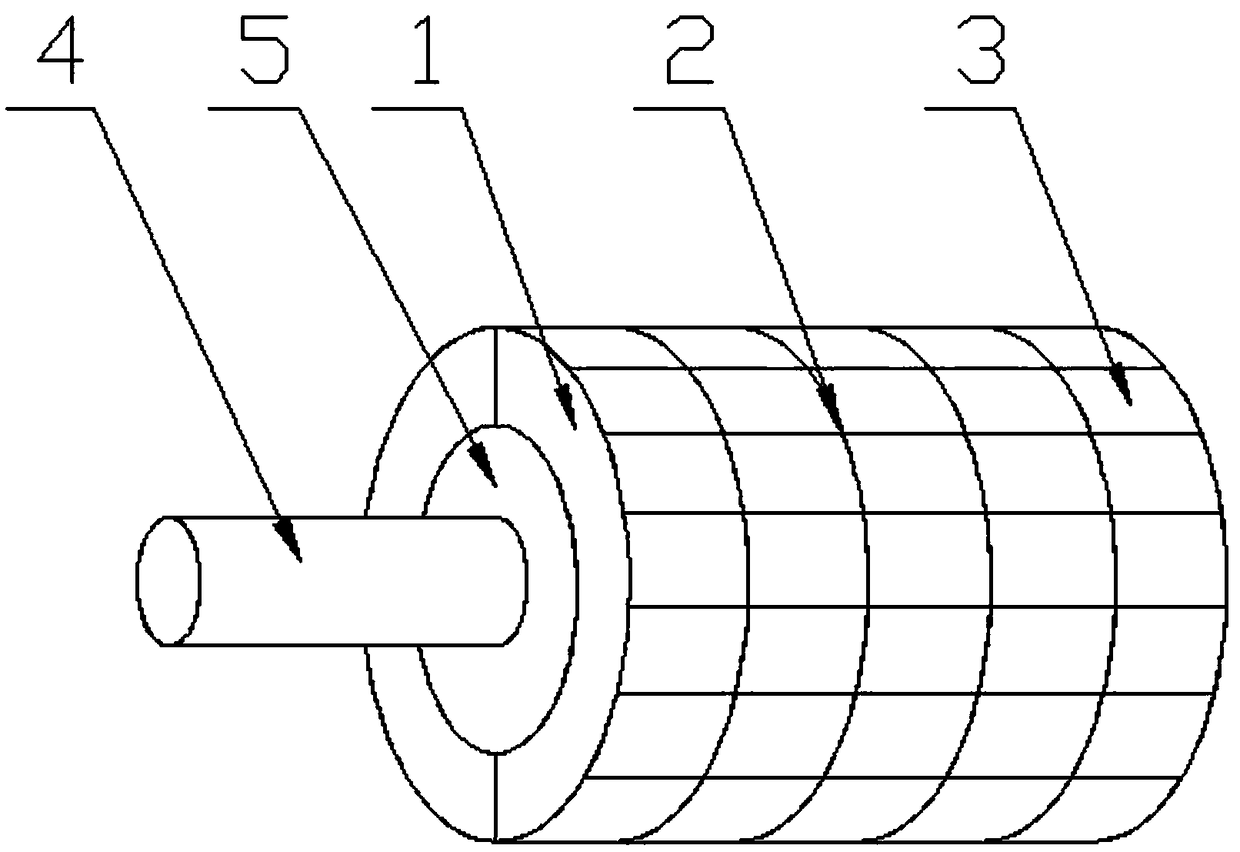

Wadding machine and processing method for cotton slice

InactiveCN101279706AImprove cohesionSeamlessBed-coversUpholstery fillingWaddingThin layer

Owner:任文生

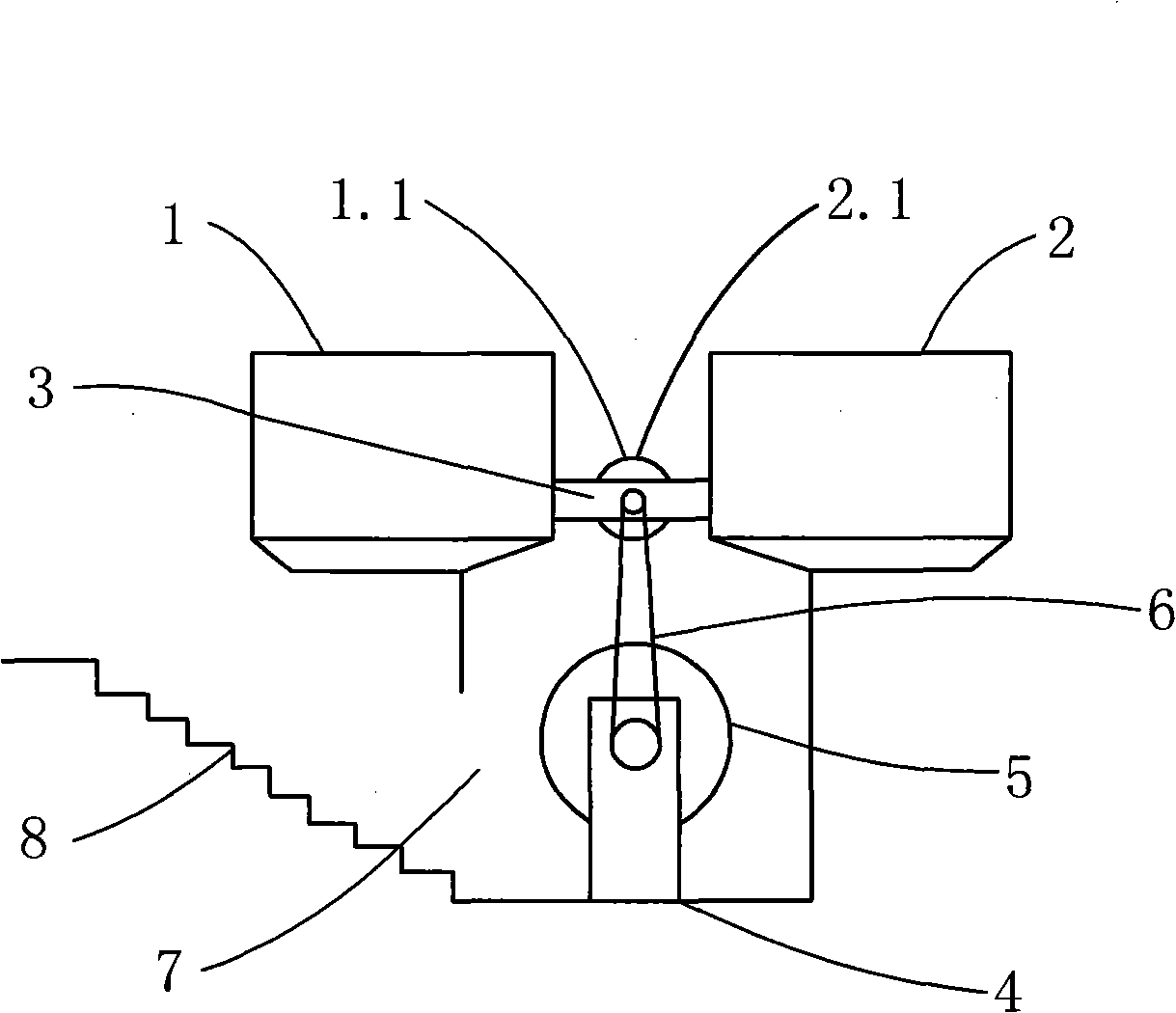

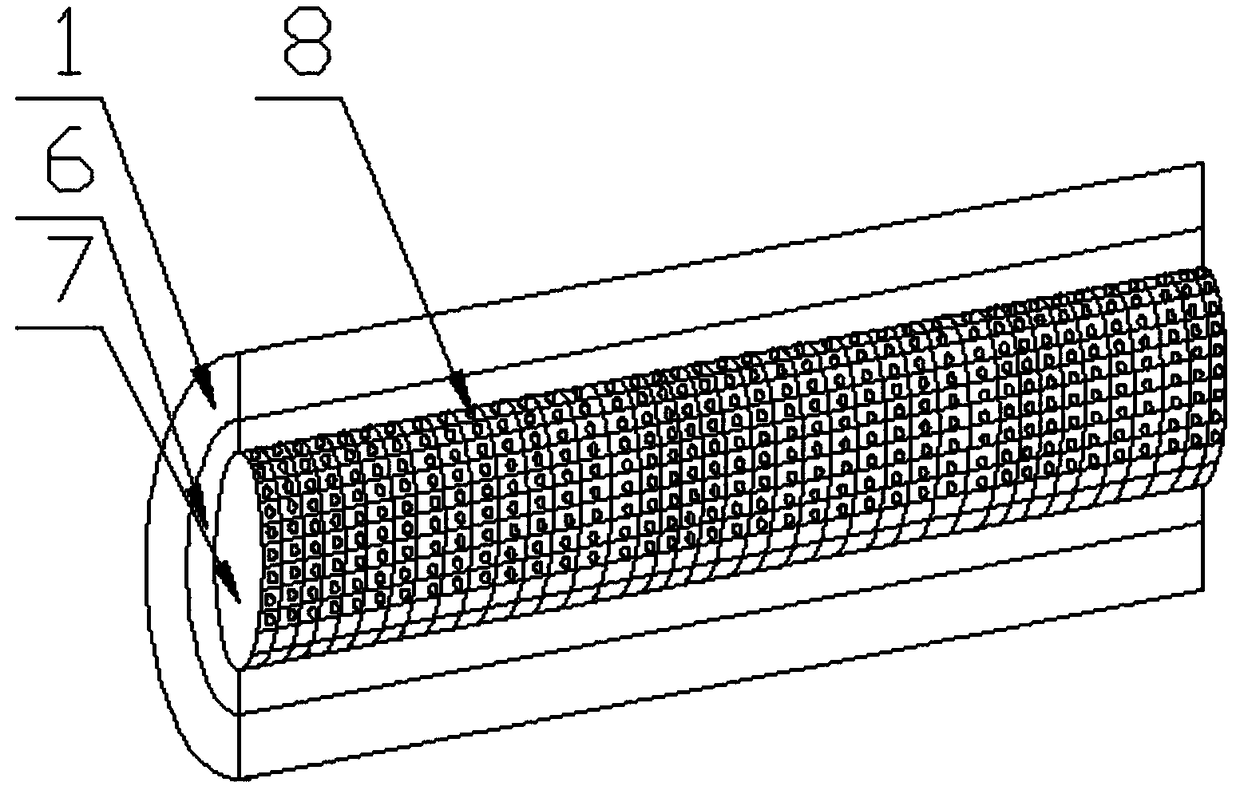

Braided cotton roll for dental operation

InactiveCN109009673AAvoid secondary infectionGood hemostatic effectDentistrySurgerySecondary InfectionsEngineering

Owner:东台市华鑫福利色织厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap