Metal sheet no-rivet connecting tool

A metal plate and riveting connection technology, which is applied in the field of metal plate riveted connection tools, can solve problems such as single function, frequent impact, and non-adjustable elastic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

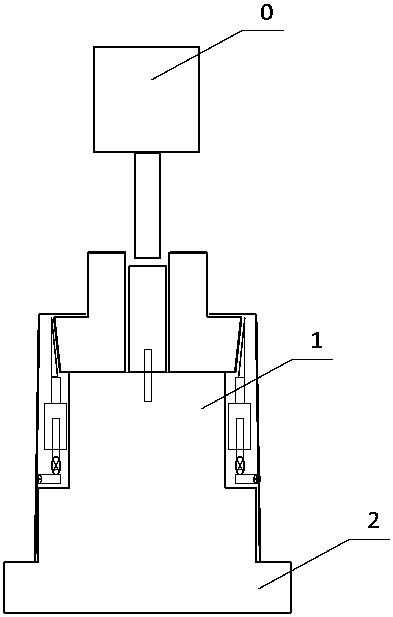

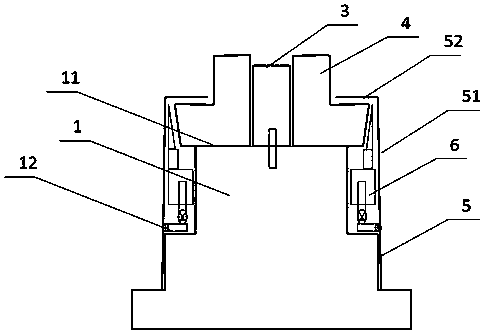

[0029] The present embodiment provides a tool for rivetless joining of metal sheets, comprising: two separate tool parts, a first tool part O with a punch, and a second tool part provided with a die, the punch is arranged to press along The mold is driven in the direction of the axis for linear motion, and the first tool part O and the second tool part cooperate to make the joint;

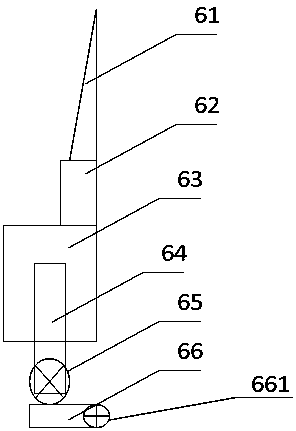

[0030] An anvil 3 is arranged on the top of the die, and the die is further provided with a die body 1, a die seat 2 and a movable die element 4, which is arranged to resist the force from the elastic element 5, perpendicular to the die the length axis of the die body 1 slides laterally on a support surface arranged on the top surface 11 of the die body 1 , the height of the end face of the anvil 3 being smaller than the height of the end face of the movable die element 4;

[0031] The die comprises at least two movable die elements 4, the elastic elements 5 have the form of a cylindrical cage, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap