Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process requirements refer to a documented statement of needs a business organization intends to satisfy by identifying methodologies, approaches and techniques to be applied to producing a certain outcome (product or service) that materializes or realizes the initially stated needs.

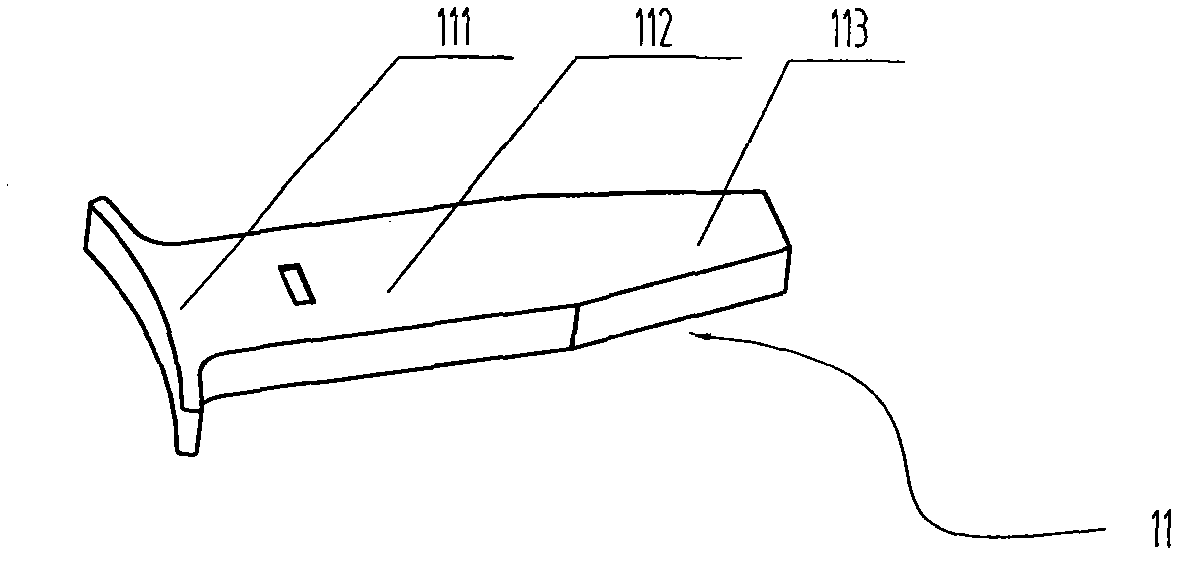

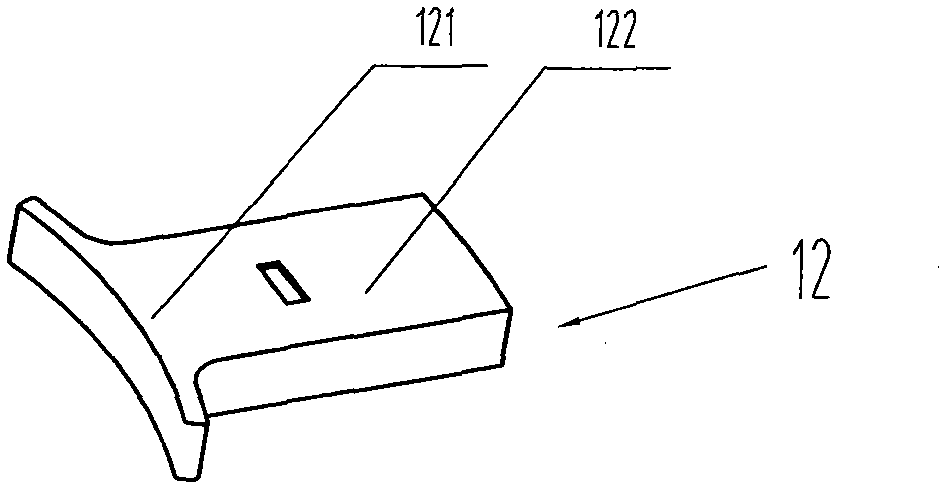

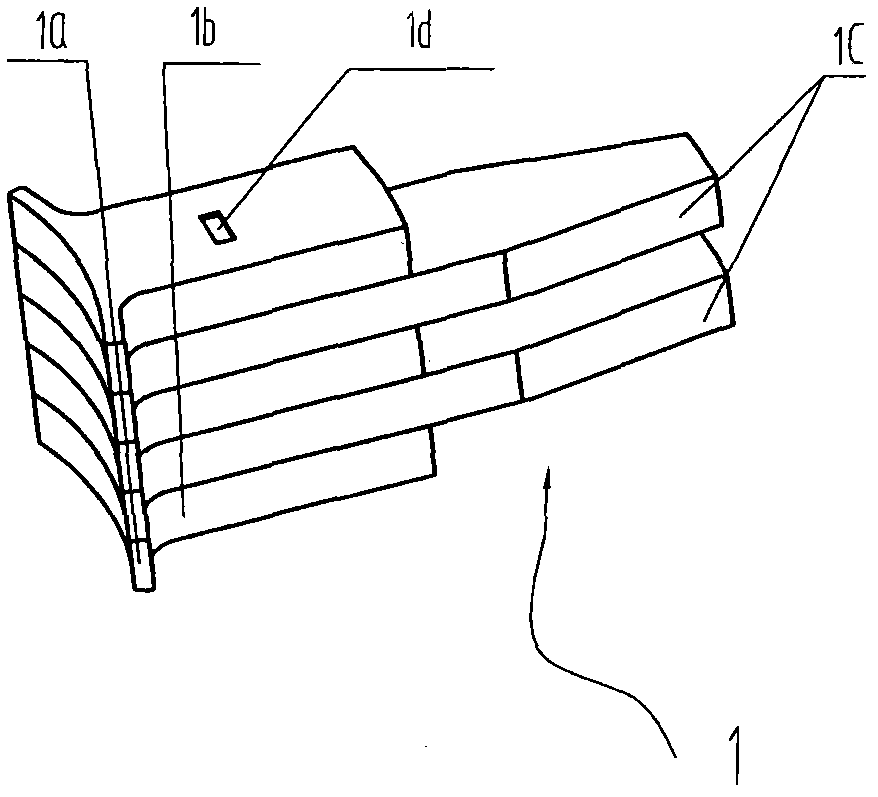

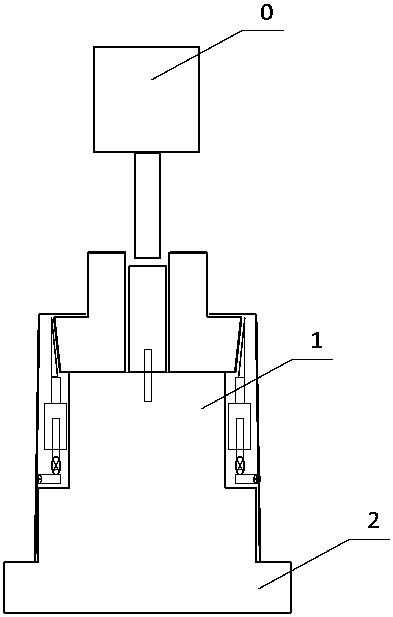

Laminated laminated stator and manufacturing method thereof

ActiveCN102280977AConvenient winding operationFree from space interferenceManufacturing stator/rotor bodiesEngineeringPole piece

Owner:浙江迪贝电气股份有限公司

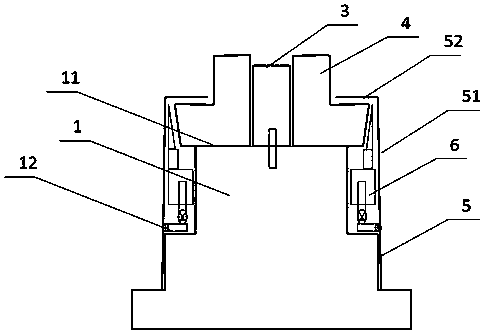

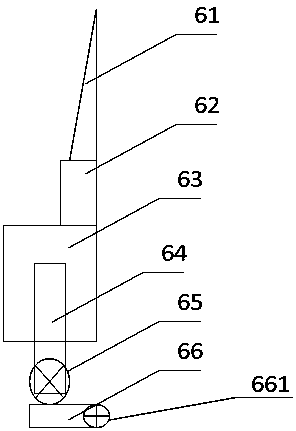

Metal sheet no-rivet connecting tool

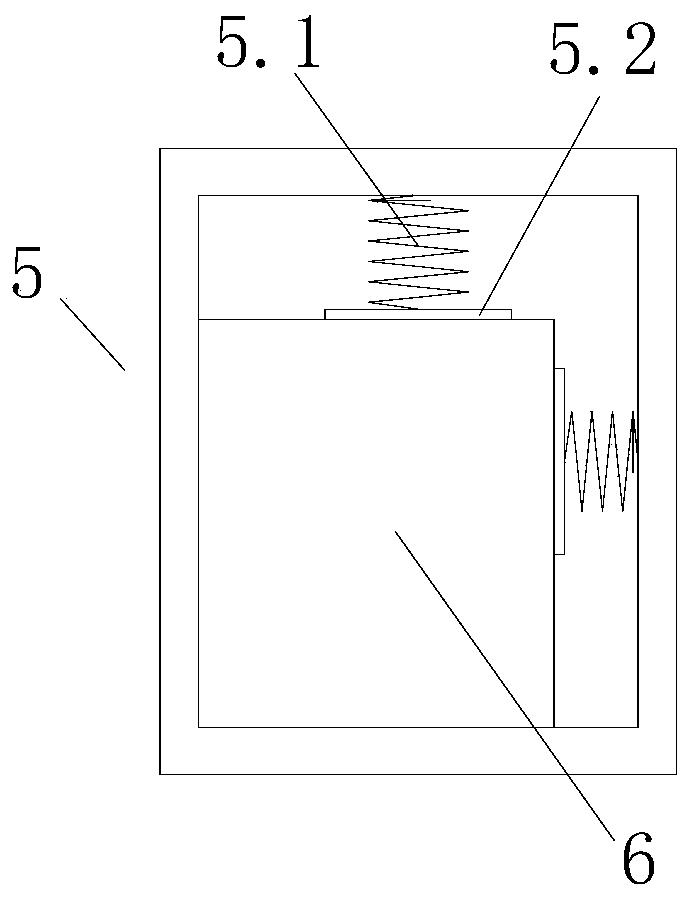

The invention provides a metal sheet no-rivet connecting tool. The metal sheet no-rivet connecting tool comprises a first tool assembly provided with a punch and a second tool assembly provided with apressing die, and an anvil and a pressing die body are detachably connected. An elastic regulating device is arrange between a movable pressing die element and an elastic element, an arc section of the lower portion of the outer side of the movable pressing die element is designed to be a cone portion, an elastic abuts against a compensation arm of an arc inclined wedge piece laterally, and the compensation arm of the arc inclined wedge piece abuts against the cone portion of the movable pressing die element to transmit elastic force to the movable pressing die element. The elastic regulatingdevice further comprises a worm wheel and a worm, the worm wheel is fixedly connected with a screw, the worm wheel is driven by the worm, and the screw is driven by the worm to move up and down. Diffident anvils can be replaced according to different process requirements, and the movable pressing die element is not required to be placed. The metal sheet no-rivet connecting tool realizes the technical effects of low cost, wide range of application and adjustable elastic force.

Owner:新沂市邵店众创工贸发展有限公司

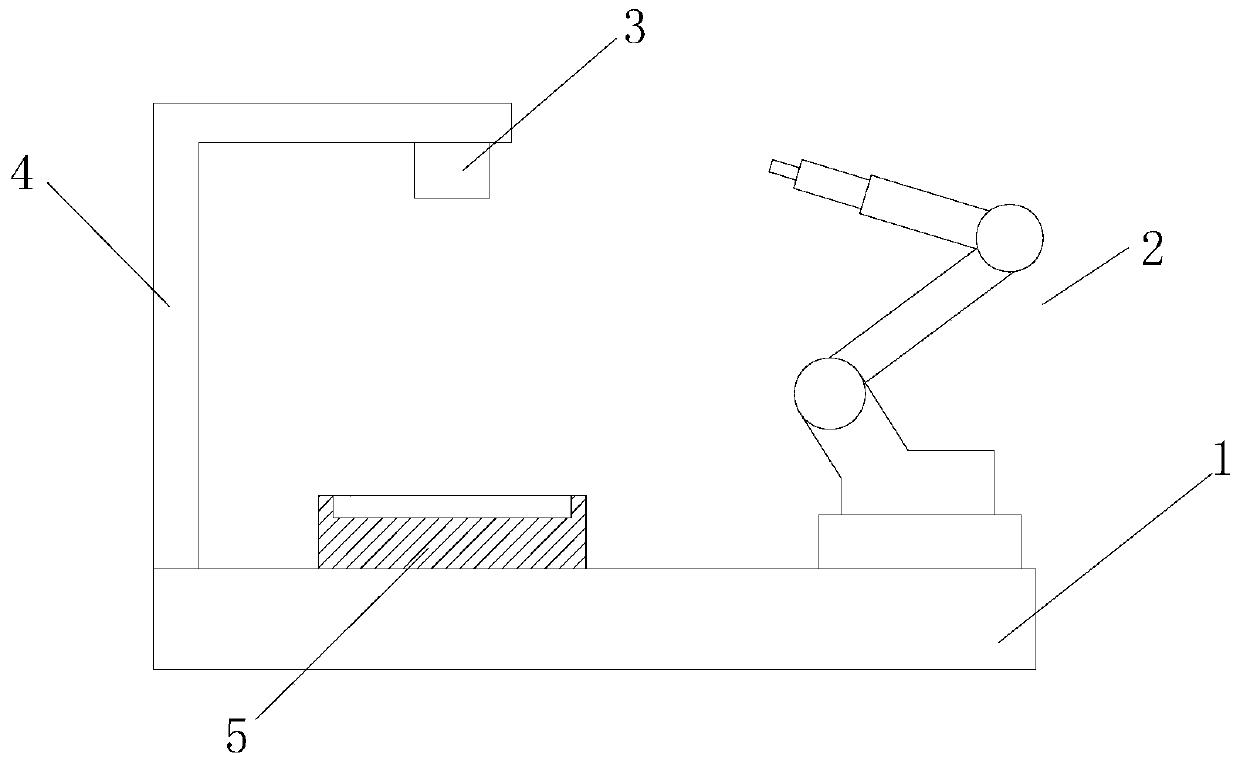

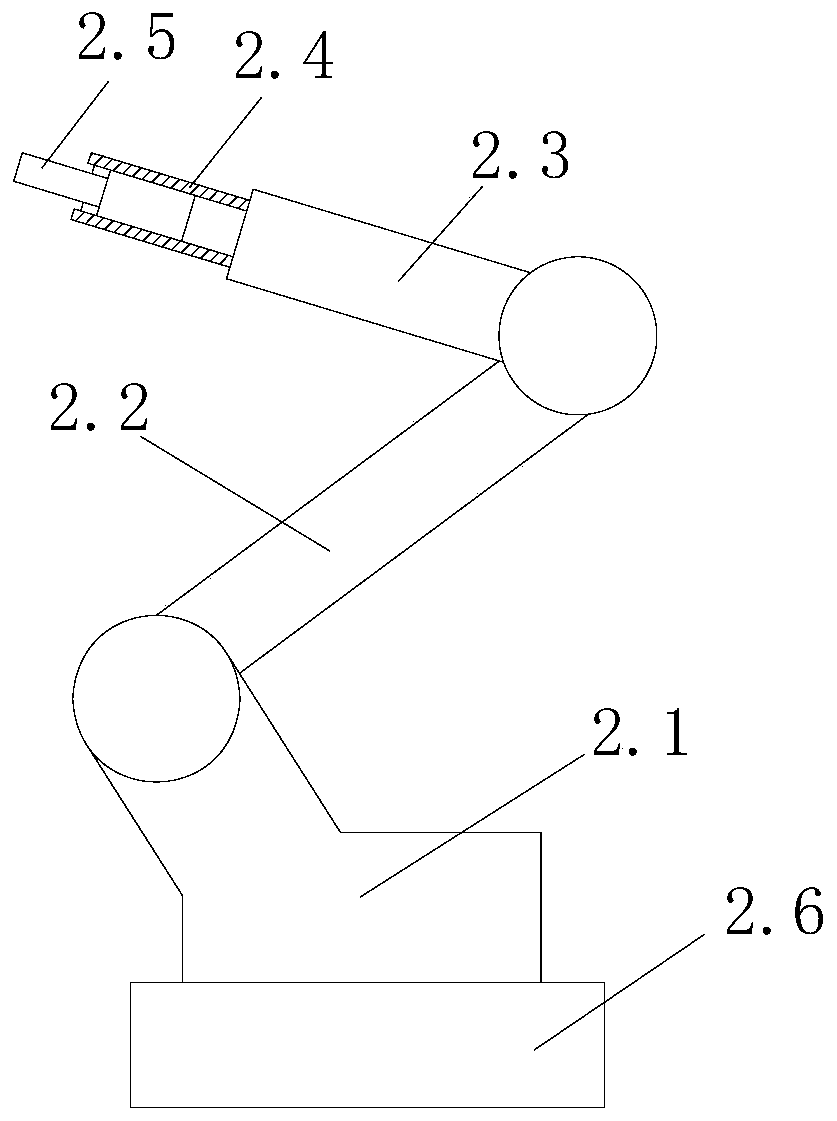

Robot plane work point rapid positioning system and rapid positioning method thereof

InactiveCN110228068ASimple structureSimple job trackProgramme-controlled manipulatorEngineeringFuture of robotics

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap