Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Support surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Support surface is any material, such as a mattress, that supports people who are bed-ridden through illness. Research and development of appropriate support surfaces can alleviate some of the complications of immobility, such as bedsores and respiratory problems.

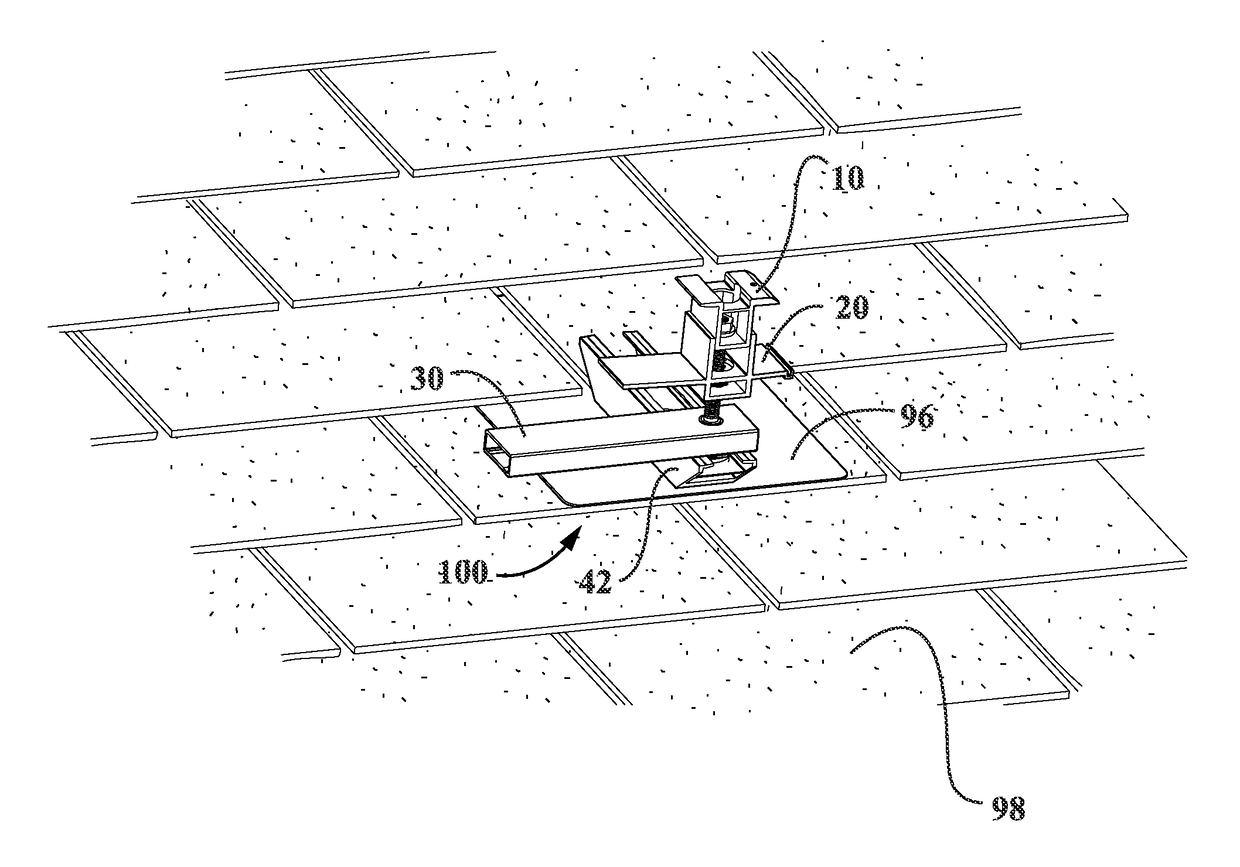

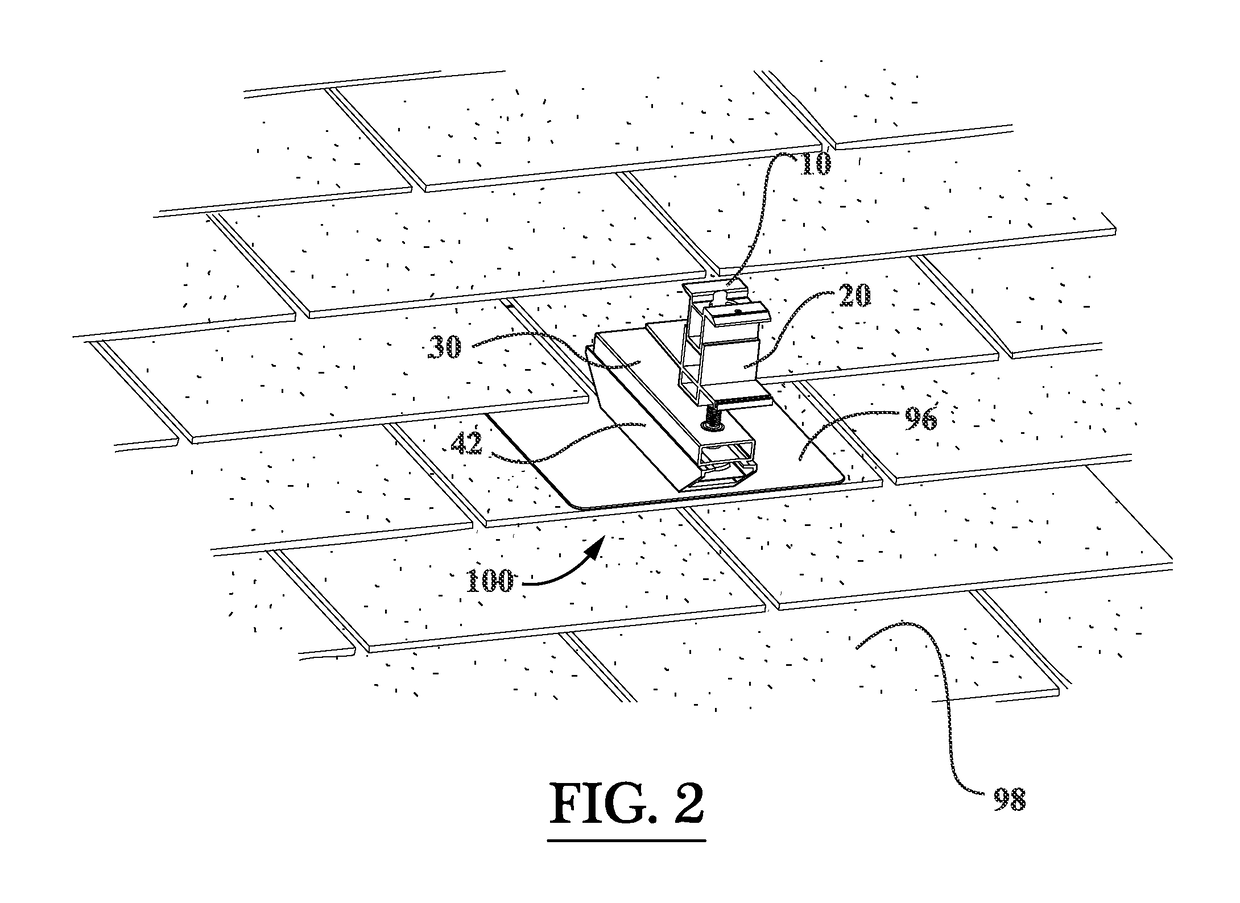

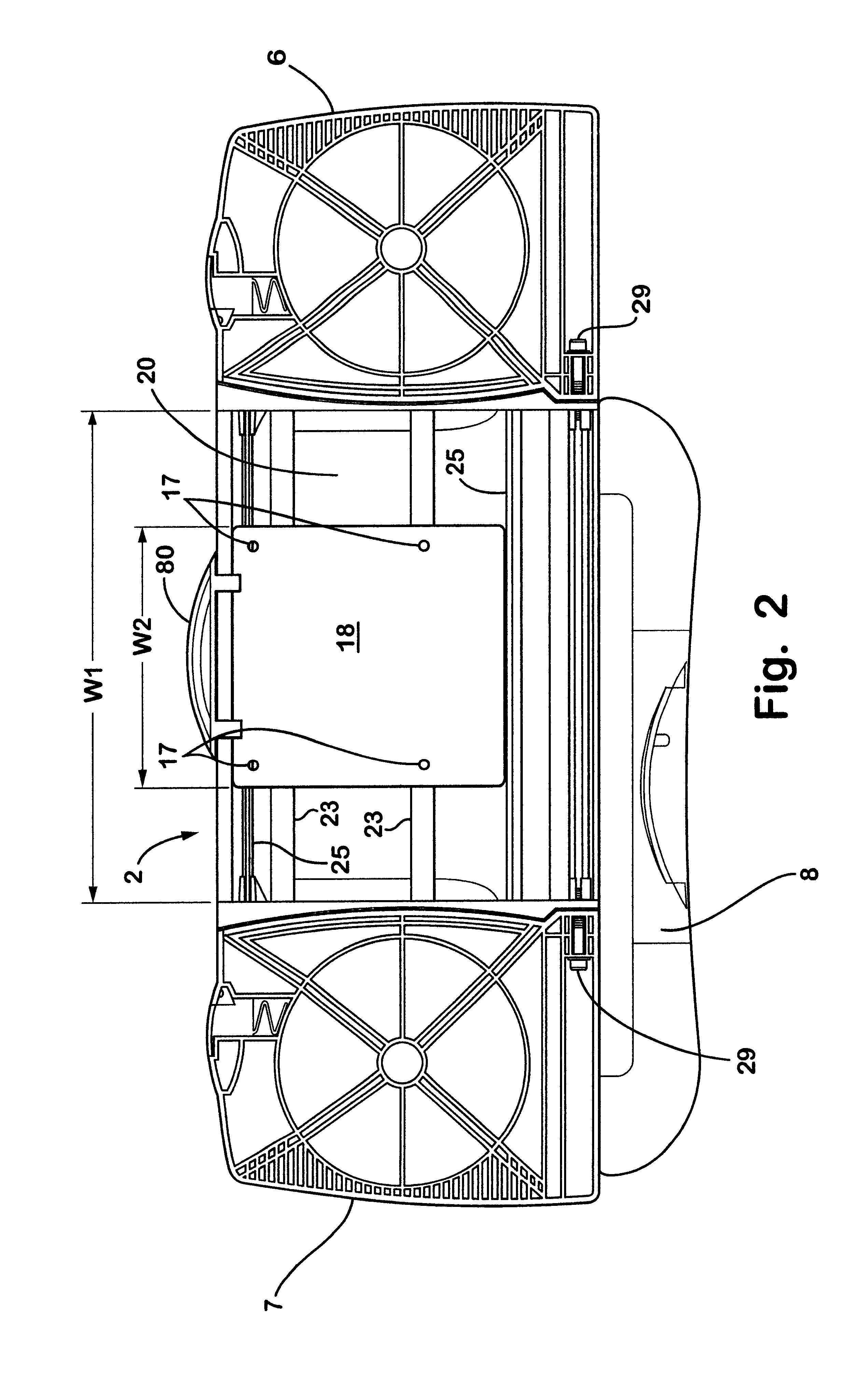

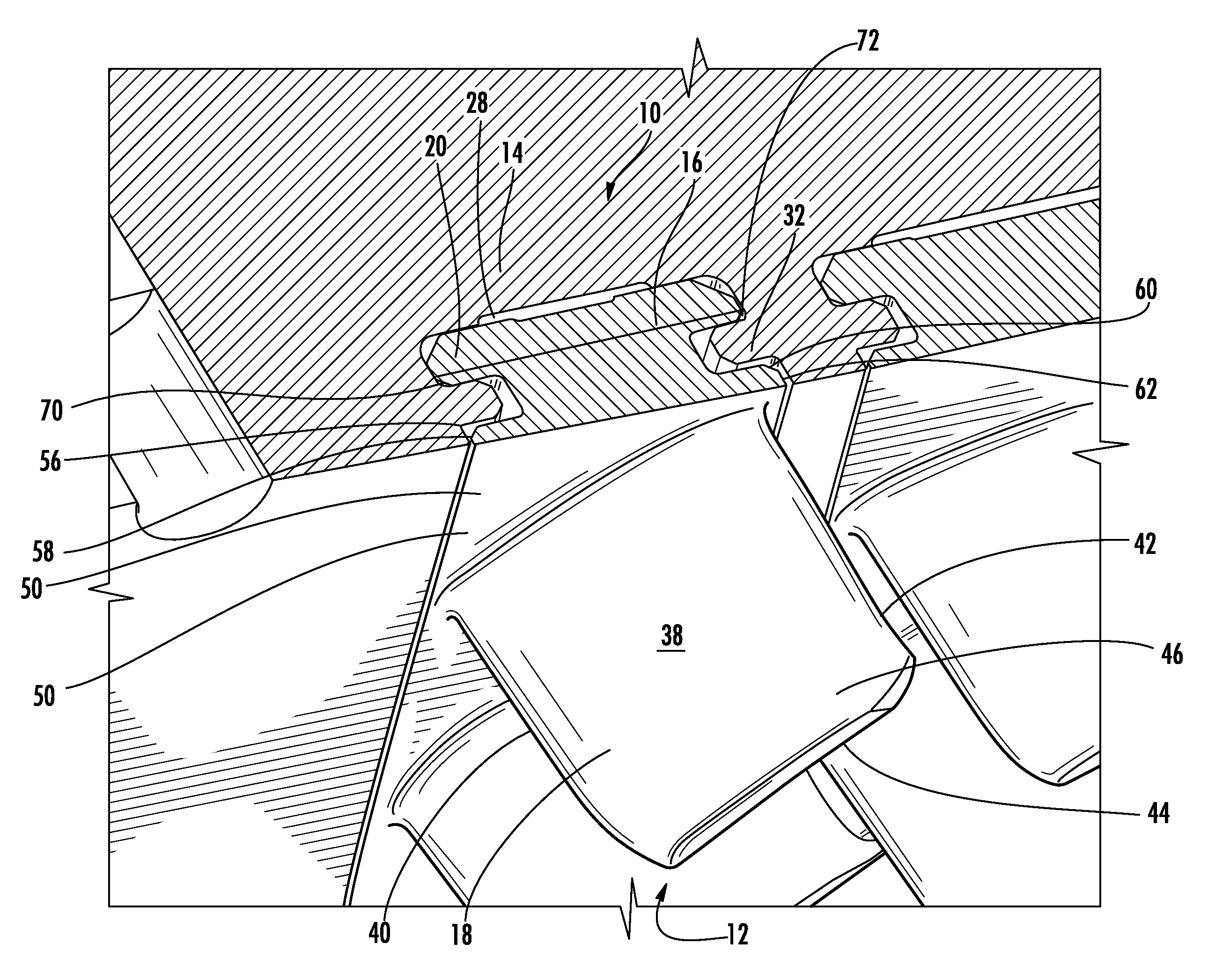

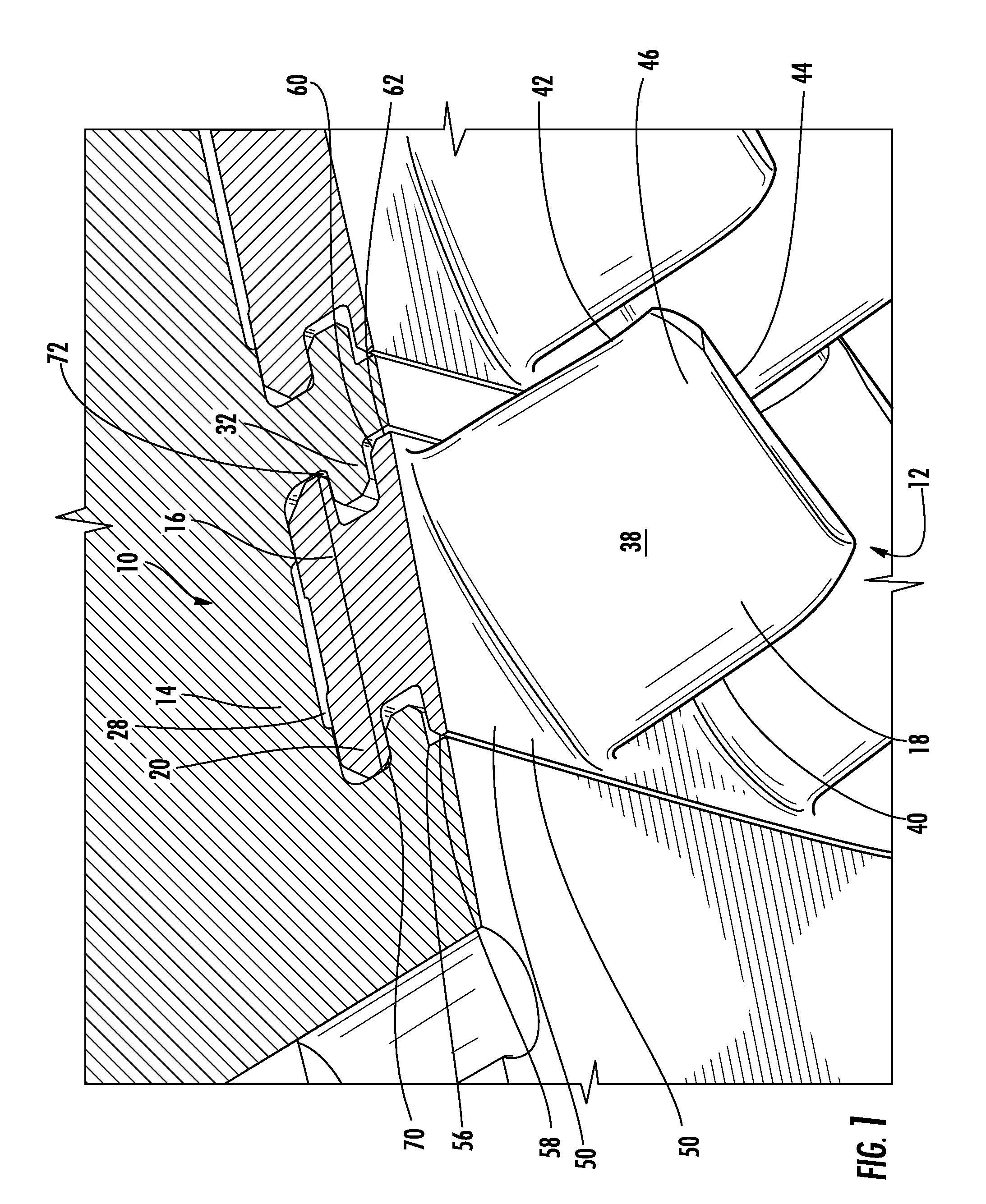

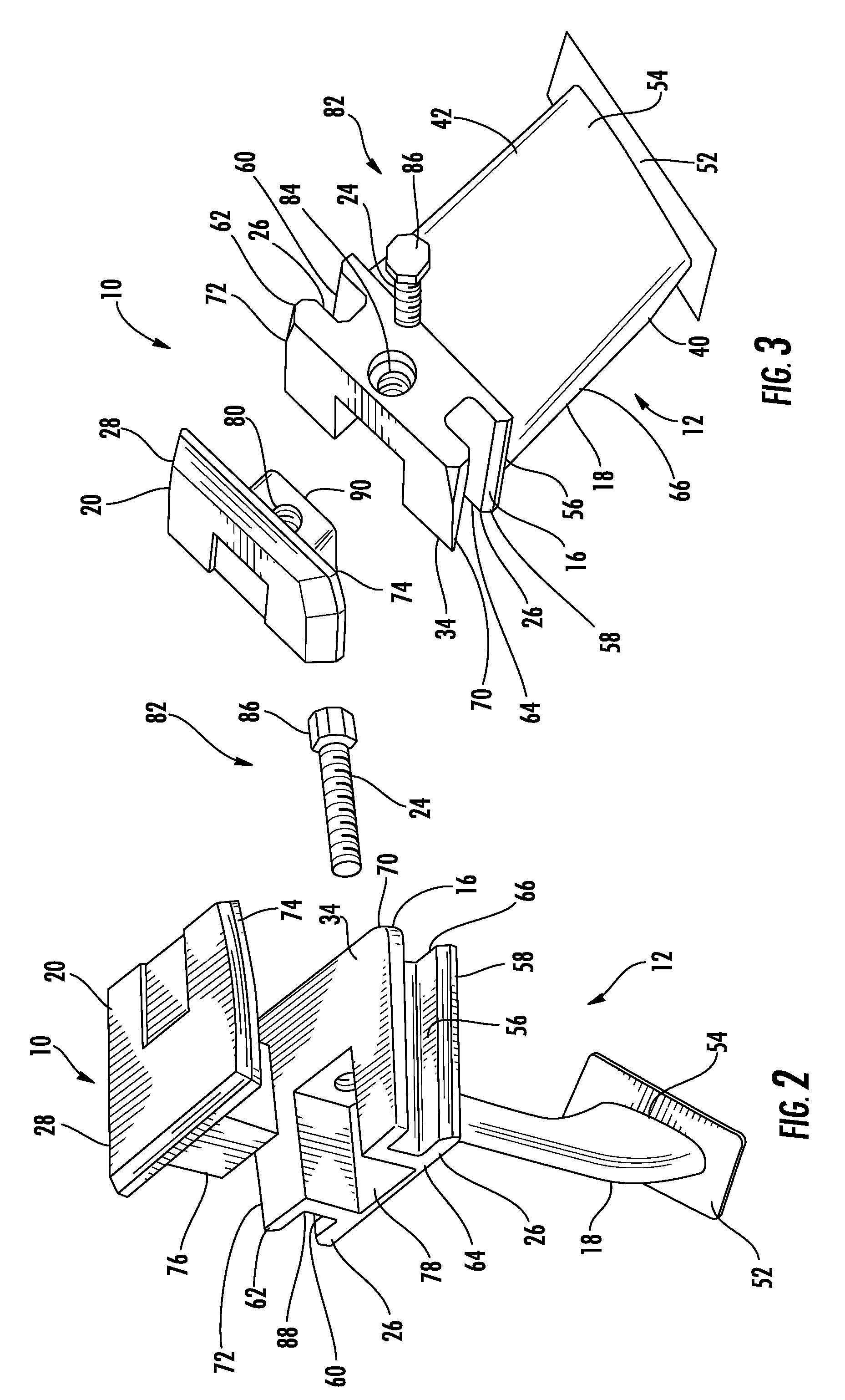

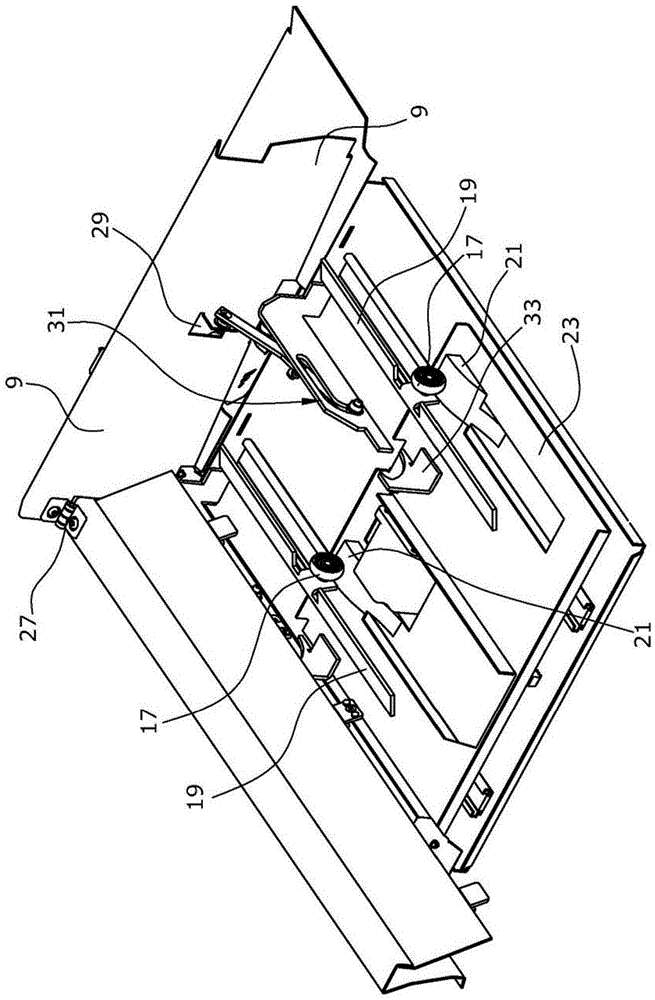

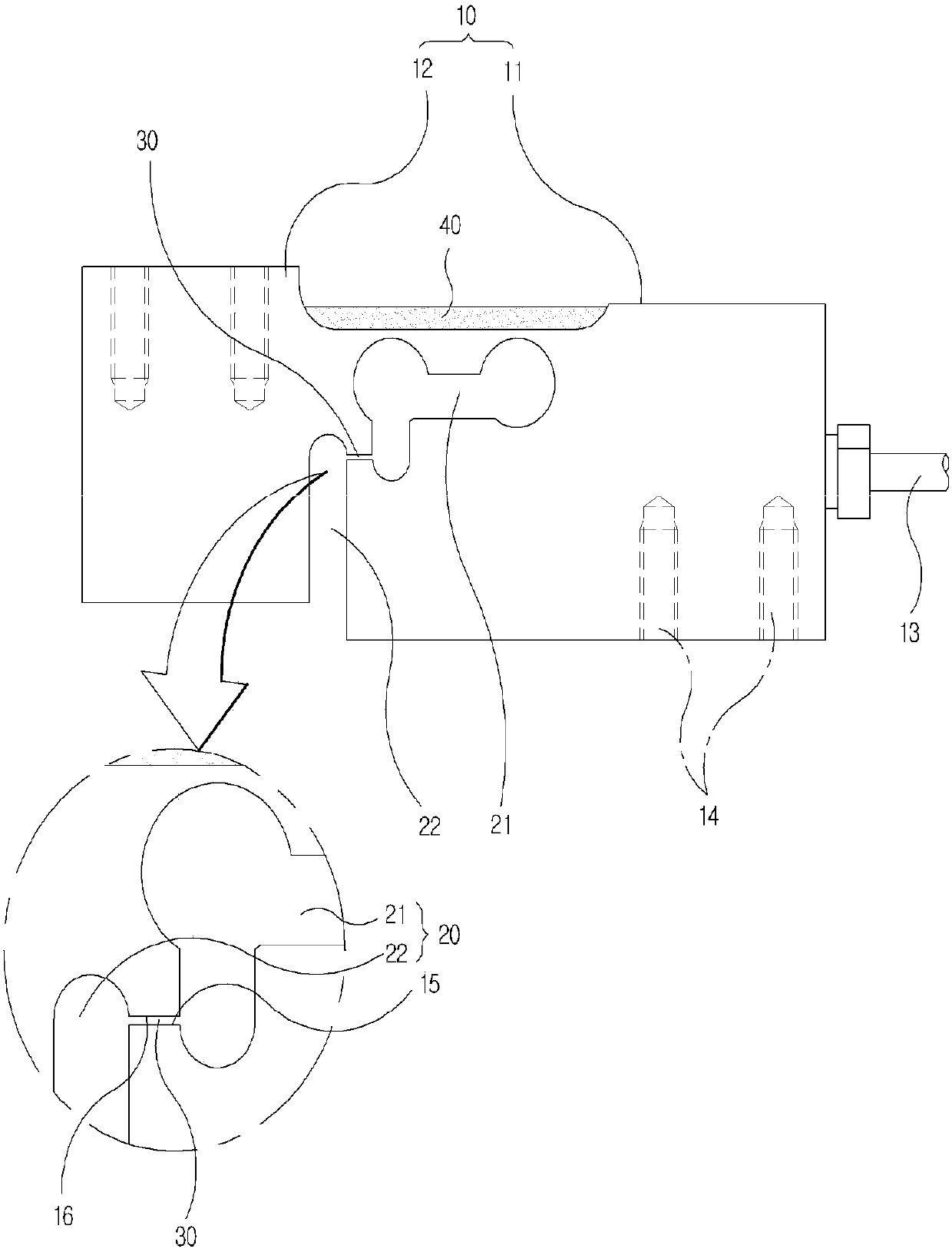

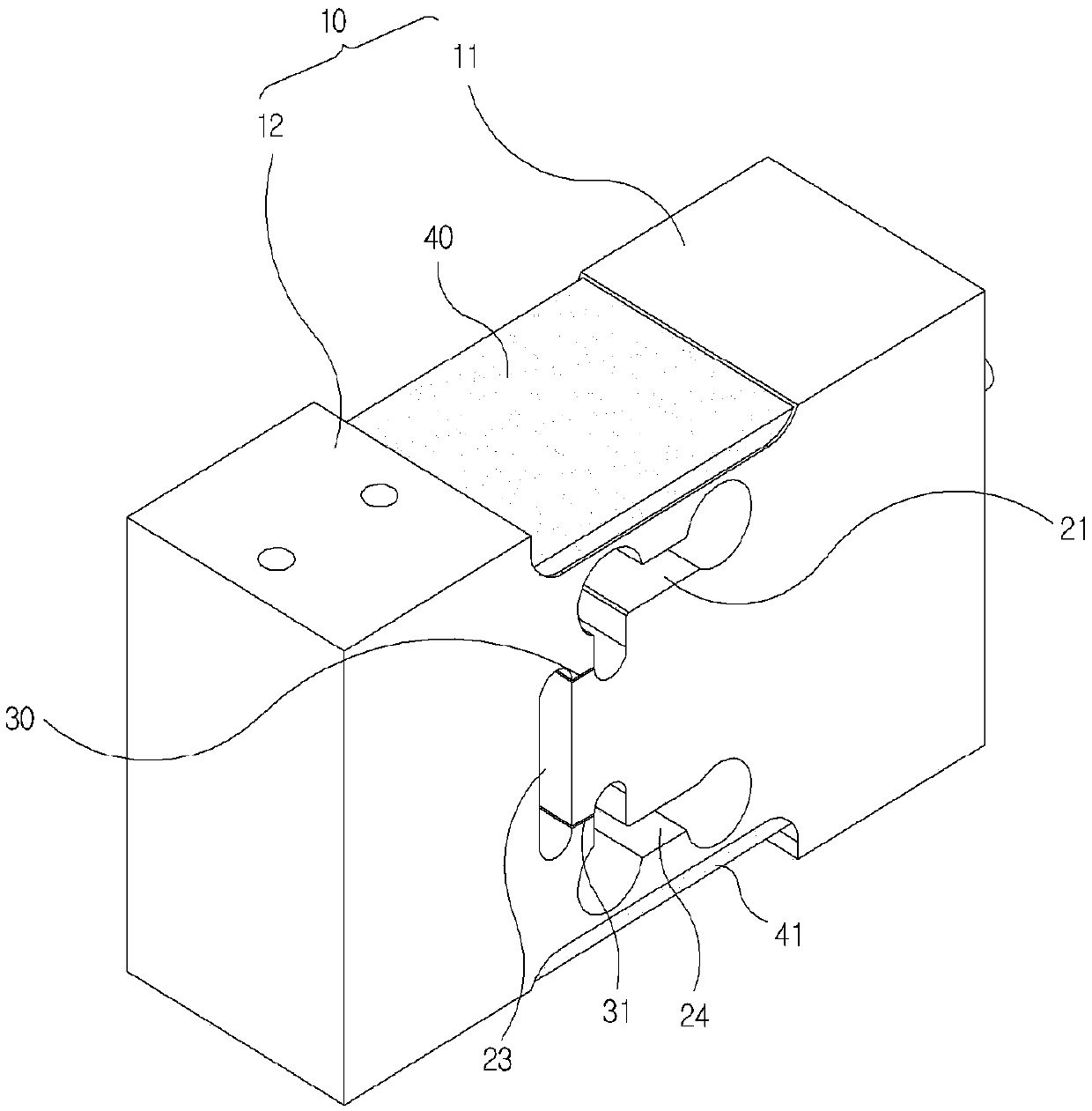

Modular sloped roof solar mounting system

ActiveUS9825581B2Avoid passingSecure retentionSolar heating energyPhotovoltaic supportsCouplingModularity

Owner:UNIRAC INC

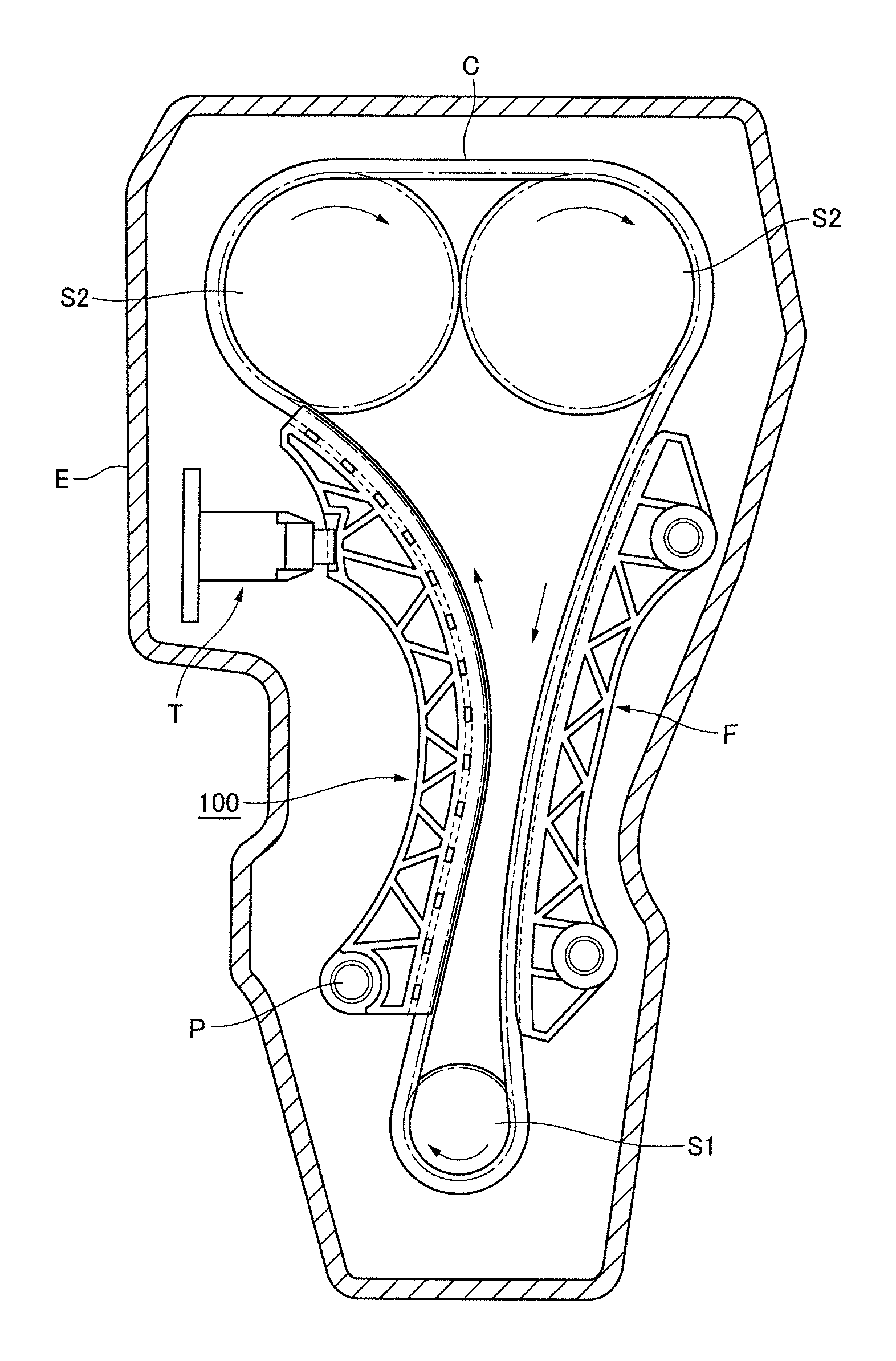

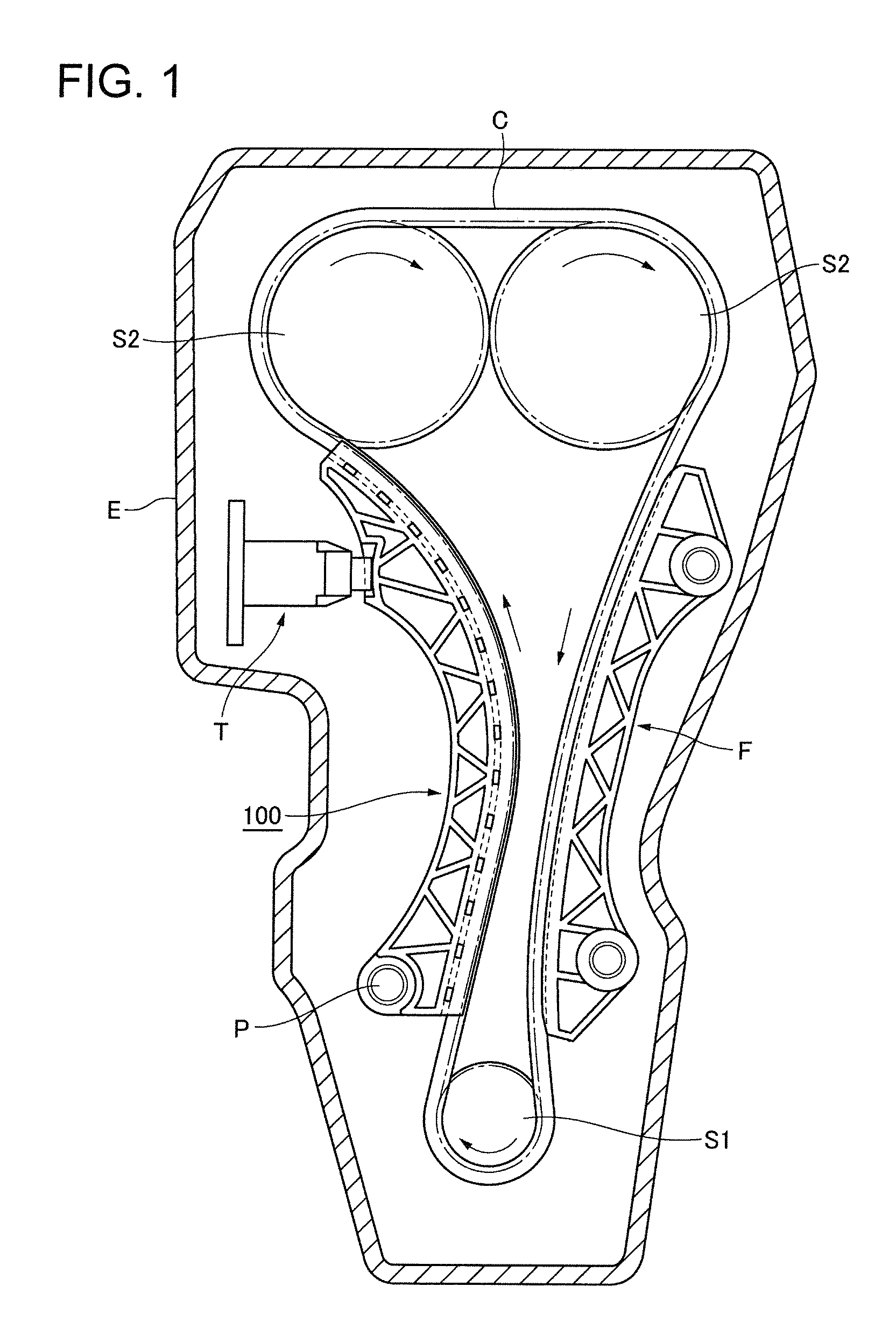

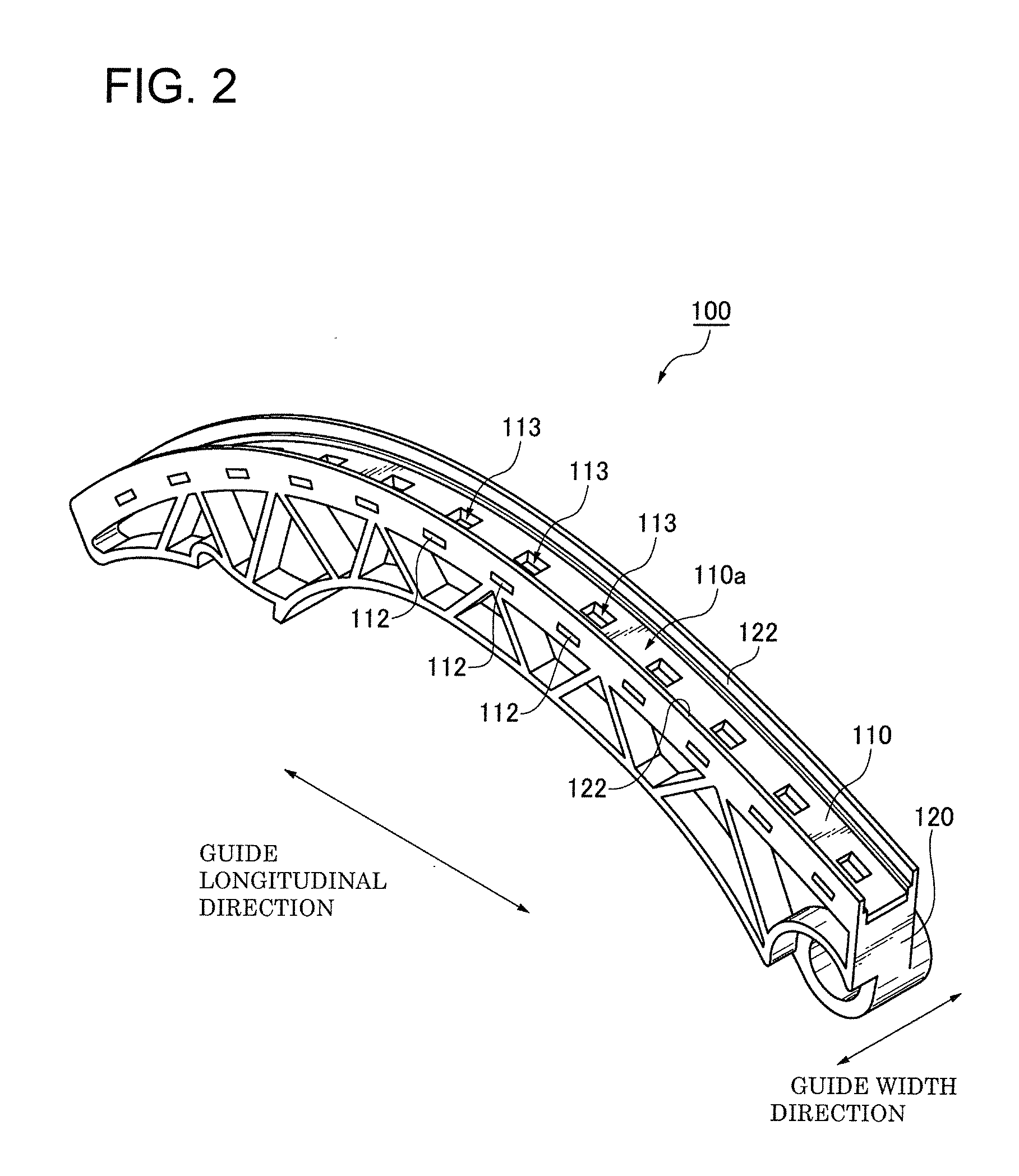

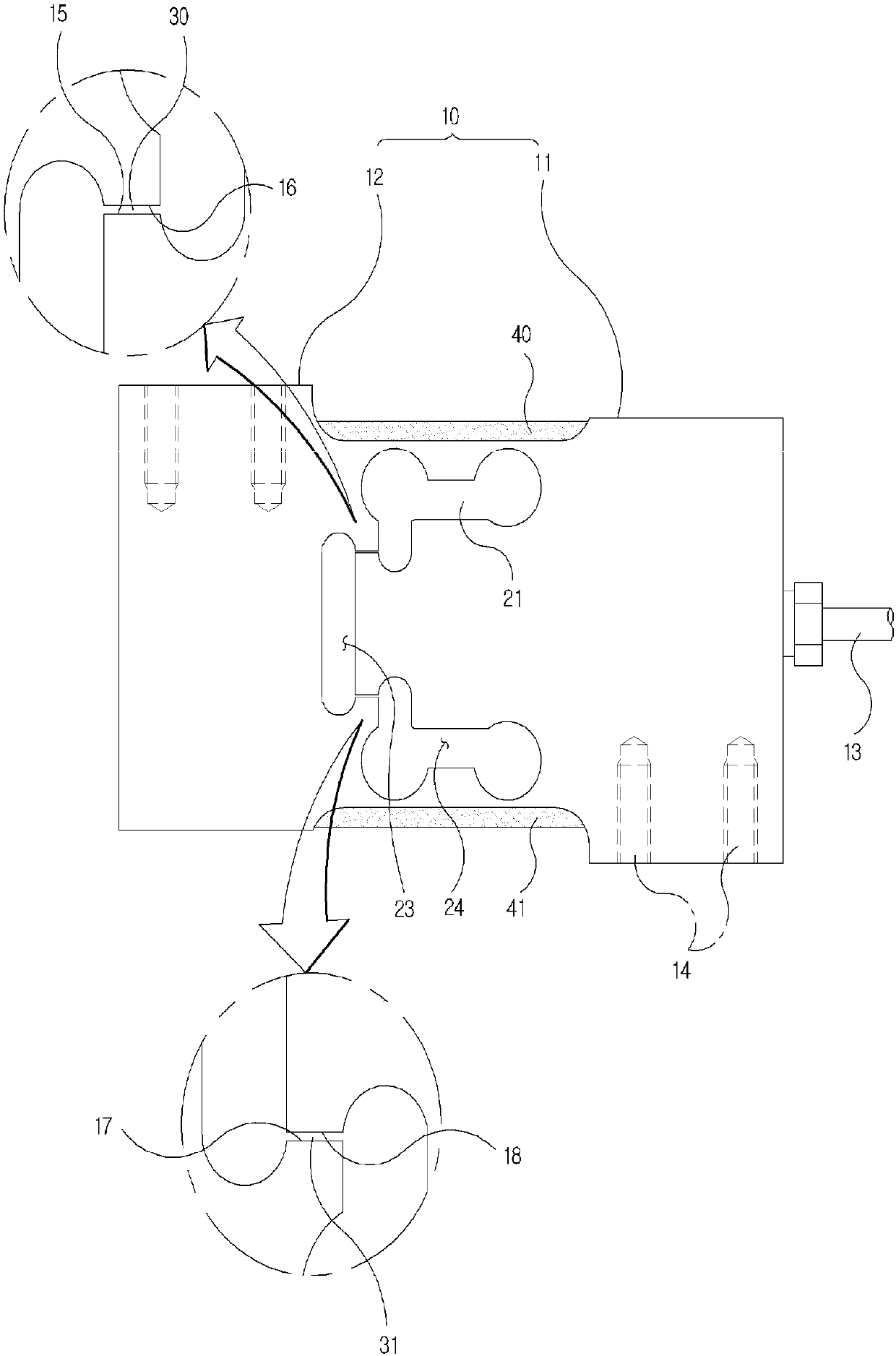

Transmission guide

Owner:TSUBAKIMOTO CHAIN CO

System and method for planning and/or producing a dental prosthesis

ActiveUS20120284000A1Eliminate needDental implantsAnalogue computers for chemical processesData simulationCode segment

A method, system and computer program of planning a dental prosthesis in a patient are disclosed, including steps, units or code segments for virtually planning a dental prosthesis. Envelope data is provided of an envelope guide, including data corresponding to a support surface for facial tissue, which is desired to result when the dental prosthesis is installed in the oral cavity of the patient. An outer envelope of a desired dental prosthesis in the oral cavity is simulated based on the envelope data. A desired dental restoration is provided and adjusted in a virtual environment relative to the simulated outer envelope, and dental prosthesis data is generated based on the adjusted desired dental restoration usable for producing the dental prosthesis.

Owner:NOBEL BIOCARE SERVICES AG

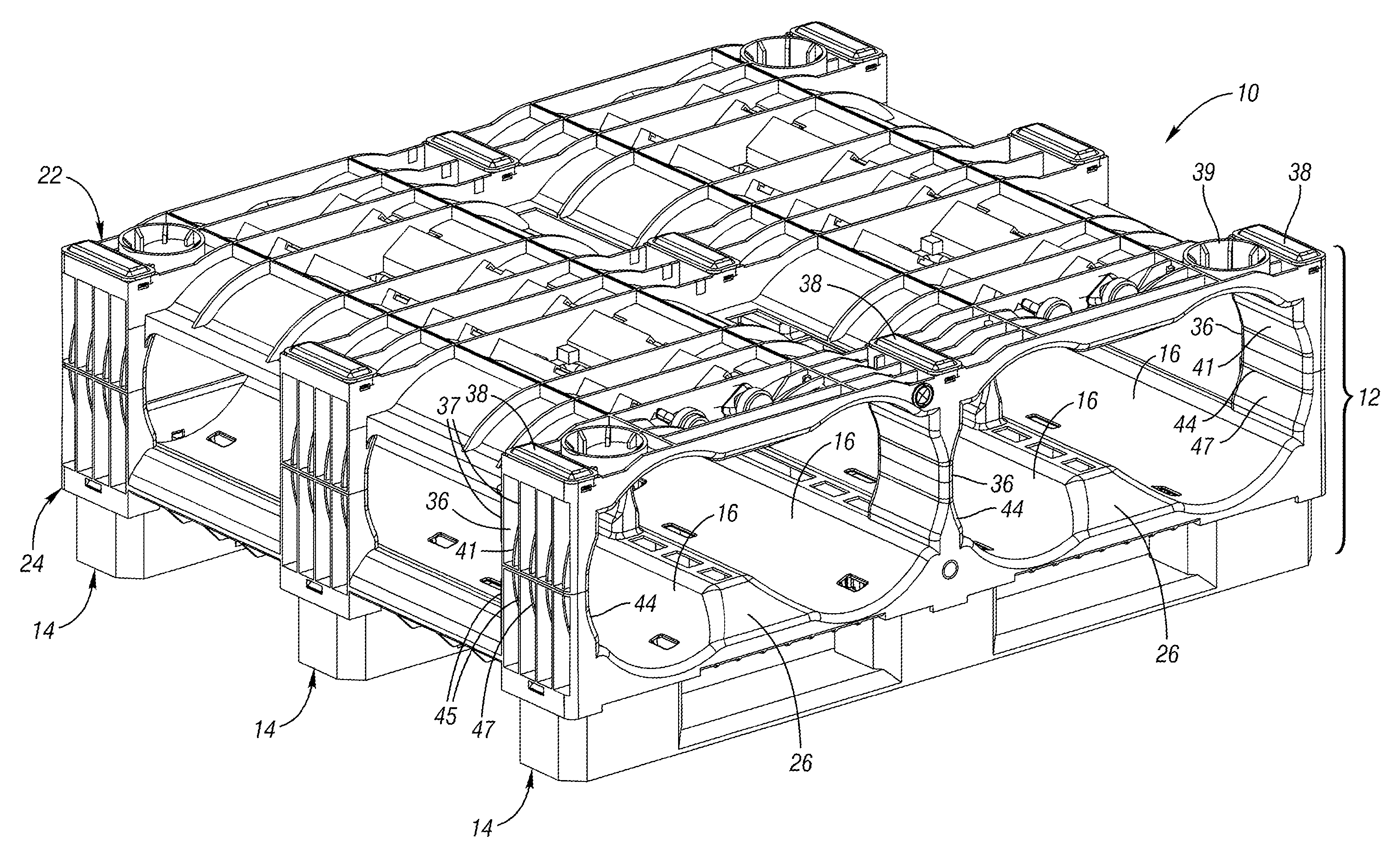

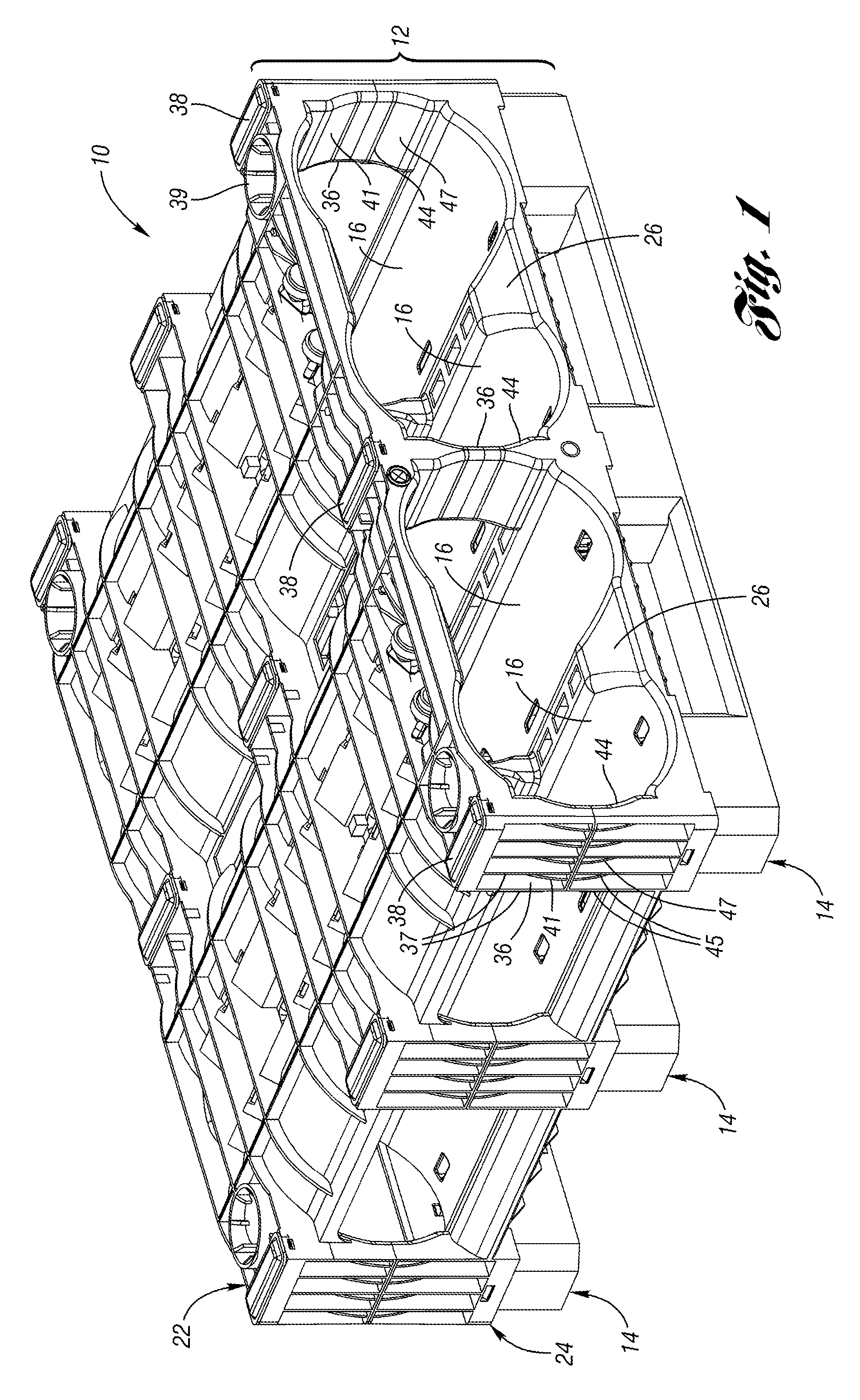

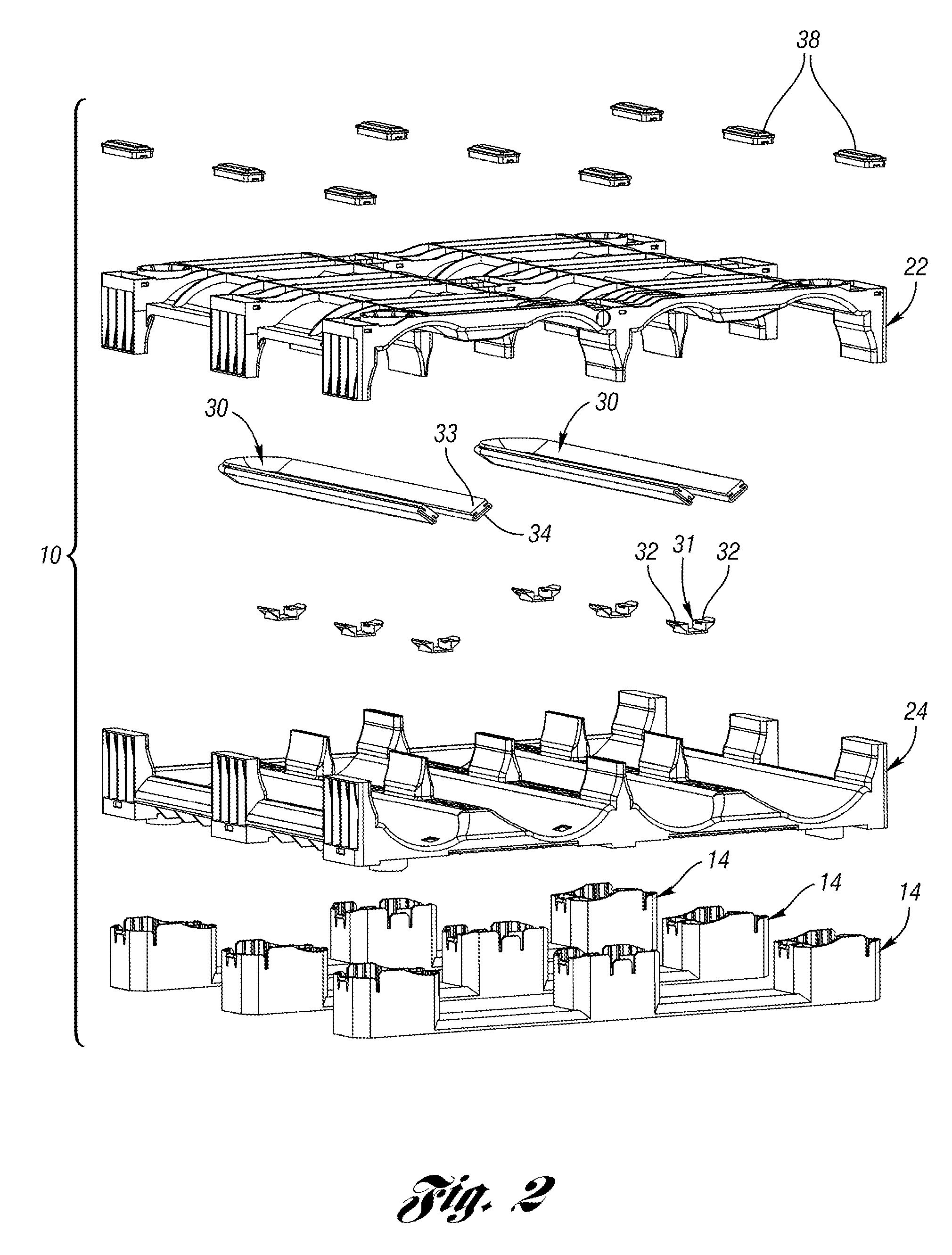

Rack for containers

InactiveUS20080083683A1Improve stabilityEasy to stackBottle cupboardsBottle transportationEngineeringSupport surface

Owner:REHRIG PACIFIC CO INC

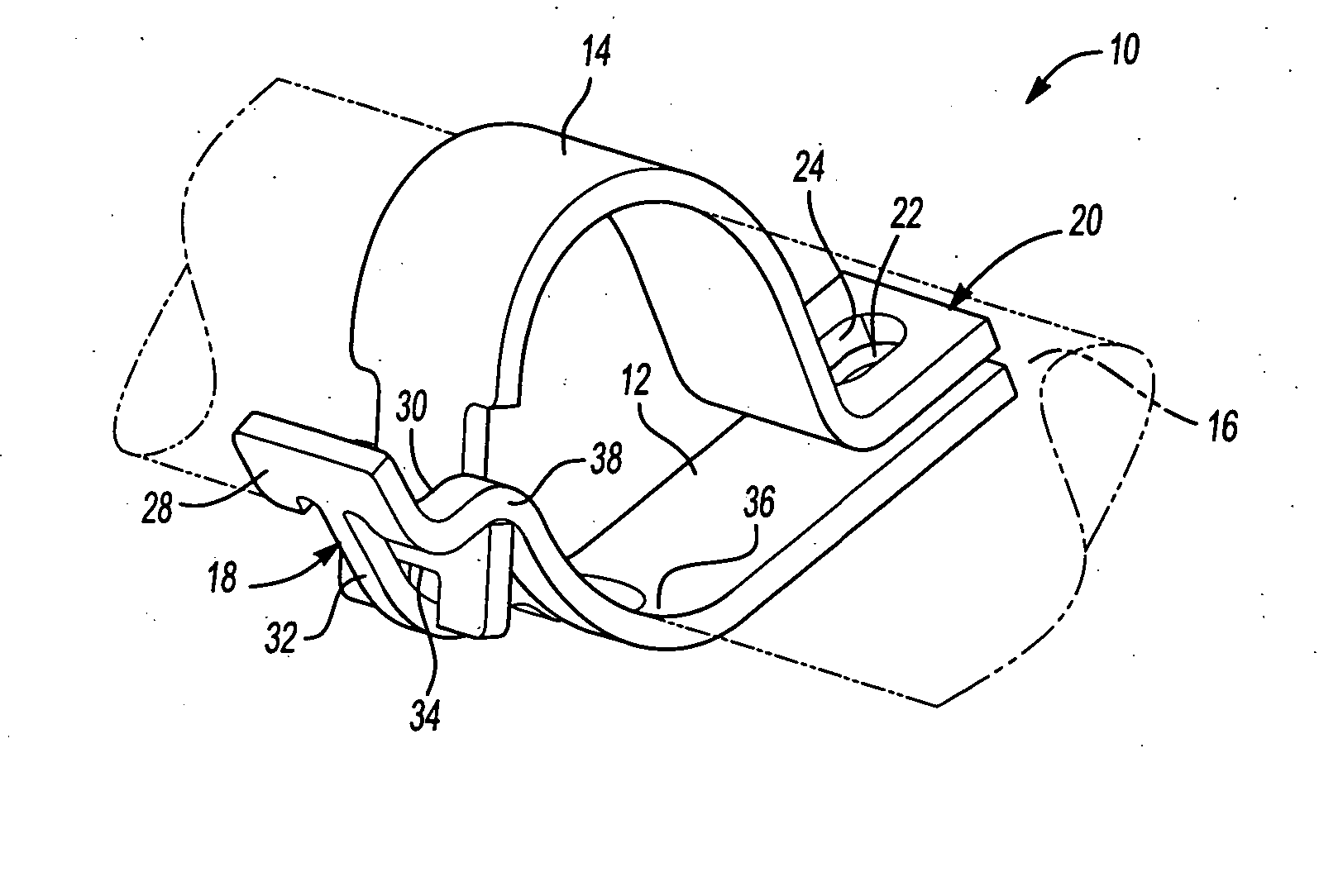

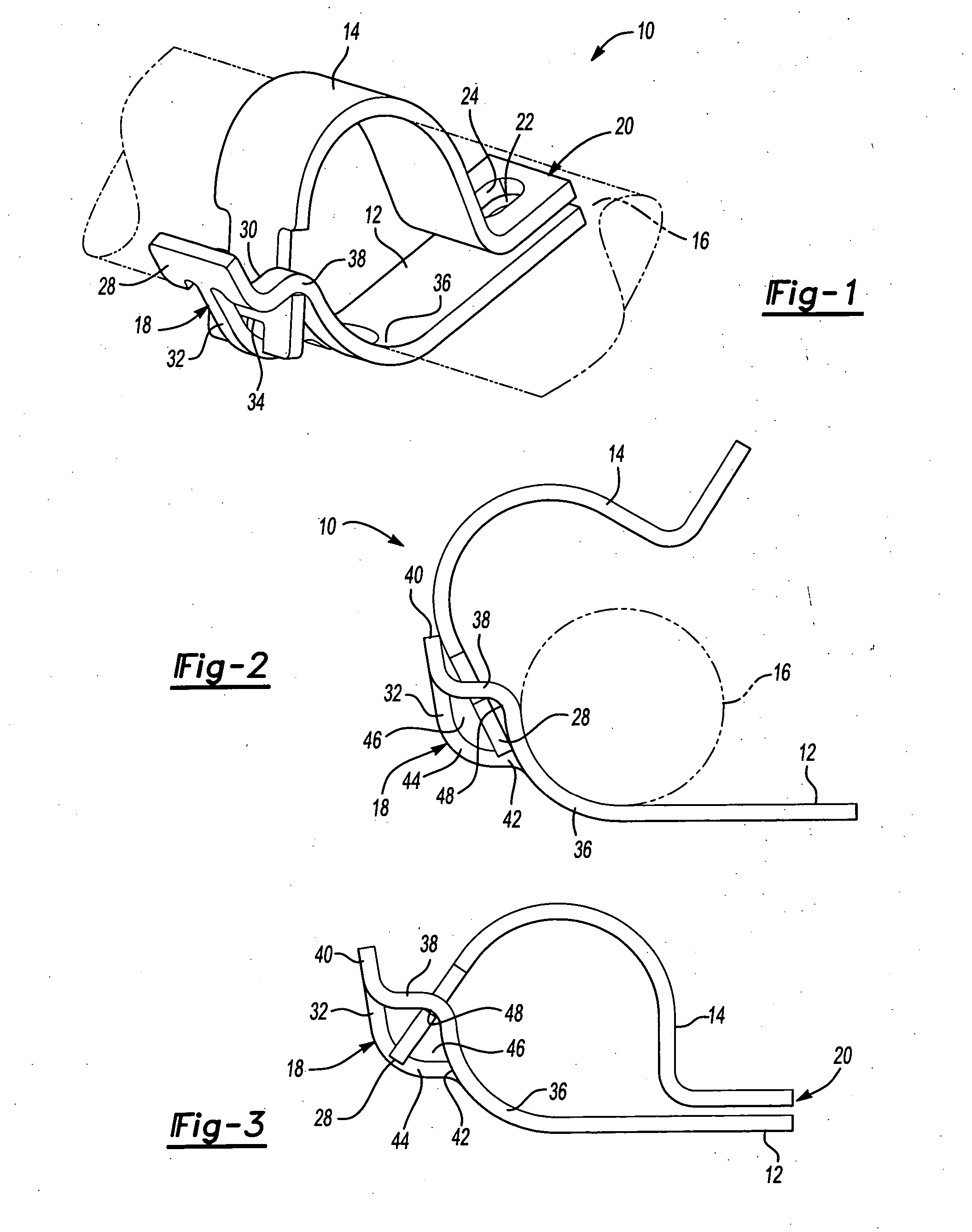

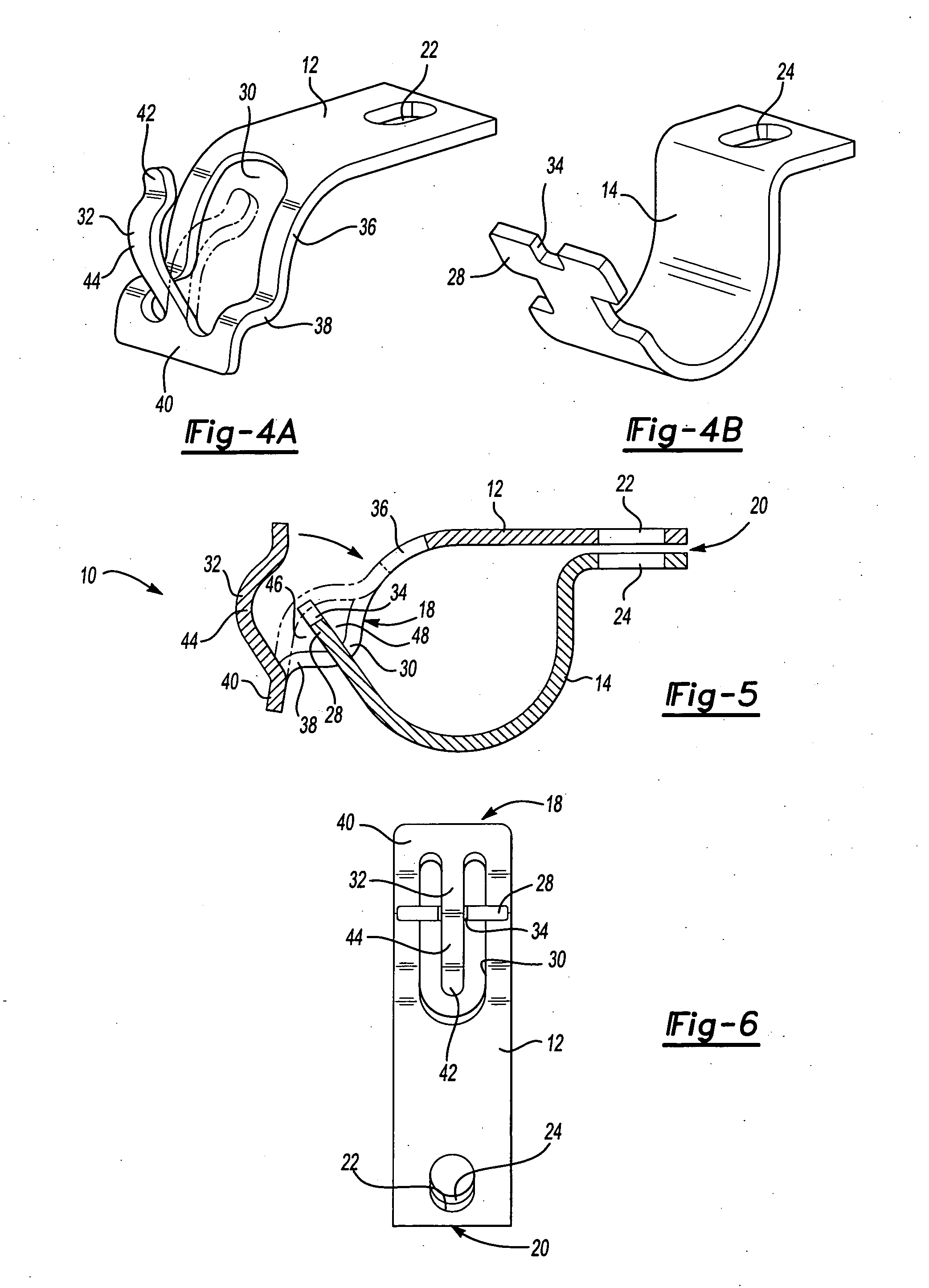

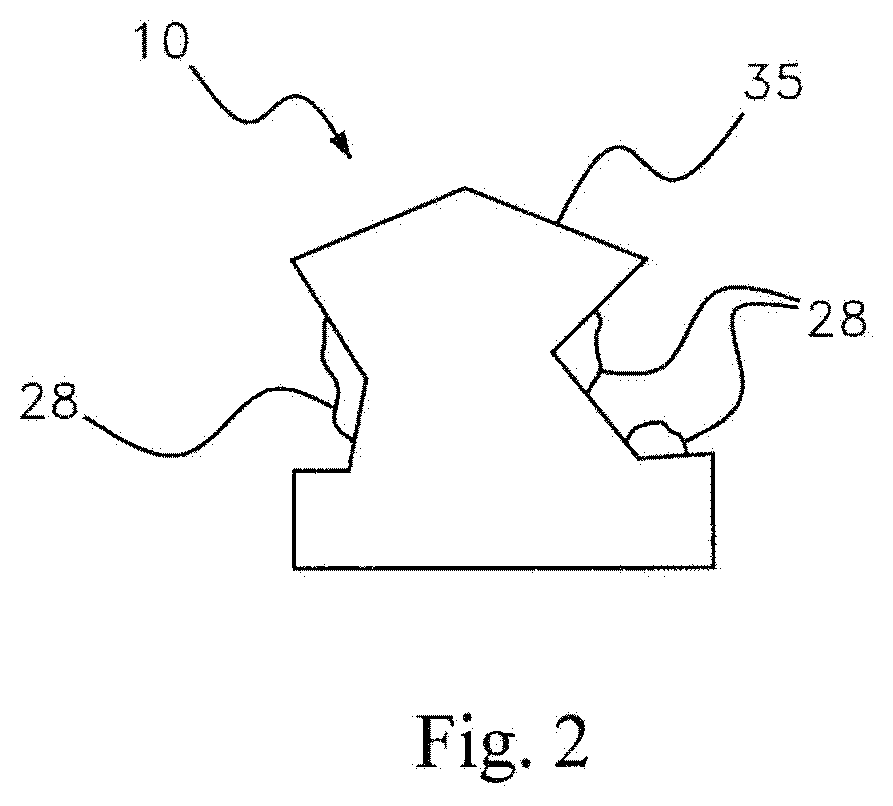

Interlocked two-part clamp

ActiveUS20060213039A1Avoid disassemblySnap fastenersPipe supportsBiomedical engineeringSupport surface

Owner:FRANKLIN FASTENER

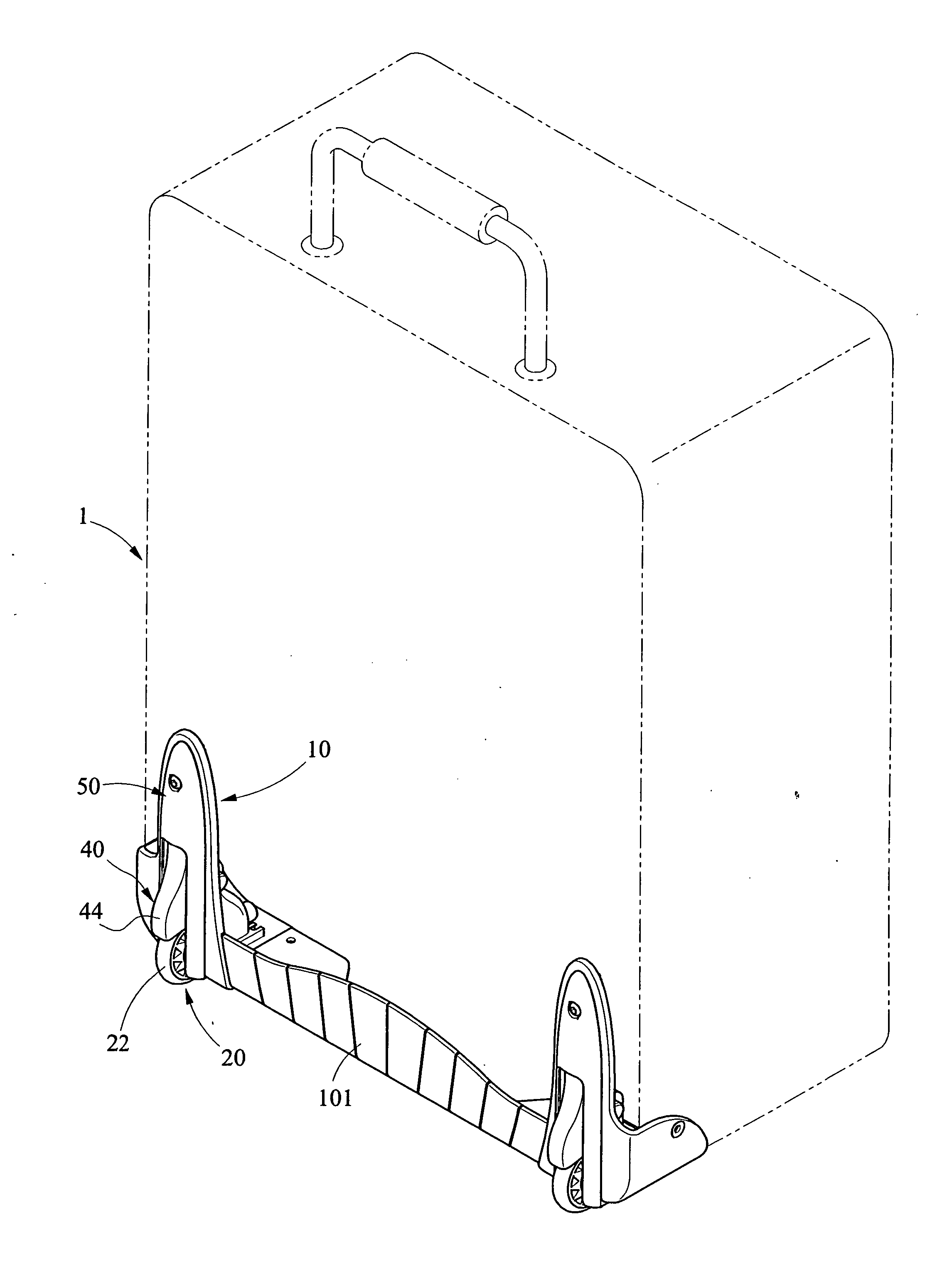

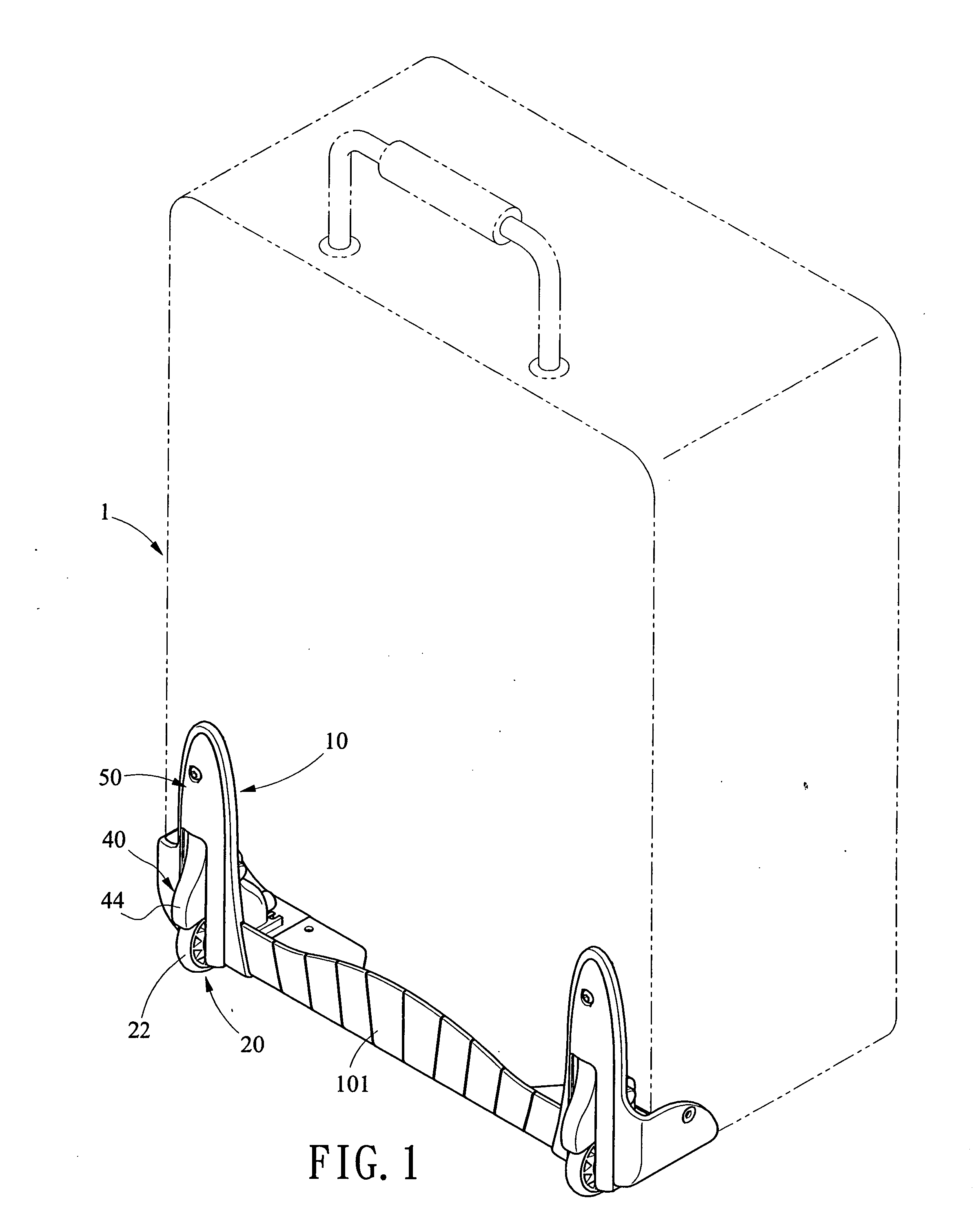

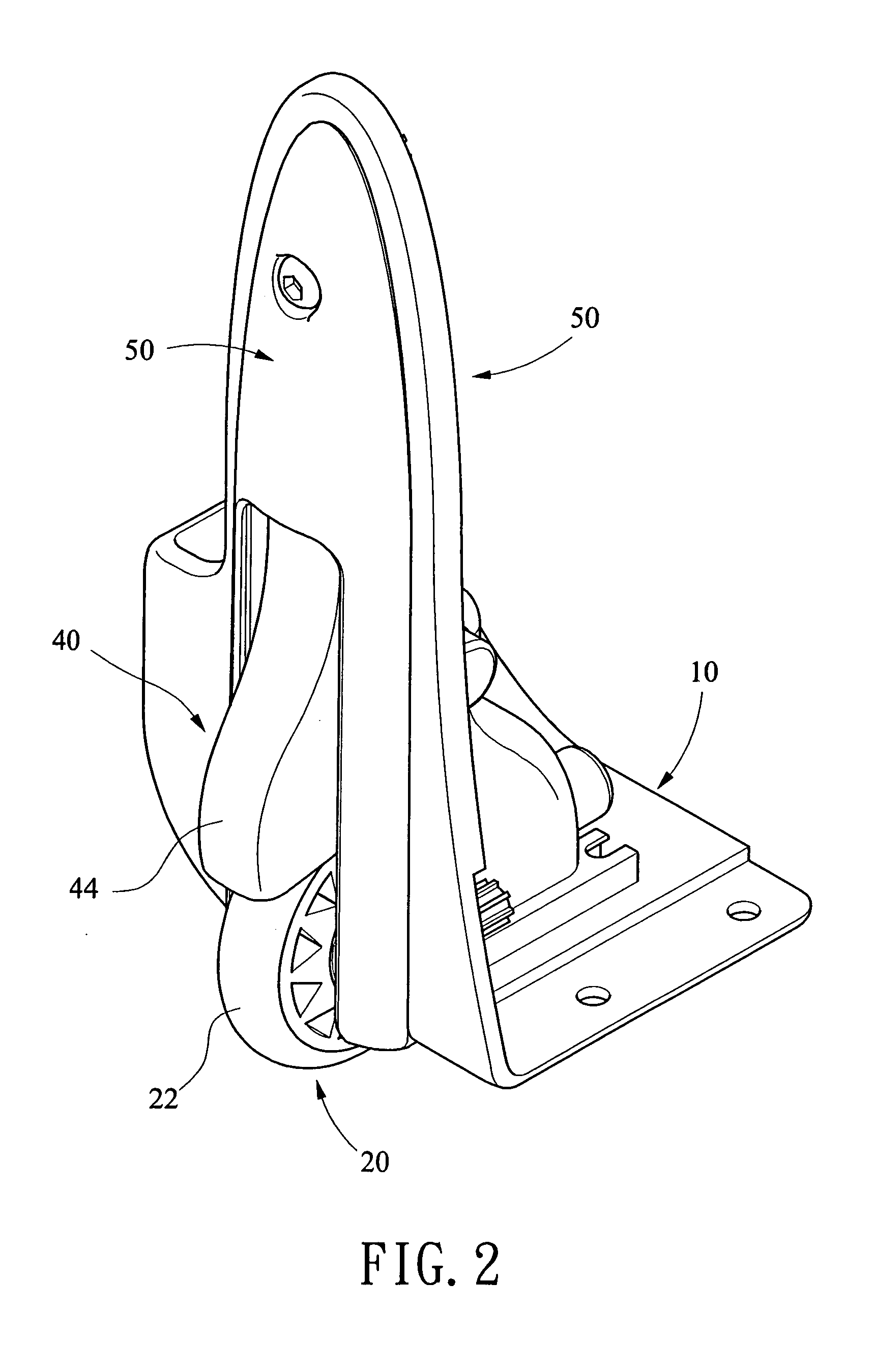

Luggage wheel system

Owner:SHER MOU ONG

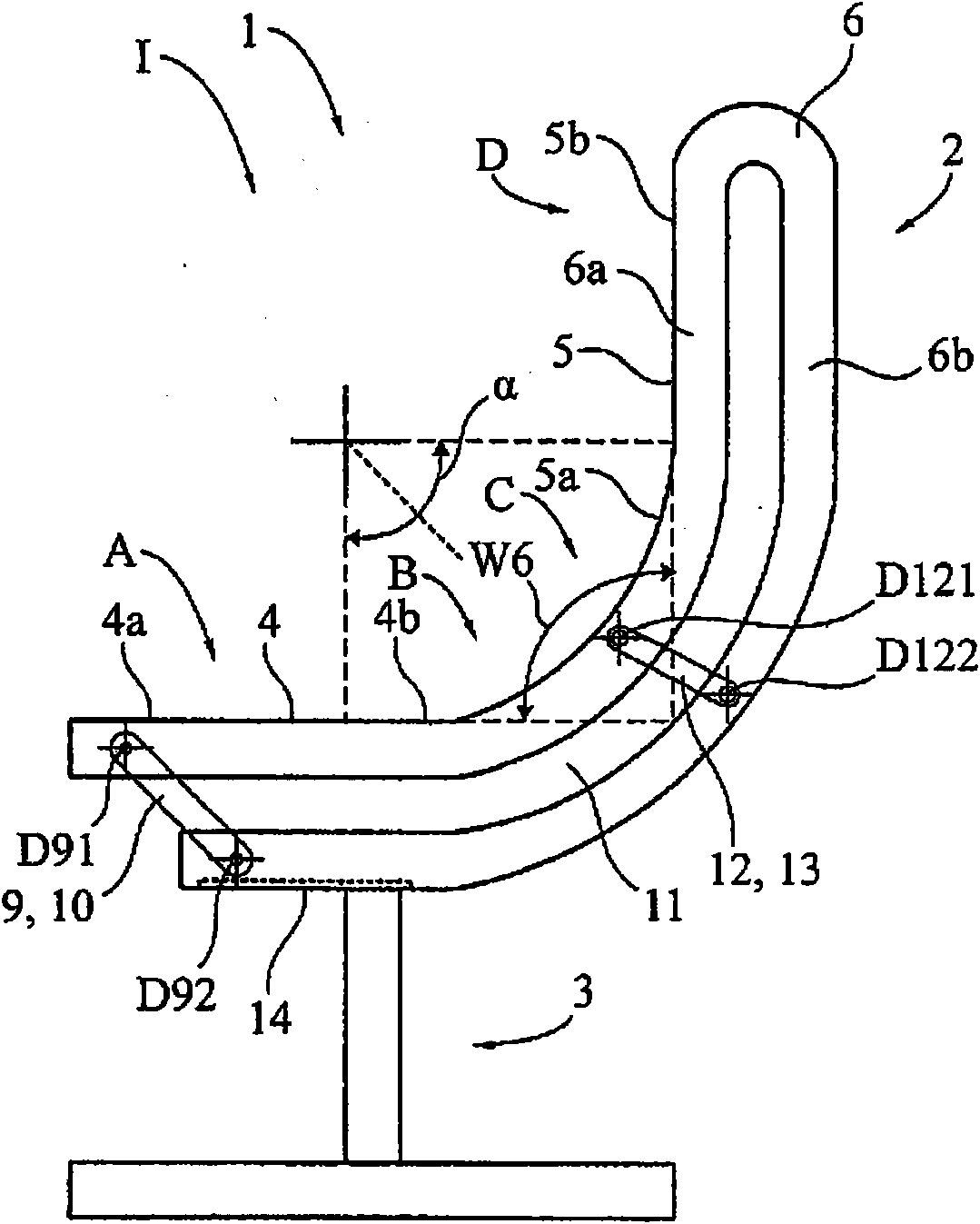

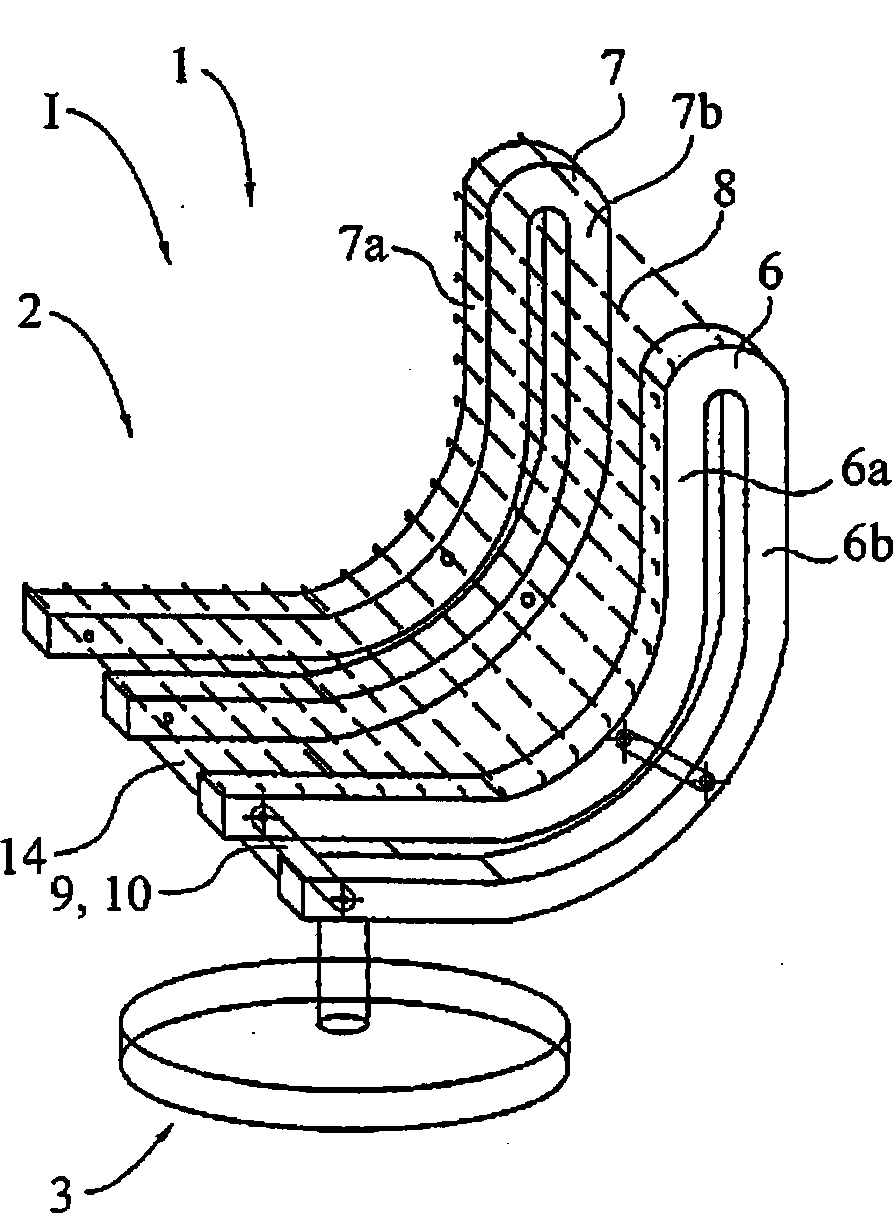

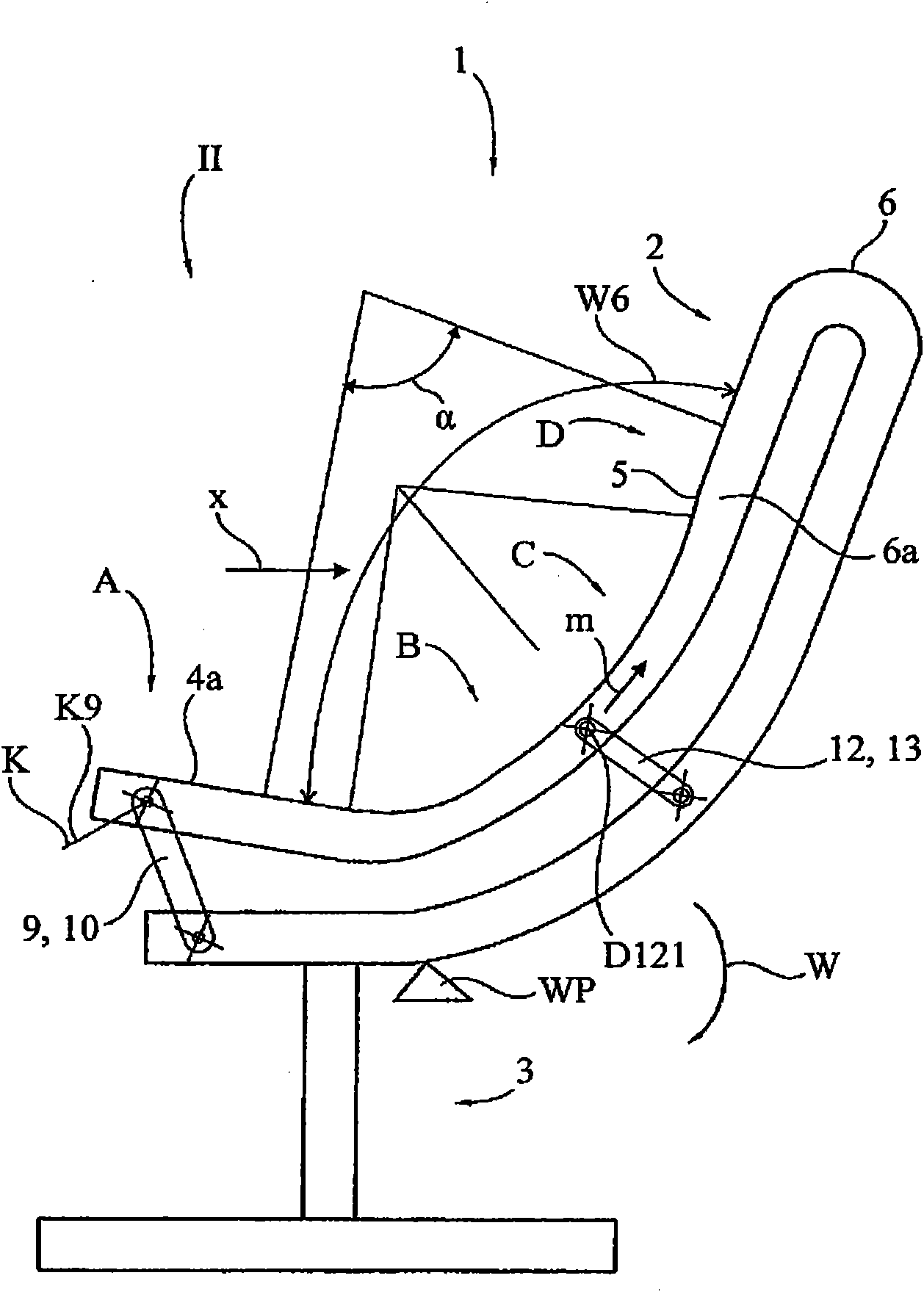

Leg rest for a stroller

InactiveUS20080217981A1Overcomes or mitigates one orReduce decreaseCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringSupport surface

A removable leg rest for a stroller having a chassis made of chassis members. The removable leg rest comprises a support structure, at least one fastening mechanism and at least one angle adjusting mechanism. The support structure has a leg support surface. The fastening mechanism is attached to the support structure and is operative to fix the support structure to the chassis. The angle adjusting mechanism is used to set an angle of the support structure with respect to the chassis members.

Owner:TON THAT QUOC THANH

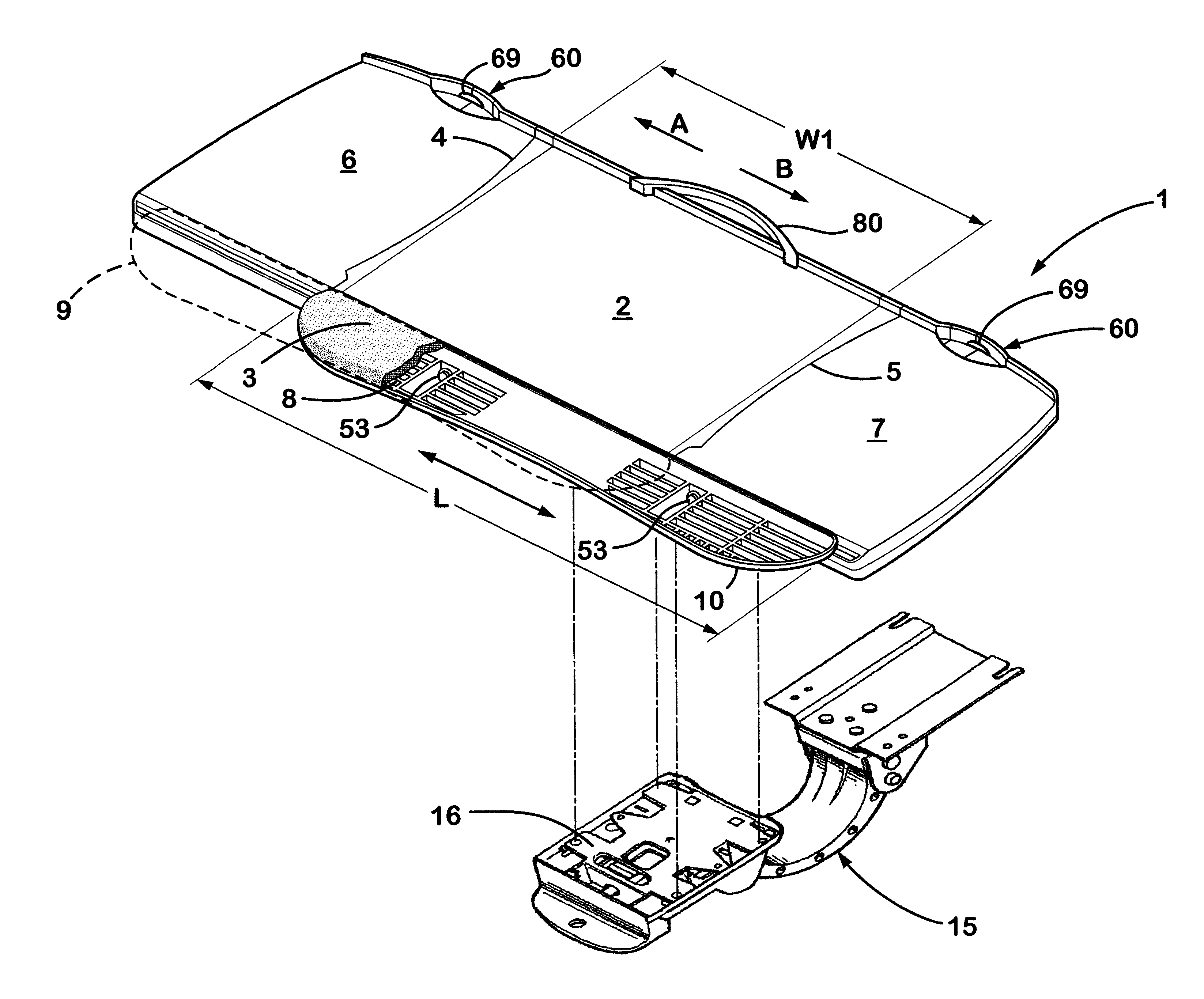

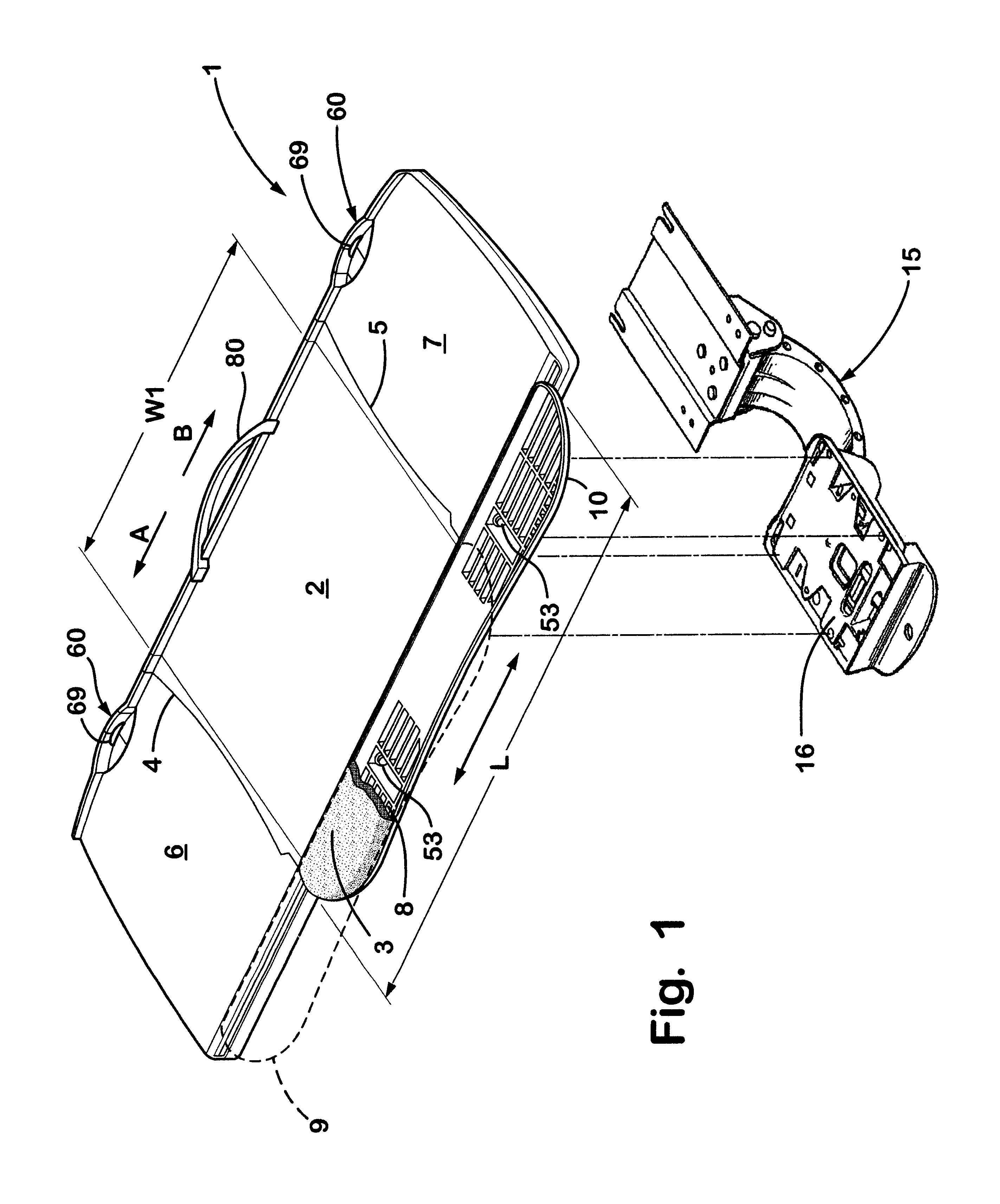

Keyboard support

InactiveUS6874736B1Prevent movementOffice tablesCurtain suspension devicesFront edgeSupport surface

Owner:STEELCASE DEV INC

Load support structure

Owner:HERMAN MILLER INC

Turbine Vane Securing Mechanism

InactiveUS20090053056A1Eliminate relative motionPrevent movementEngine manufacturePump componentsTurbine bladeBearing surface

Owner:SIEMENS ENERGY INC

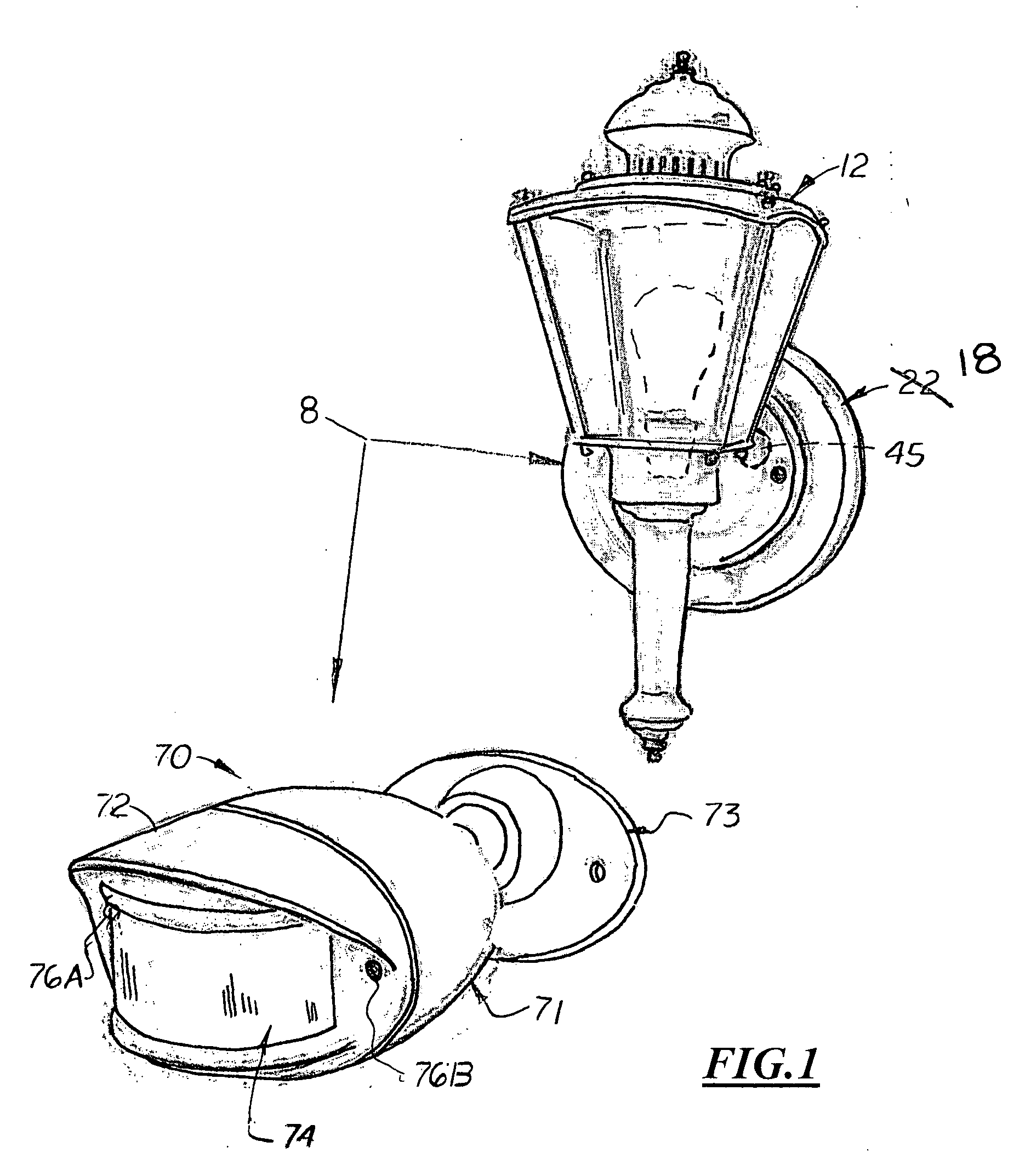

Wireless motion activated light fixture base plate and kit

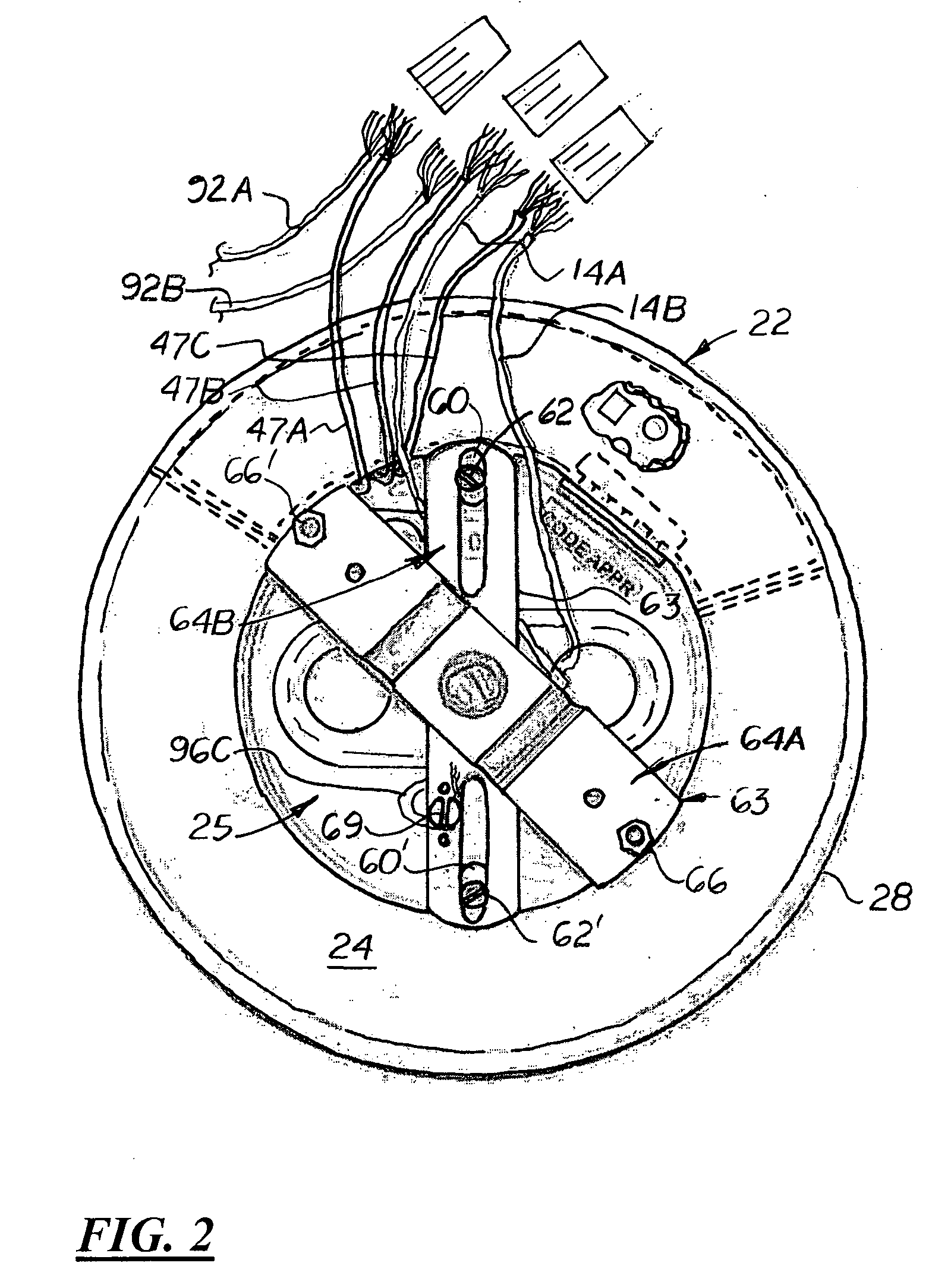

Owner:COLEMAN CABLE INC

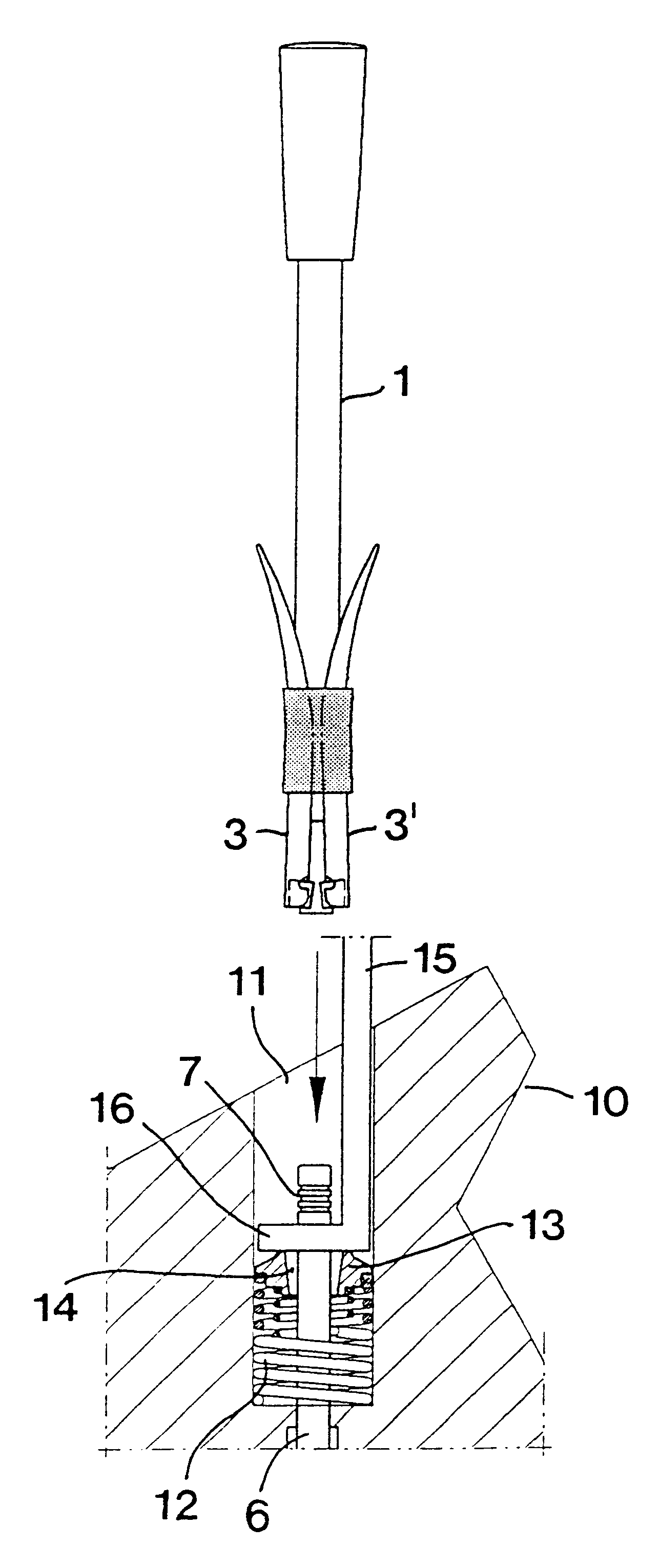

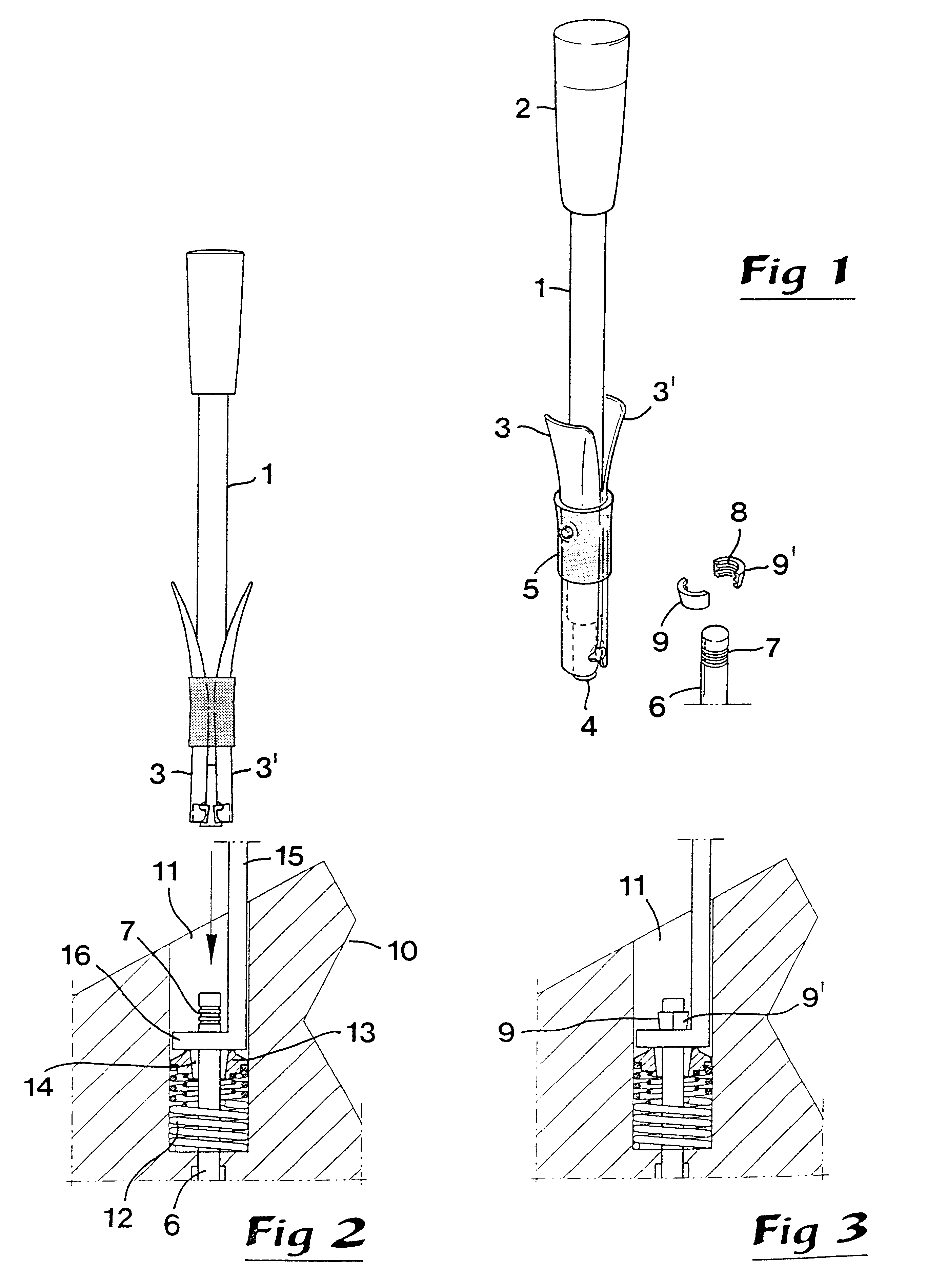

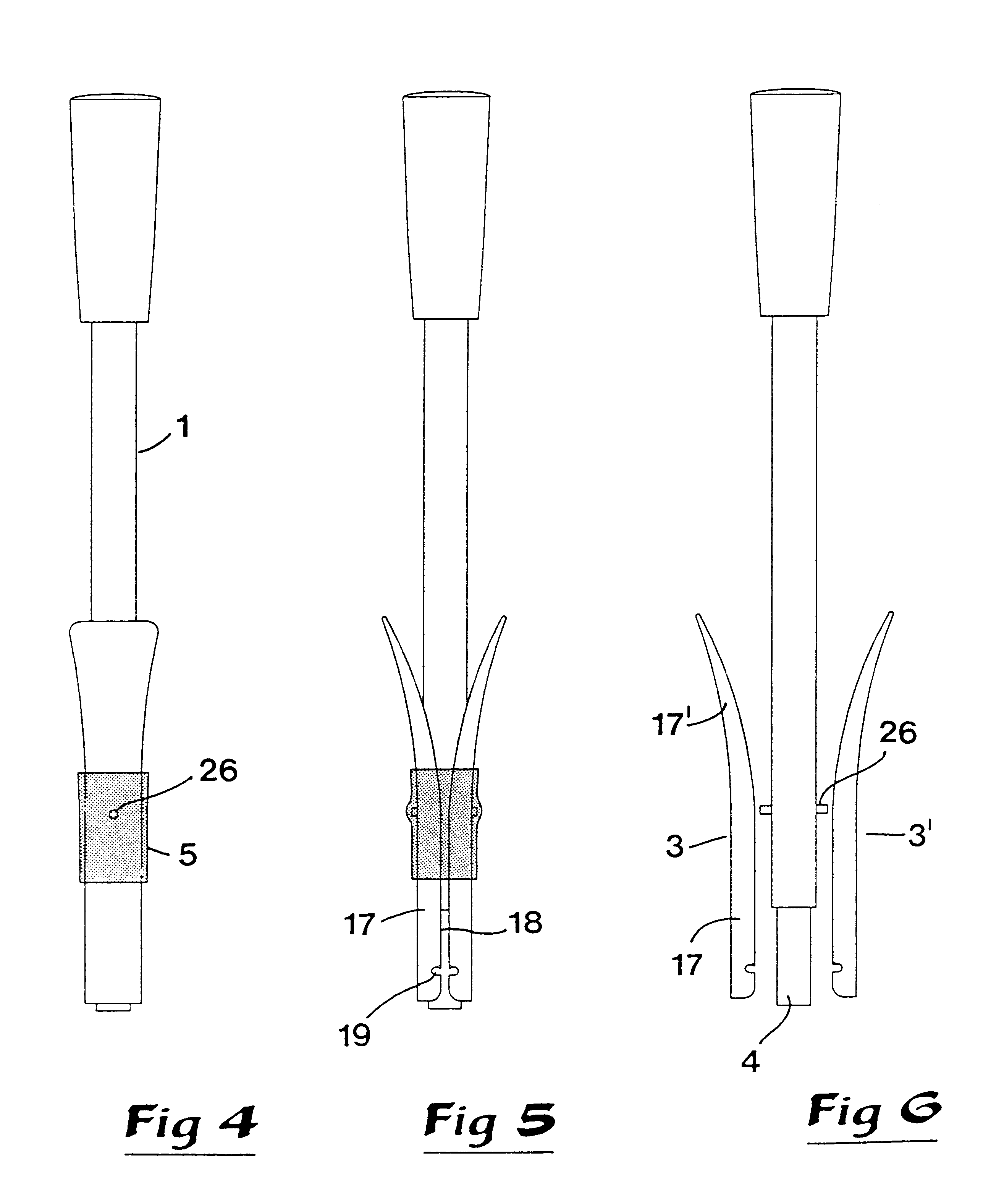

Tool for mounting disk valves in motor cylinder heads

Owner:TREGO MASKIN

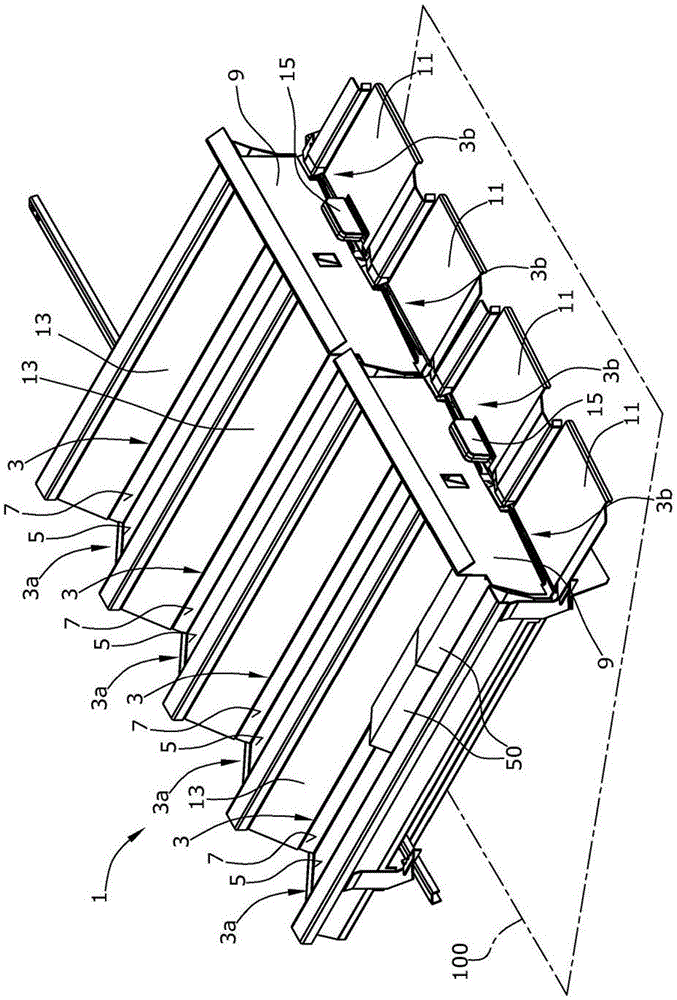

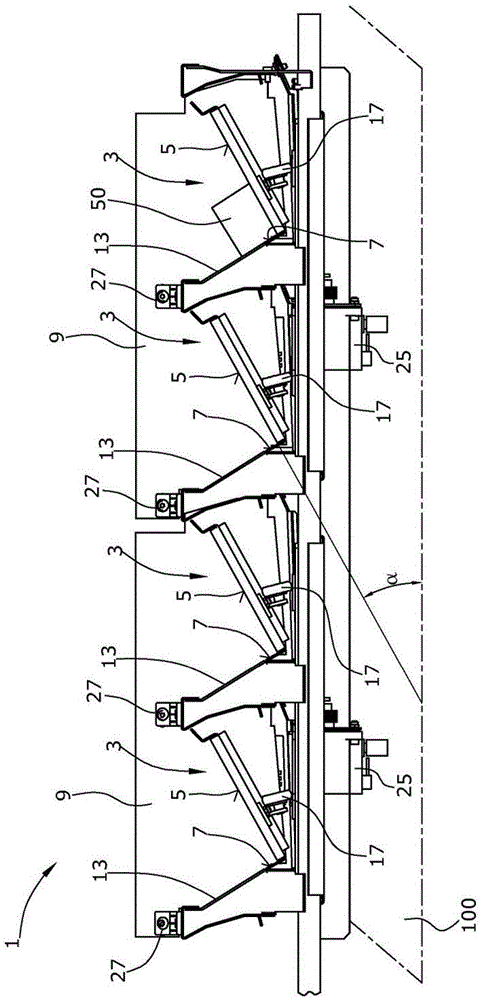

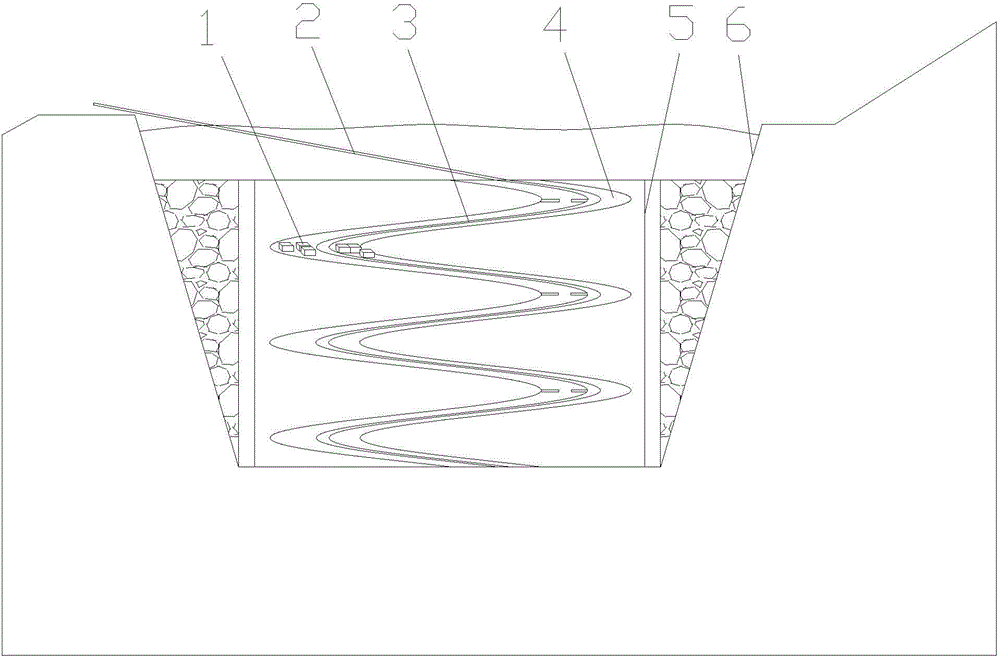

Rollgang for flat quenches for glass tempering

InactiveCN104724920AEliminates down deflectionImprove qualityGlass transportation apparatusGlass tempering apparatusToughened glassPlain bearing

The invention discloses a rollgang for flat quenches for glass tempering, which comprises a rack and multiple conveying rolls, wherein the multiple conveying rolls are parallelly arranged on the rack at certain interval, at least one conveying roll is composed of two sections of rollers, a middle rollgang supporting device is also provided, the middle rollgang supporting device comprises a mounting seat, a mounting frame, a support rod and a sliding bearing pedestal, the mounting frame is connected with the mounting seat, one end of the support rod is fixedly connected with the mounting frame, the other end of the support rod is fixedly connected with the sliding bearing pedestal, a sliding bearing is arranged in the sliding bearing pedestal, the two ends of the sliding bearing are respectively provided with a plane bearing, a connecting head is respectively arranged in inner holes of the sliding bearing and the plane bearings, the two ends of the connecting heads are respectively connected with the two sections of rollers constituting a same conveying roll, and the top end of the sliding bearing pedestal is not higher than the rotary supporting surface of the conveying roll. By using the rollgang disclosed by the invention, the down-warping of the middle part of the rollgang can be eliminated, thereby improving the quality of tempered glass.

Owner:LUOYANG NORTHGLASS TECH +1

Composite connection type hydraulic knife handle

ActiveCN108907776AHigh strengthPrevent extravasationPositioning apparatusMetal-working holdersConnection typeInterference fit

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:CHENGDU CHENGLIN CNC TOOL CO LTD

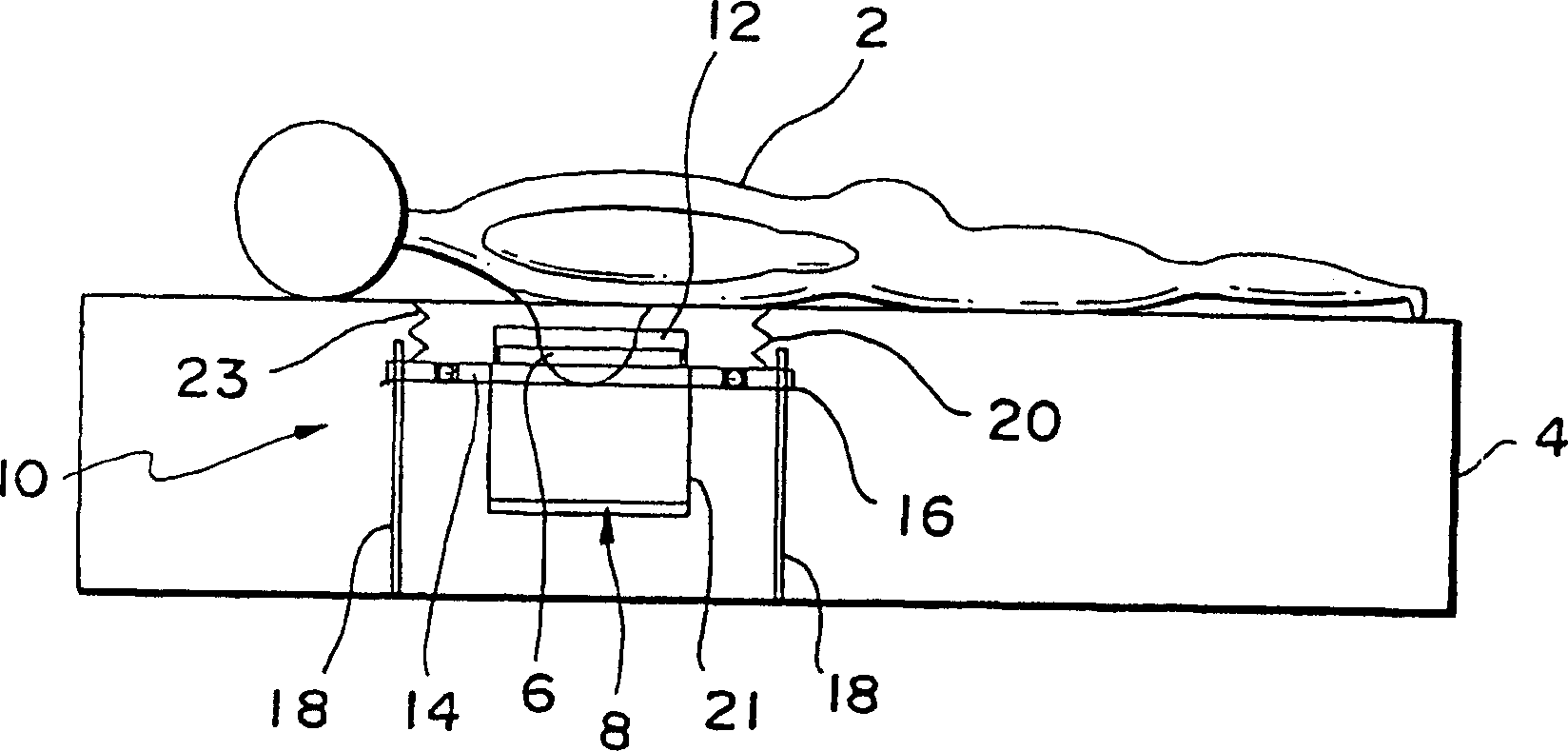

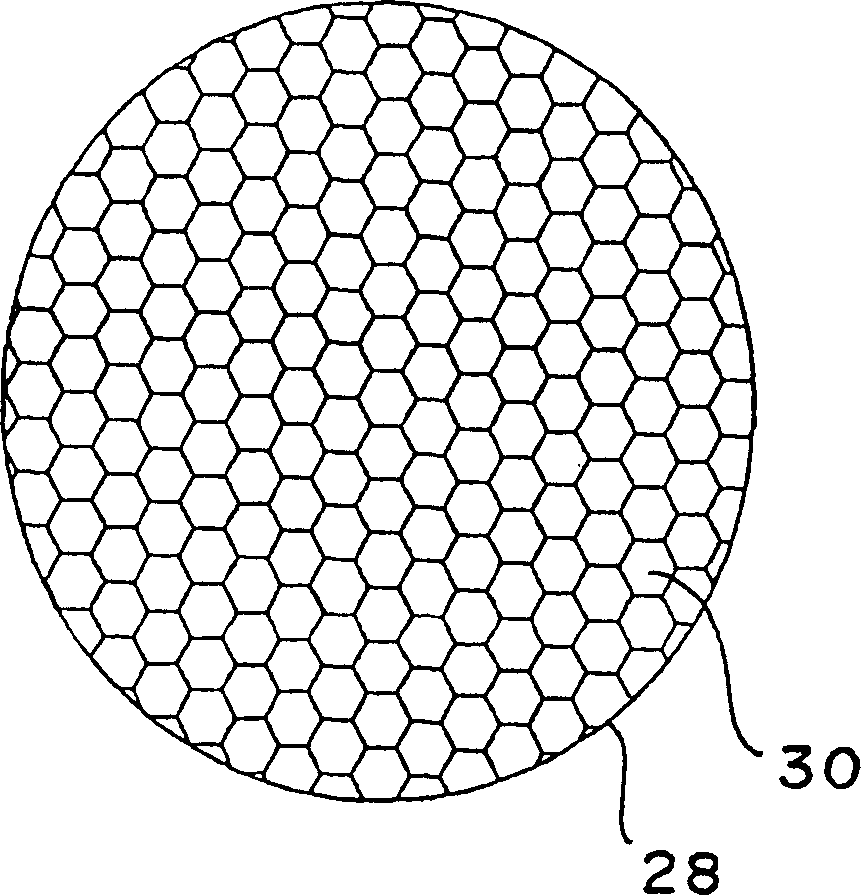

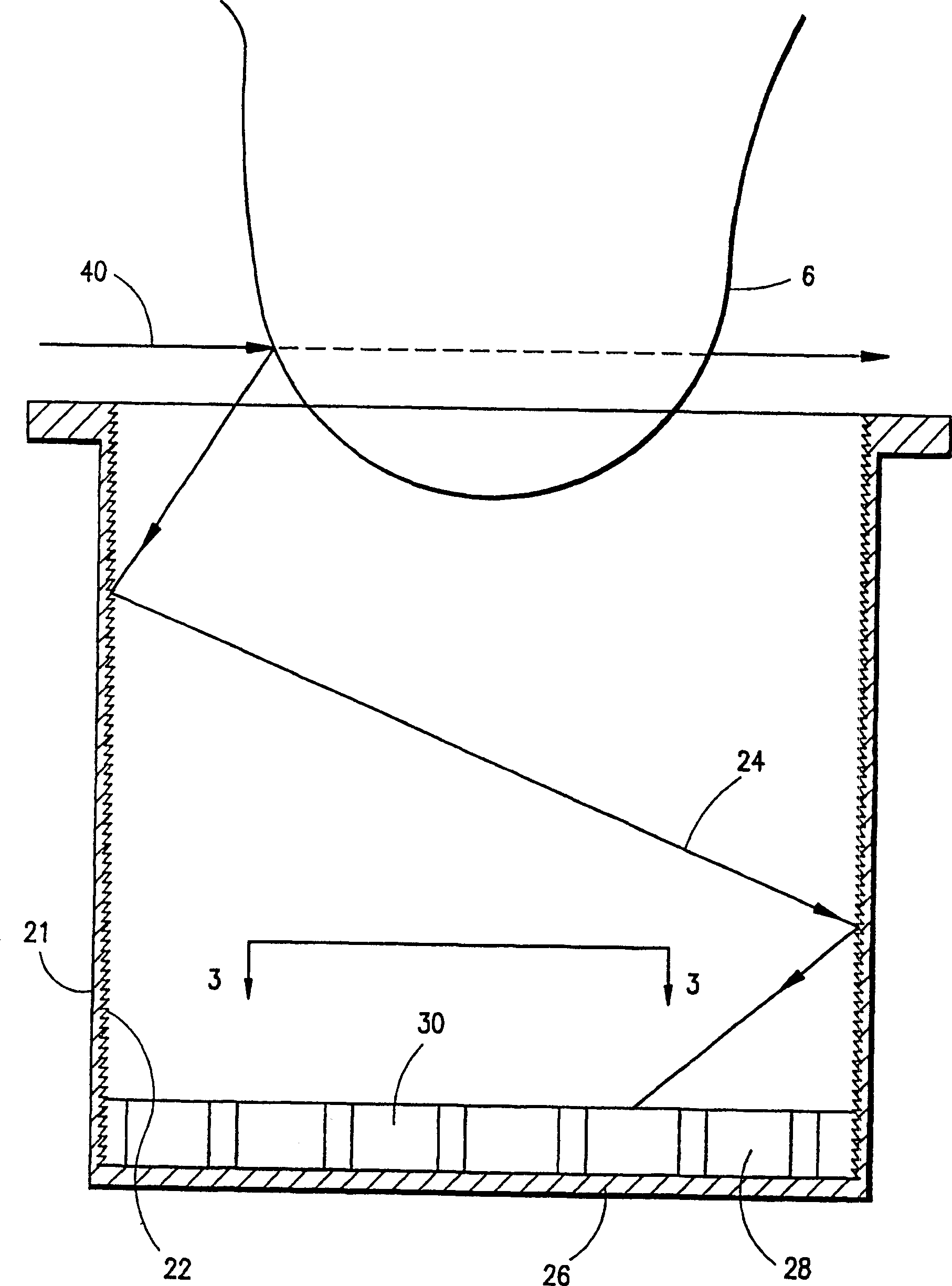

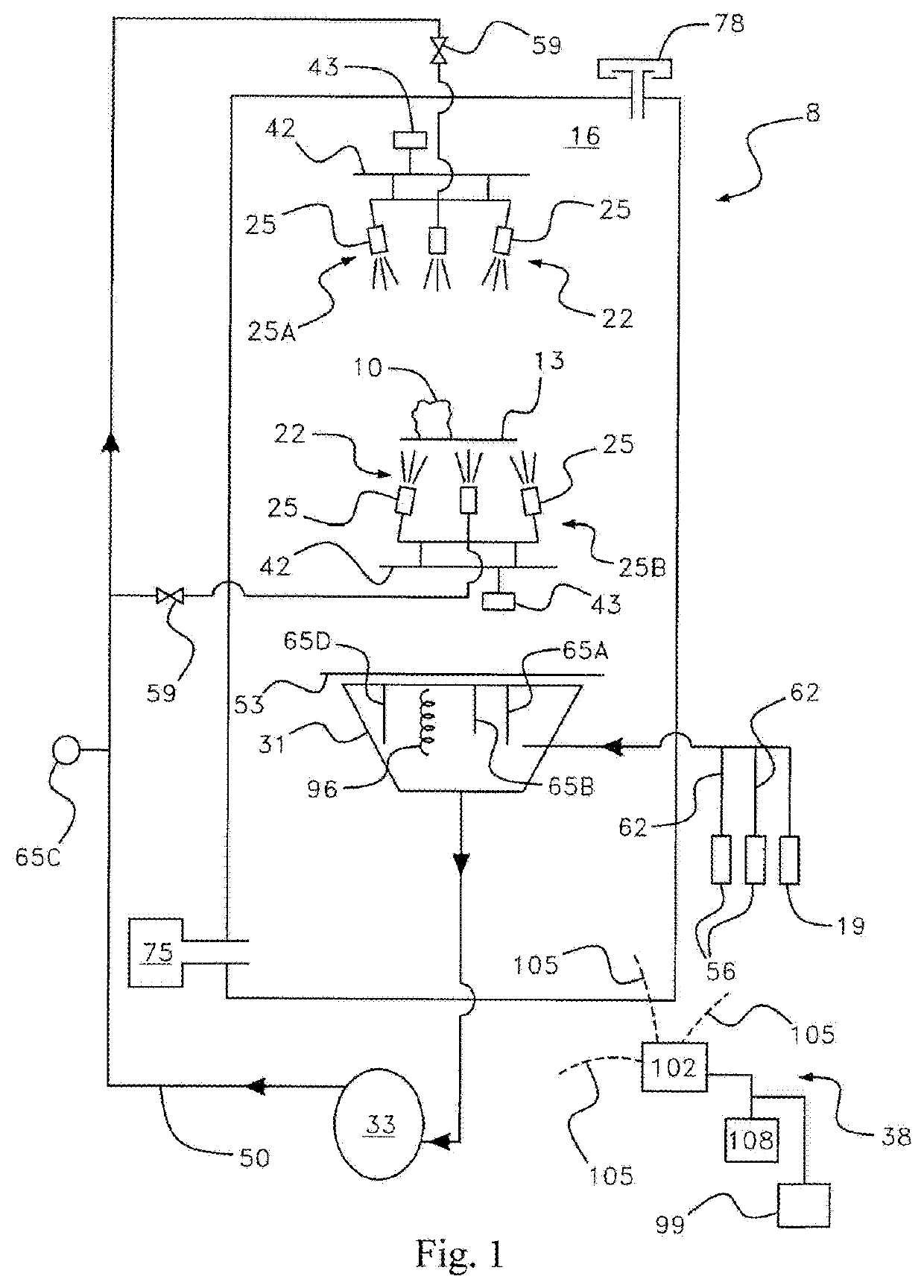

Scanner for medical optical imaging device employing suppression of optical reflections

Owner:IMAGING DIAGNOSTIC SYST

Rotary cutting device

ActiveUS8100040B2Small radial extentReliable cuttingStock shearing machinesMetal working apparatusHard metalSupport surface

The invention relates to a rotary cutting device comprising a rotatable cutting tool and a rotatable anvil roller incorporating a cutting support, wherein a cutting edge, which co-operates with the cutting support, is arranged on the cutting tool for cutting a web of material, and wherein at least one support ring with a support surface is mounted on the cutting tool for supporting the cutting tool relative to the anvil roller. In order to develop the rotary cutting device in such a way as to enable high-tensile materials also to be cut in a reliable and precise manner, it is proposed, in accordance with the invention, that the cutting edge and the cutting support be made of a hard metal at least in the surface regions thereof, and in that the cutting edge be set back relative to the support surface in a radial direction, wherein the radial spacing between the cutting edge and the support surface is formed in dependence on the modulus of elasticity of the support ring in such a manner that the cutting edge virtually touches the cutting support when a bias force is applied.

Owner:AICHELE WERKZEUGE

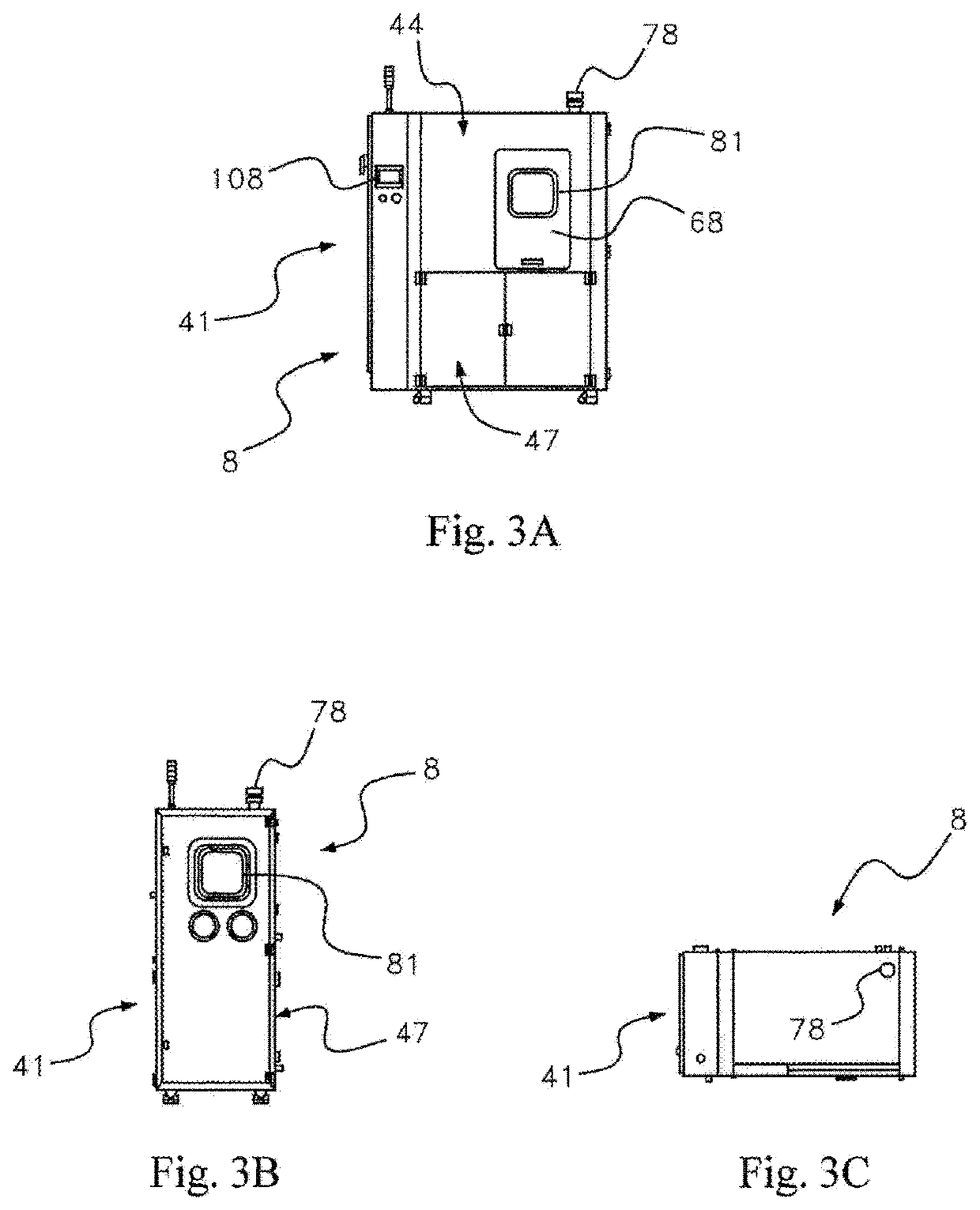

Method And Apparatus For Support Removal Using Directed Atomized And Semi-Atomized Fluid

ActiveUS20210008808A1Additive manufacturing apparatusIncreasing energy efficiencyInterior spaceSupport removal

Owner:POSTPROCESS TECH INC

Cabinet with hidden swing-out bottom platform

InactiveUS20160081470A1Improved shelf accessibilitySmooth maintenanceFurniture partsVariable dimension cabinetsEngineeringActuator

A cabinet mounted to a surface above a counter includes an outer housing with a front door and an open bottom and at least one support panel connected to a support surface above the counter, at least one side panel internally disposed within the housing and movably connected thereto by a displacement actuator to permit to downward movement of the side panel through the open bottom toward the counter and upward movement of the side panel for disposal within the housing, and a bottom shelf movably connected to the at least one side panel by an extendable and retractable actuator for moving the bottom shelf outward when the side panel is in a downwardly disposed position and for moving said bottom shelf inward for storage when the side panel is in a upwardly disposed position such that the bottom shelf and the side panel are housed within the housing.

Owner:LEMON KELLY D

Goods transfer device, and warehouse with goods transfer device

Owner:GEBR WILLACH

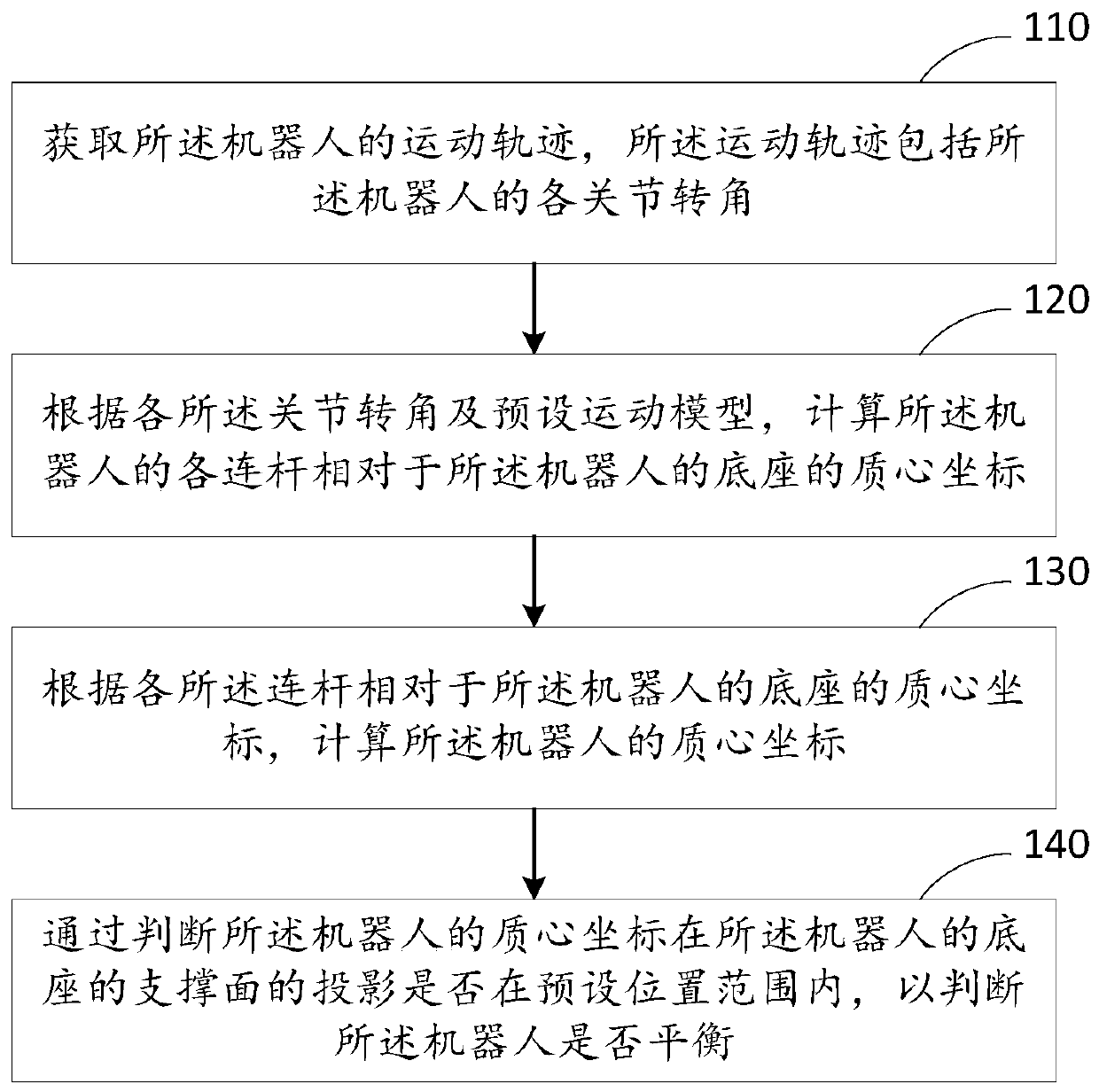

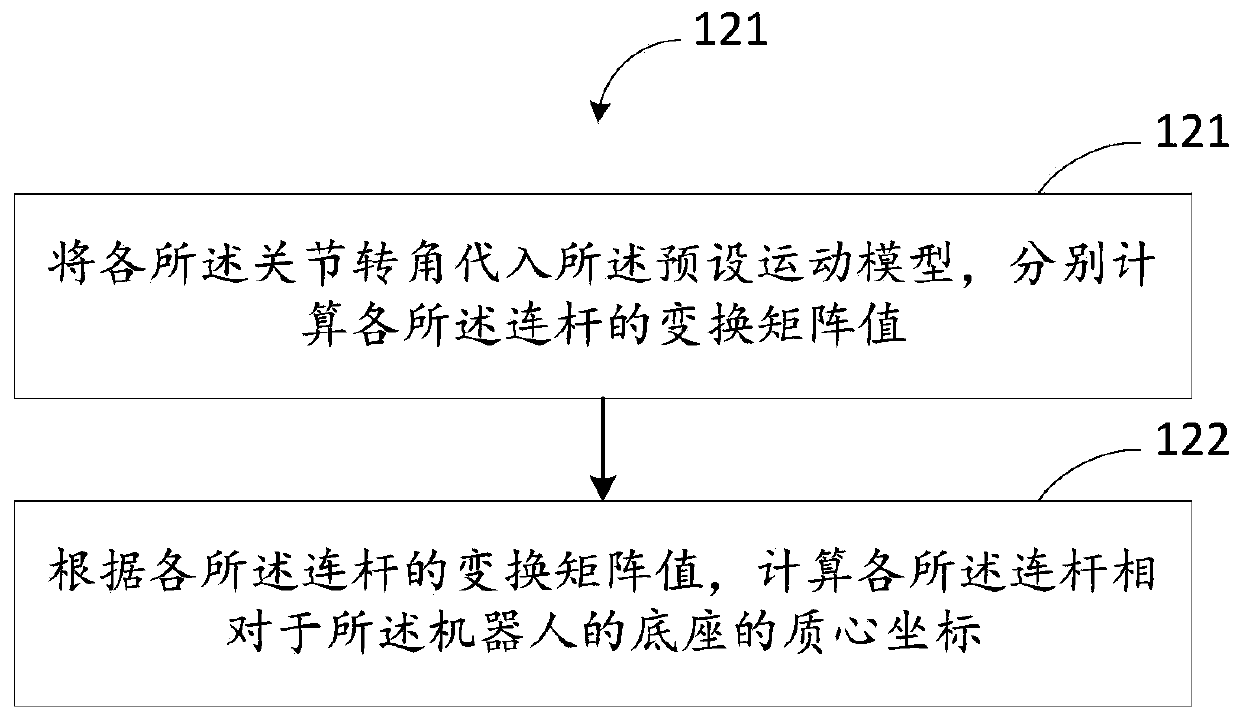

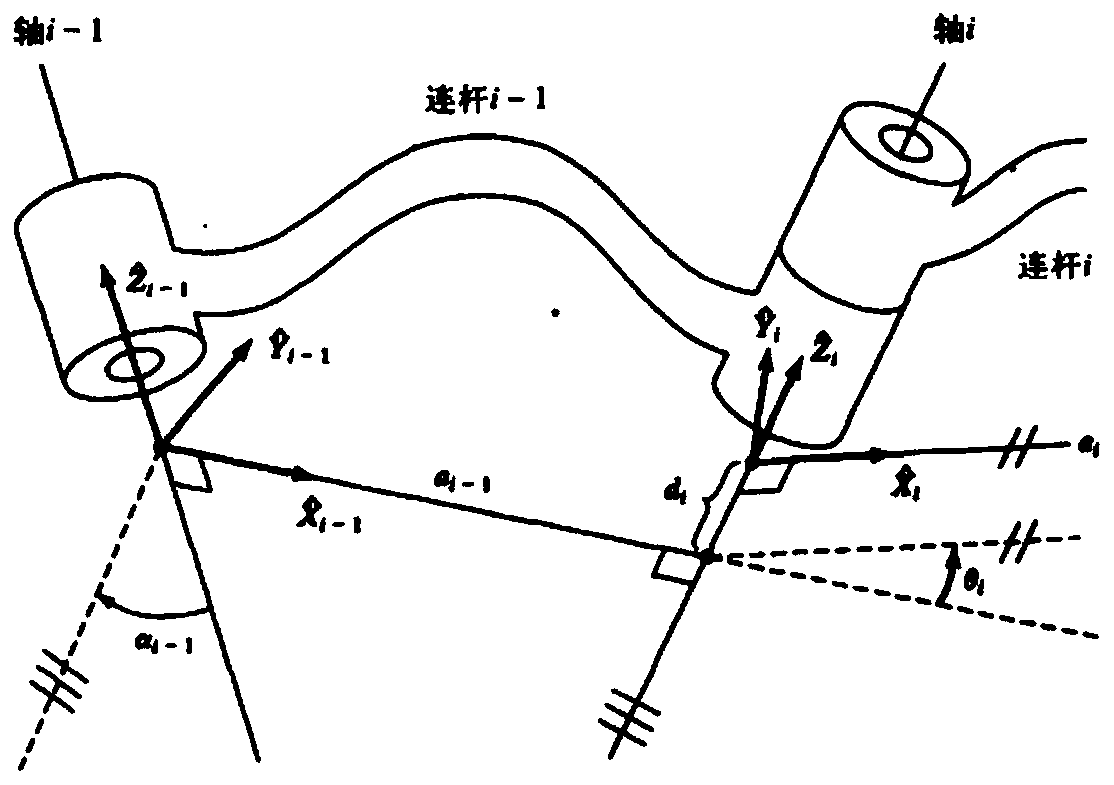

Robot balance detection method, device, equipment and robot

Owner:CLOUDMINDS BEIJING TECH CO LTD

Wheat-steeping groove hanging device

Owner:YANGZHOU XIANYE GRP

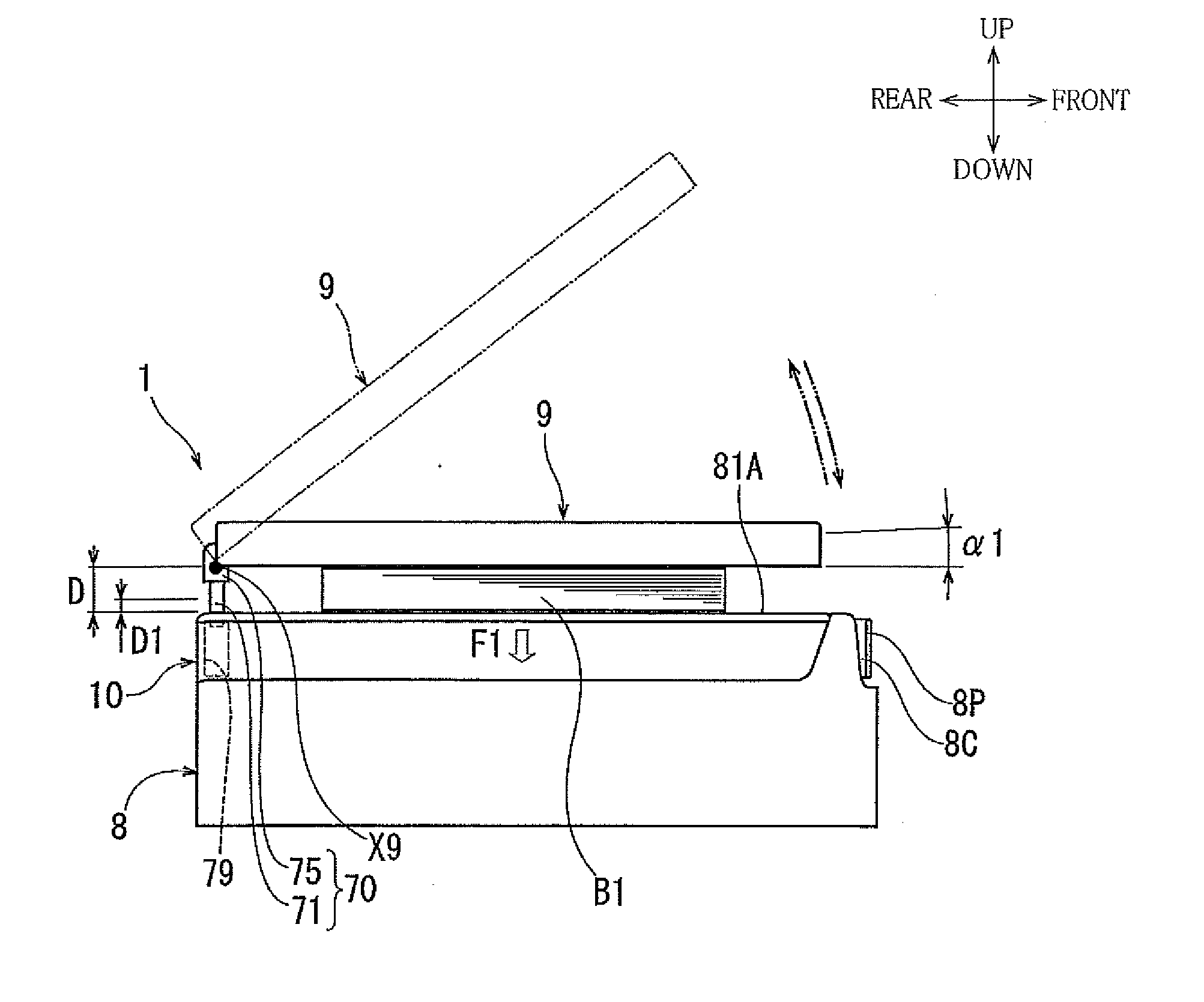

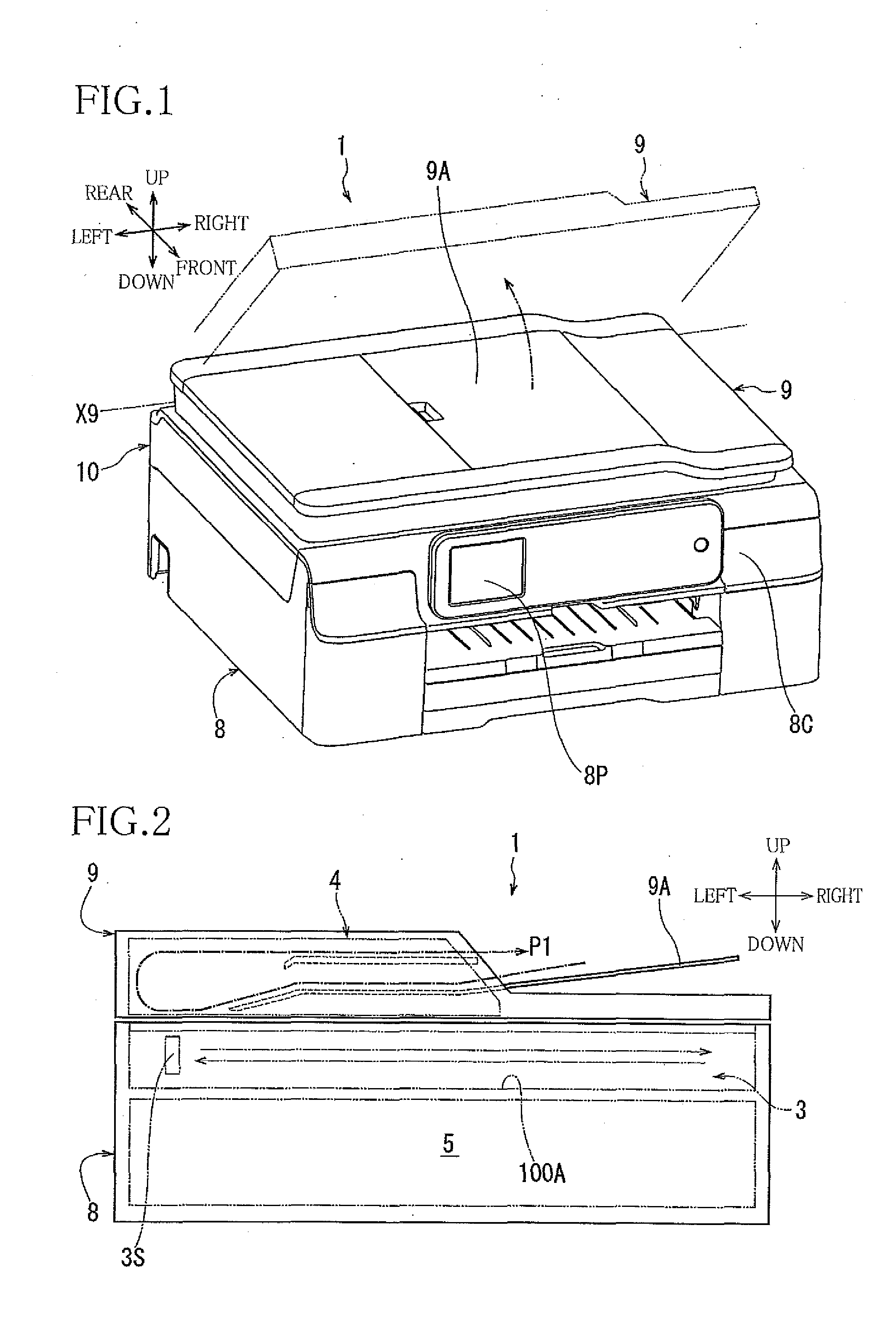

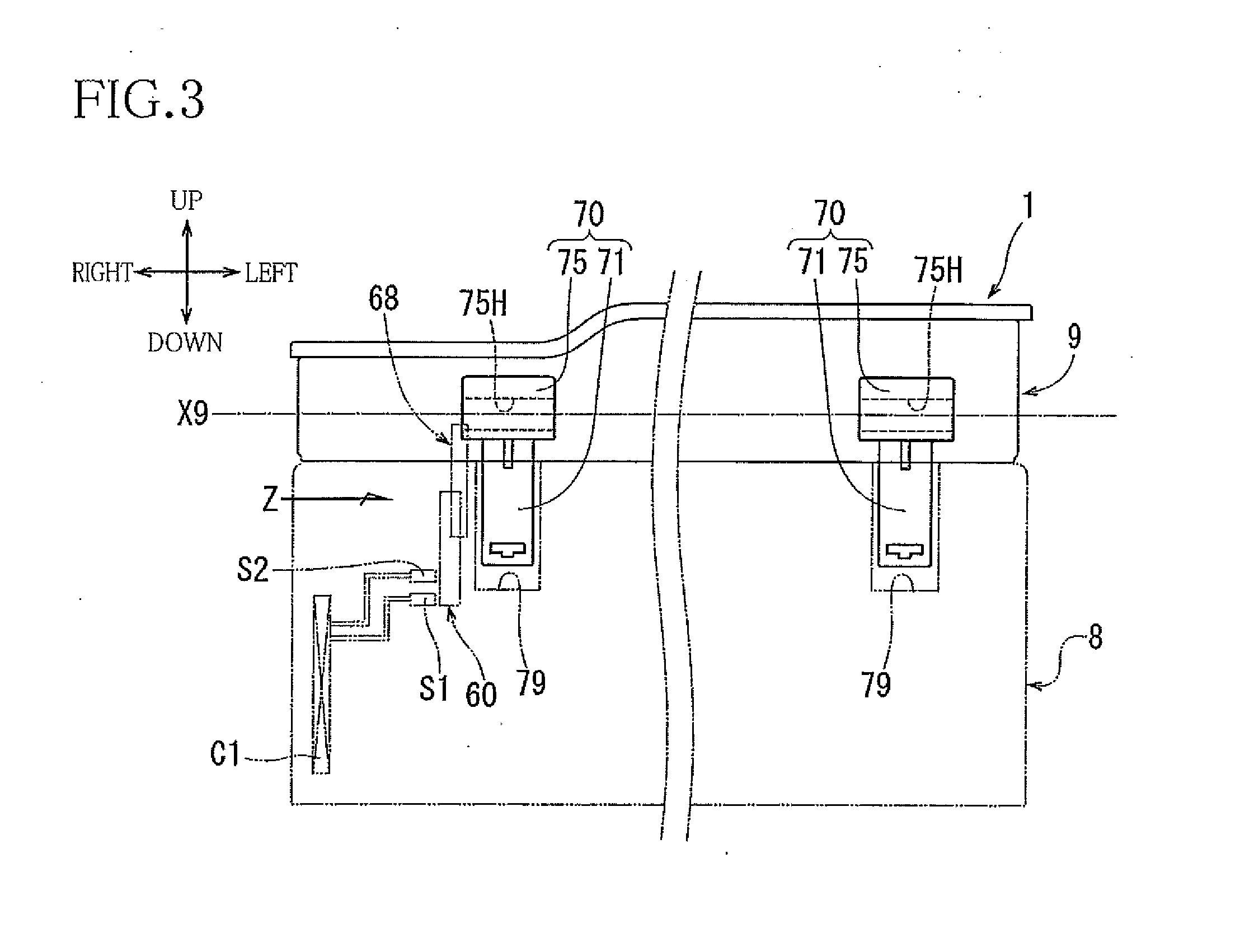

Image Reading Apparatus

ActiveUS20160212286A1Digitally marking record carriersVisual representation by matrix printersEngineeringSupport surface

Owner:BROTHER KOGYO KK

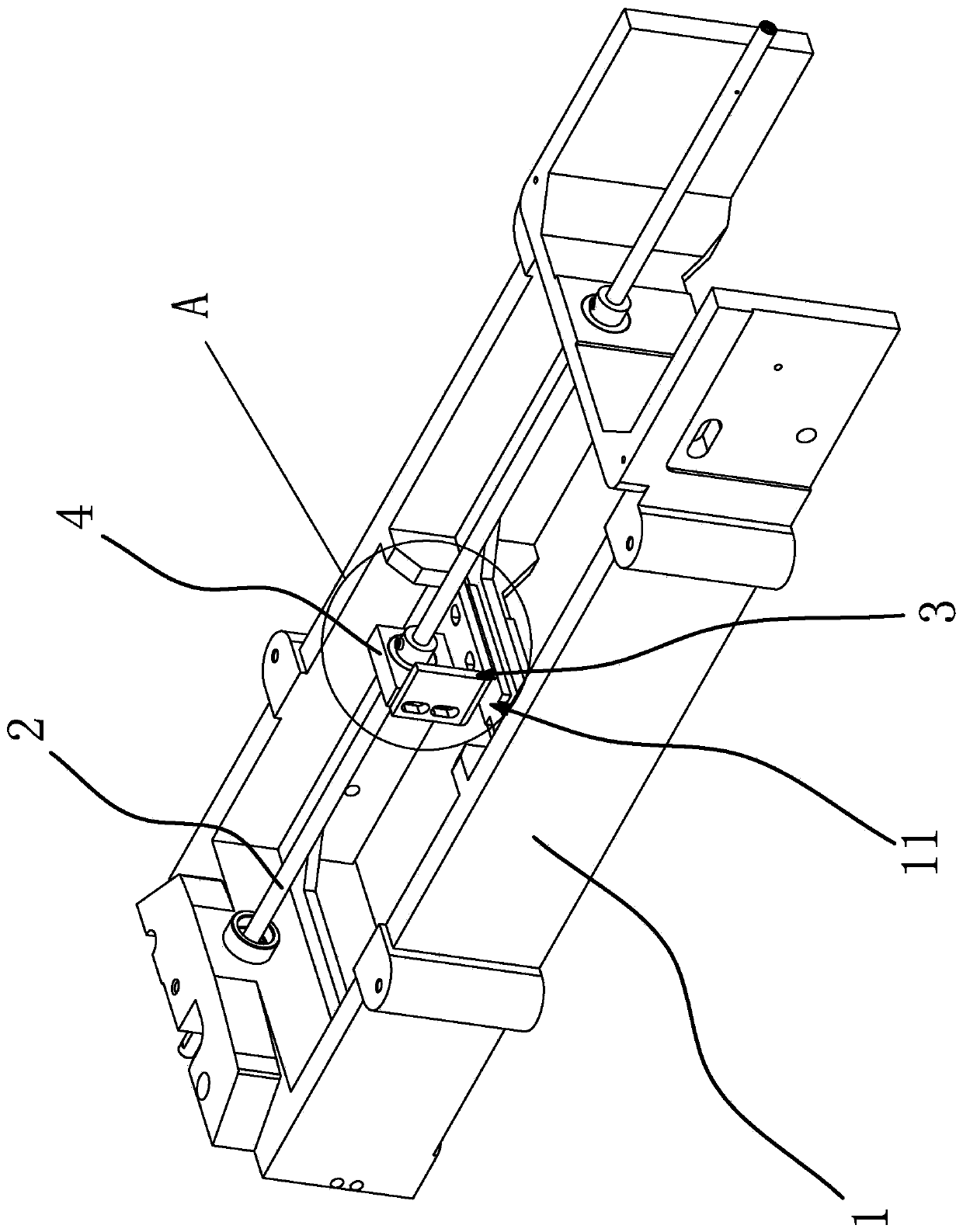

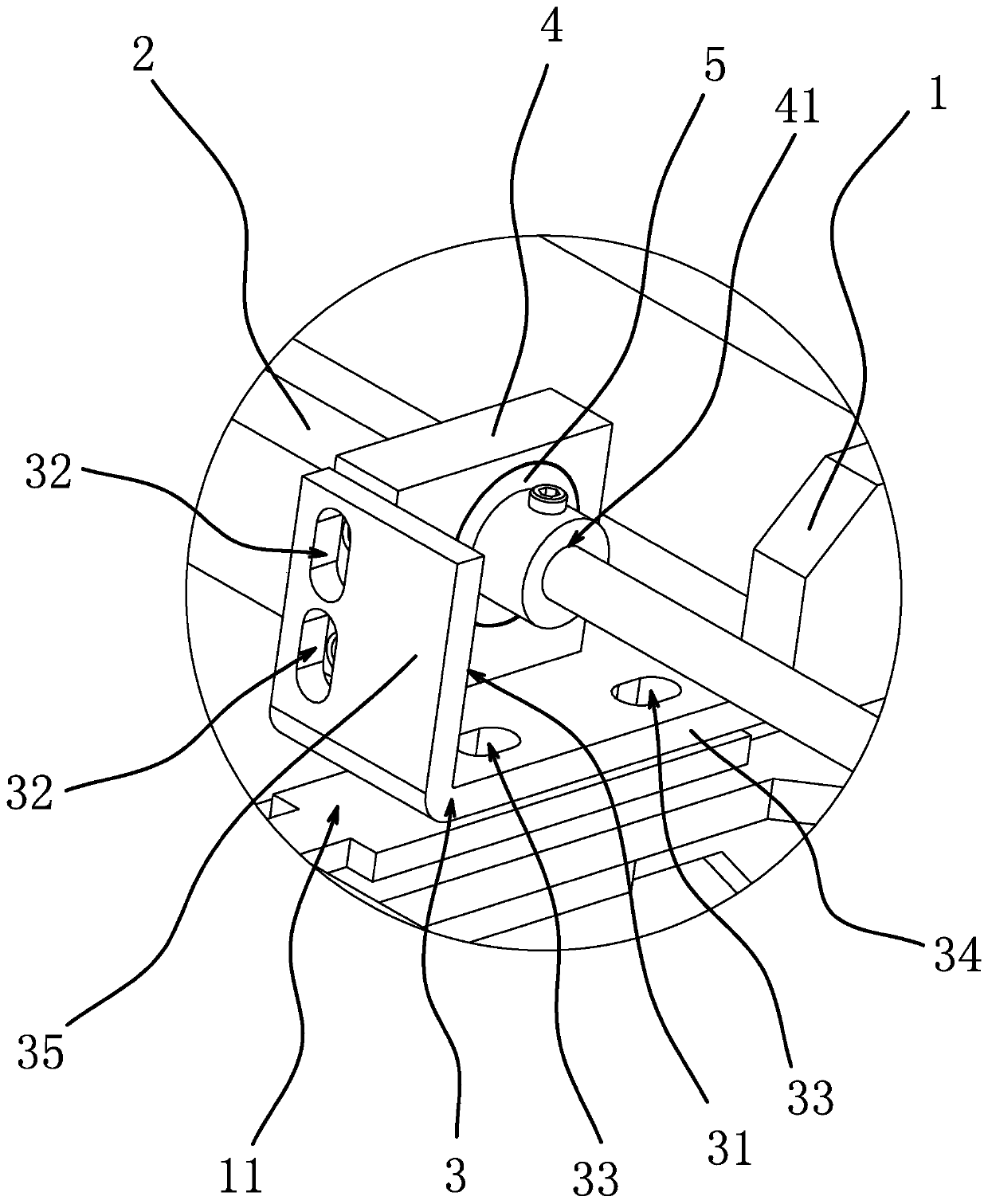

Transmission shaft support structure of sewing machine

ActiveCN110938947AImprove assembly accuracyLow machining accuracy requirementsSewing-machine control devicesEngineeringProcessing accuracy

Owner:ZHEJIANG BAOYU SEWING MACHINE

Pressure measuring element

InactiveCN109696229AWeighing apparatus using elastically-deformable membersWeighing apparatus detailsEngineeringSupport surface

Owner:FINE MECHATRONICS

Energy-storage phase-change material box for heat energy warehouse

InactiveCN104819586AAvoid getting lostSolar heat devicesSolar thermal energy generationThermal energyWater storage tank

Owner:戚荣生

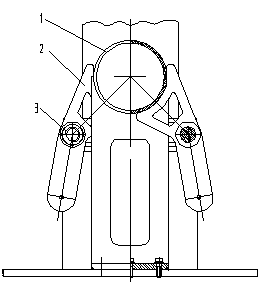

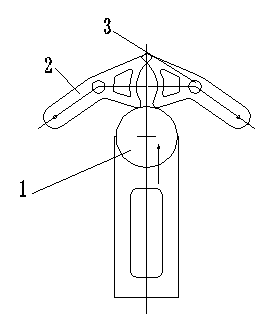

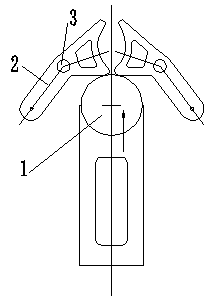

Device for eliminating circumferential stress of polished rod

PendingCN113738313AEliminate workExtended service lifeDrilling rodsFluid removalEngineeringSupport surface

The invention discloses a device for eliminating the circumferential stress of a polished rod. The device for eliminating the circumferential stress of the polished rod is arranged between balance iron and a beam hanger and comprises an upper supporting piece and a lower supporting piece, the upper supporting piece and the lower supporting piece are arranged in a spherical surface hinged mode, the top face of the upper supporting piece and the bottom face of the lower supporting piece are supporting faces arranged in parallel, a second center hole which is perpendicular to the supporting face and used for allowing the polished rod to penetrate through is formed in the upper supporting piece, and the aperture size of the second center hole is equal to the diameter size of the polished rod; a first center hole which is perpendicular to the supporting face and used for allowing the polished rod to penetrate through is formed in the lower supporting piece, and the aperture size of the first center hole is larger than the diameter size of the polished rod. The device can eliminate the circumferential stress of the polished rod to balance the stress of the polished rod, effectively straighten the polished rod to keep a well mouth centered, prolong the service life of the polished rod and reduce the occurrence of rod breakage accidents, and has important significance for ensuring the production of crude oil.

Owner:PETROCHINA CO LTD

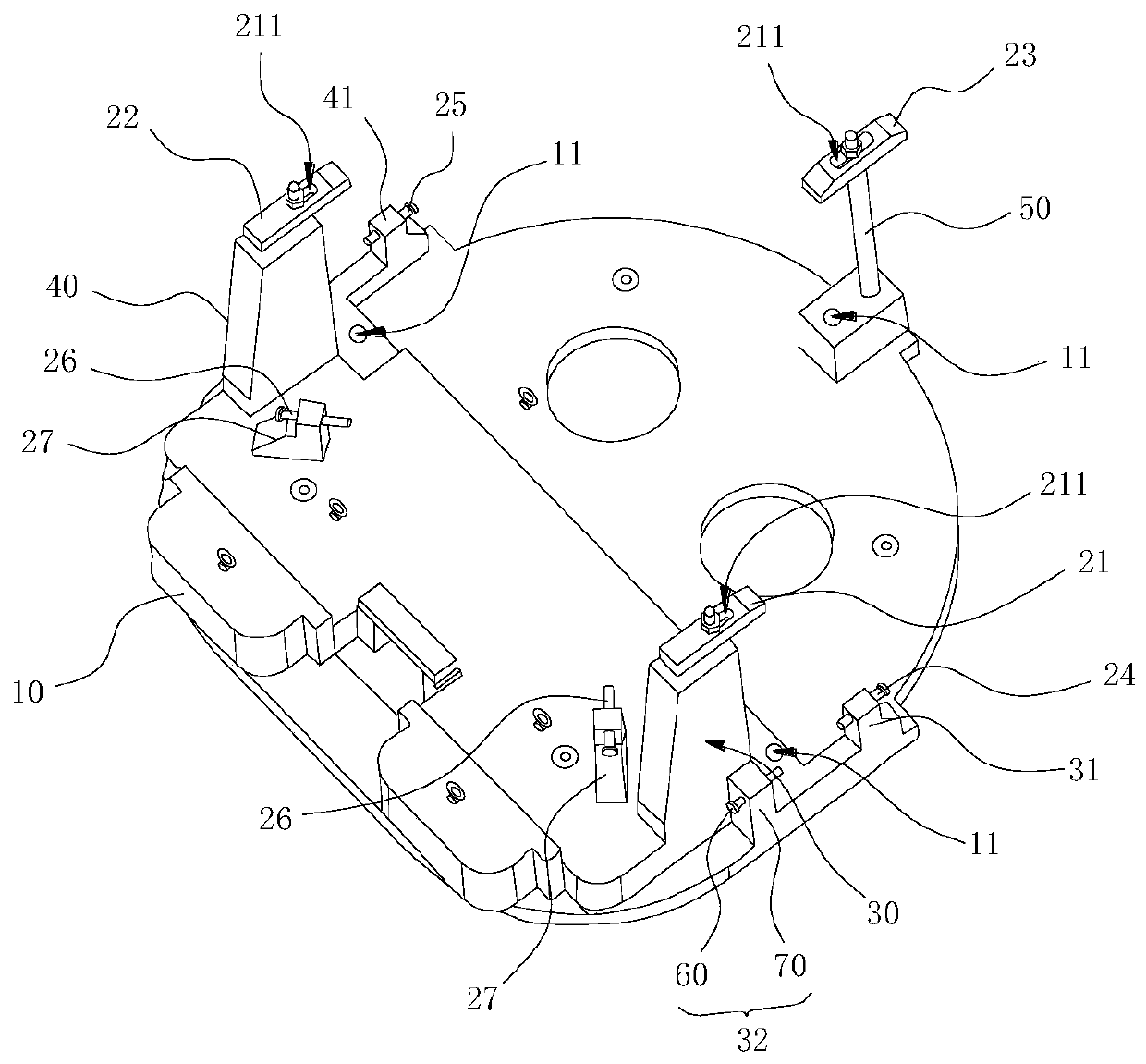

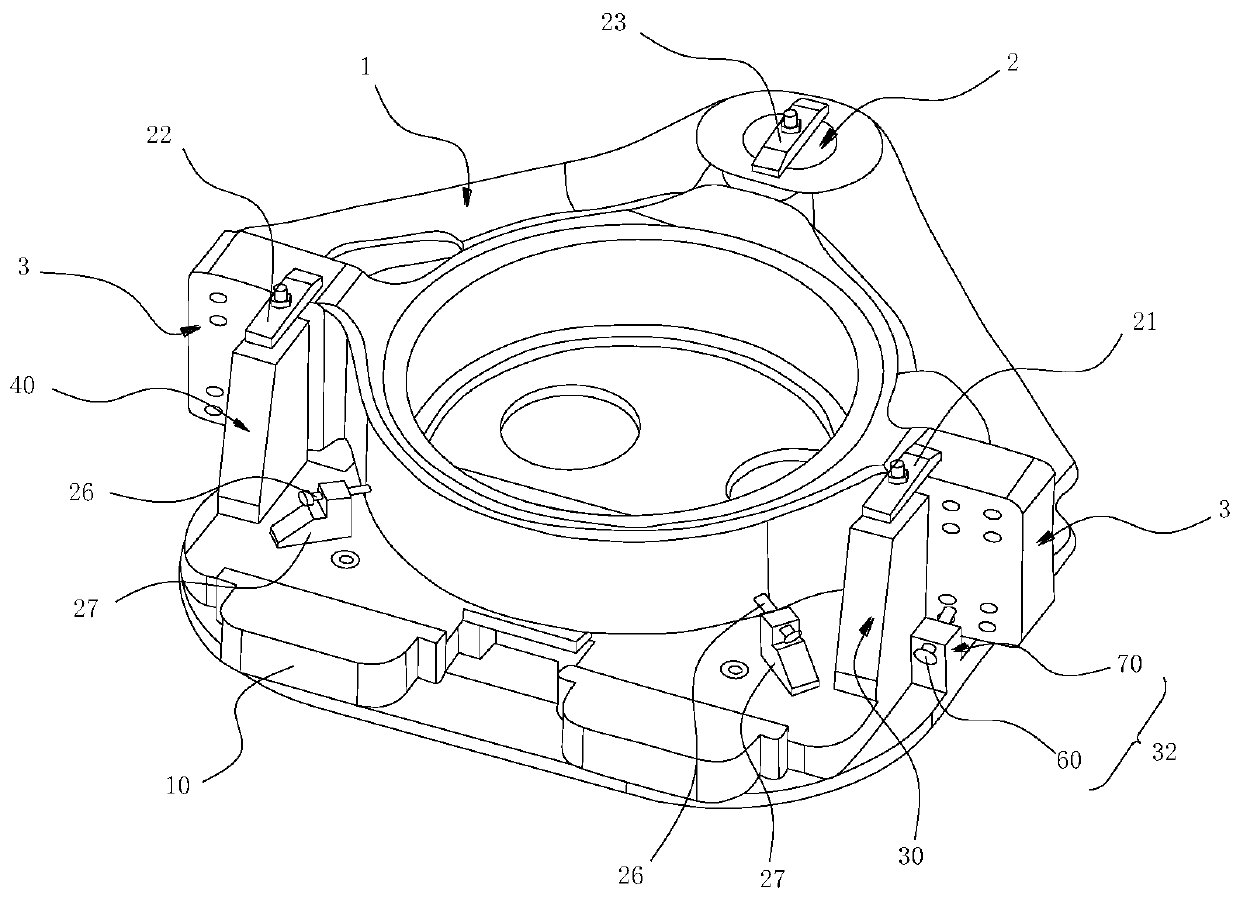

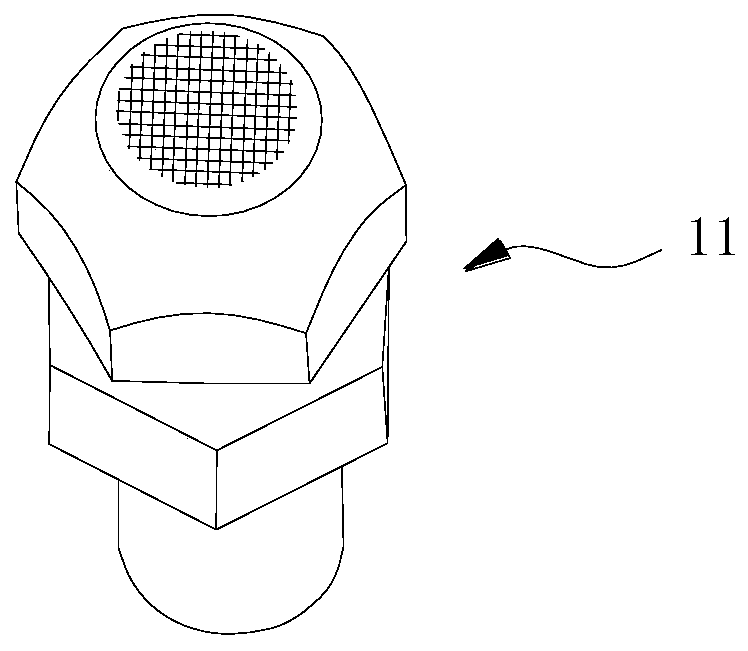

Fixture for porous and multi-plane finishing of large bearing seat castings

ActiveCN108544255BImprove stabilitySatisfy the positioning principleWork holdersPositioning apparatusMachiningIndustrial engineering

Owner:ANHUI YONGCHENG MACHINERY

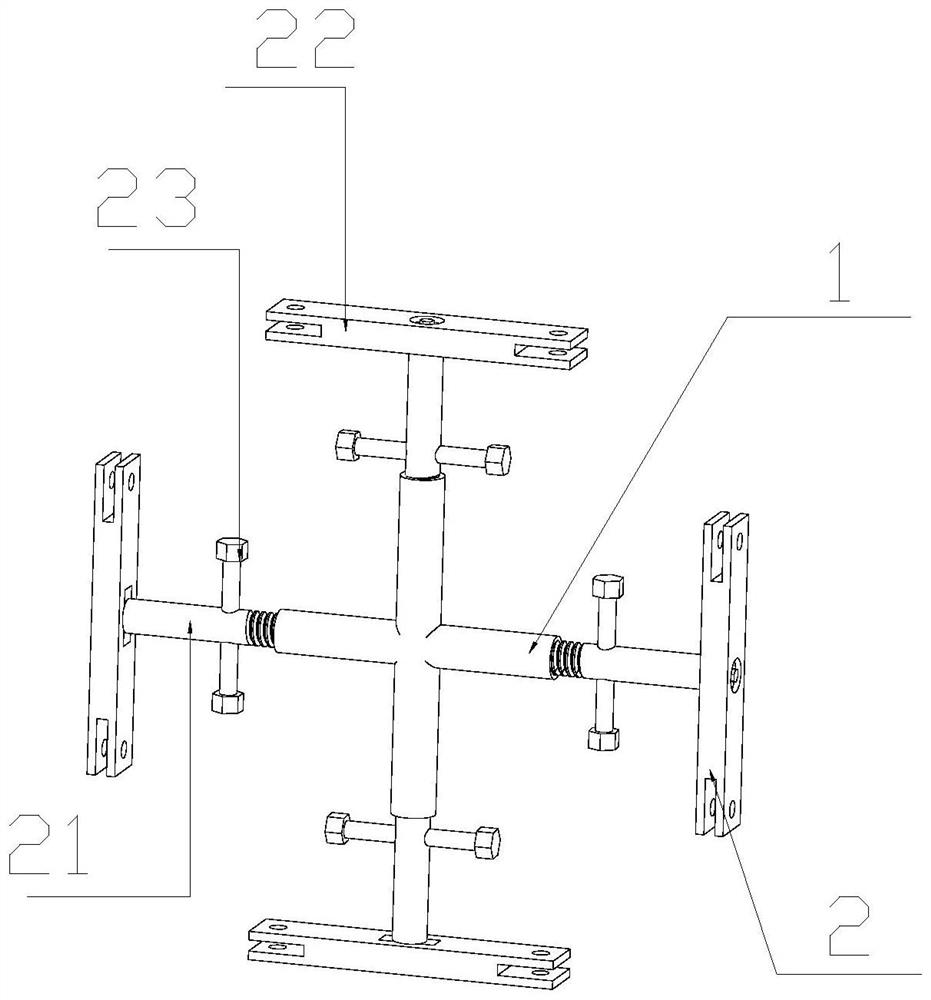

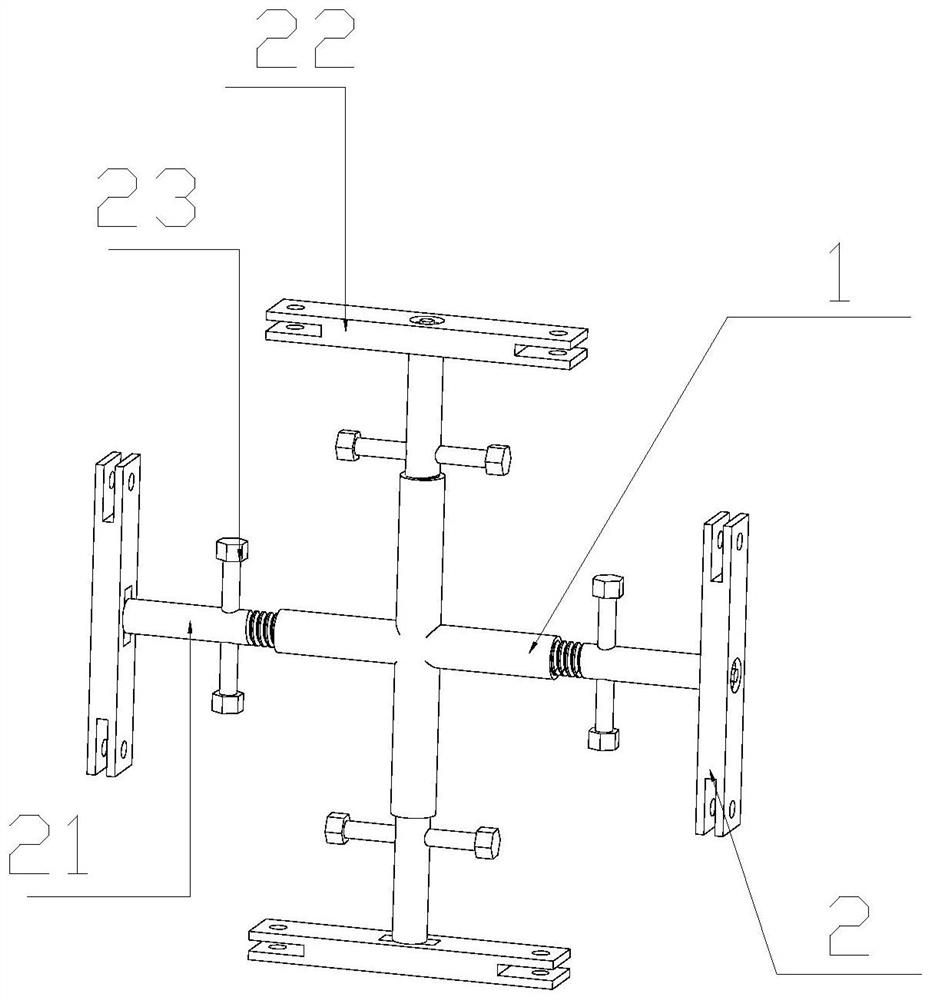

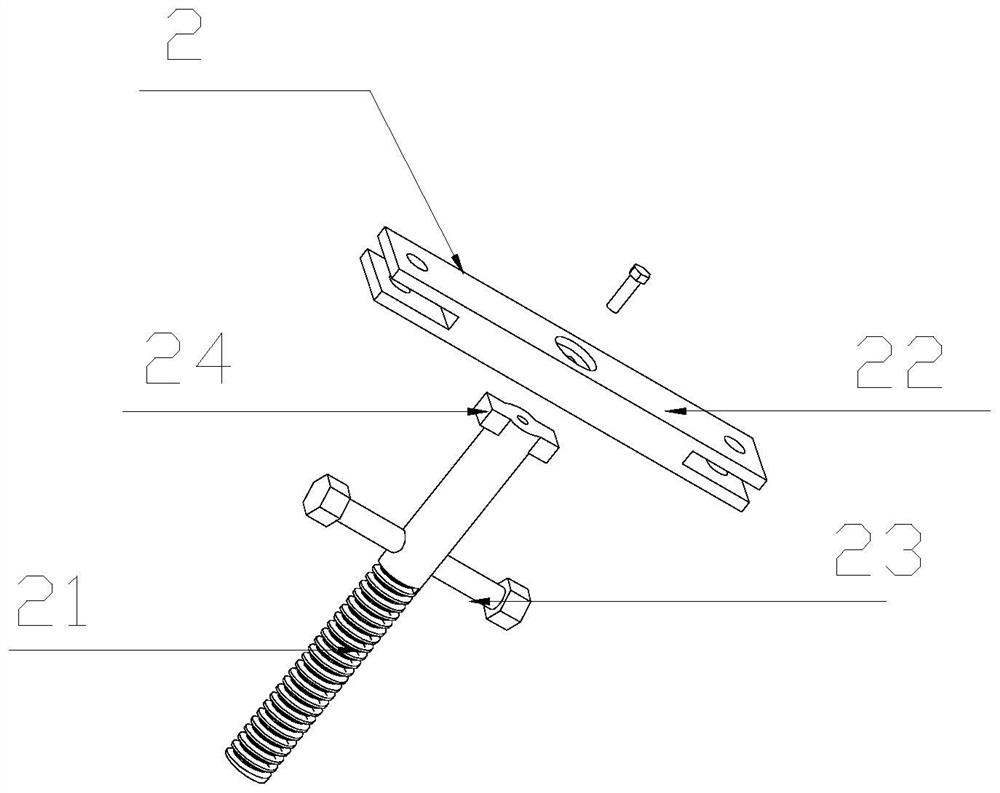

Adjustable portable template supporting device

PendingCN113958126AAdjustable support lengthAdjust the length of the supportFoundation engineeringForms/shuttering/falseworksEngineeringScrew thread

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap