LED lighting module

A technology of light-emitting diodes and lighting modules, which is applied in lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of small cross-sectional area in the heat dissipation direction, difficult to mass-produce, and difficult to age, and achieves quality control and assembly. Cost savings, reduction in the amount of hazardous substances, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

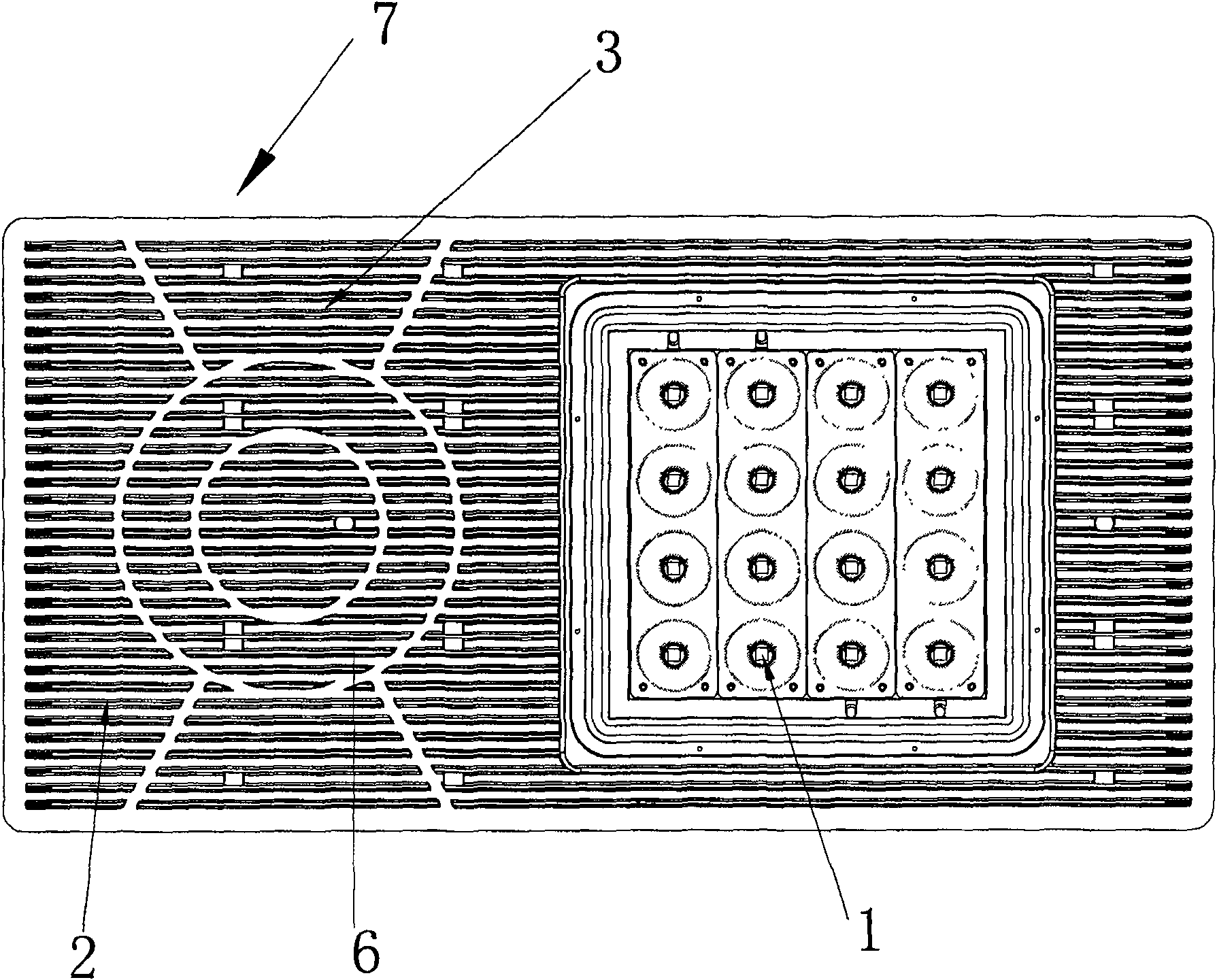

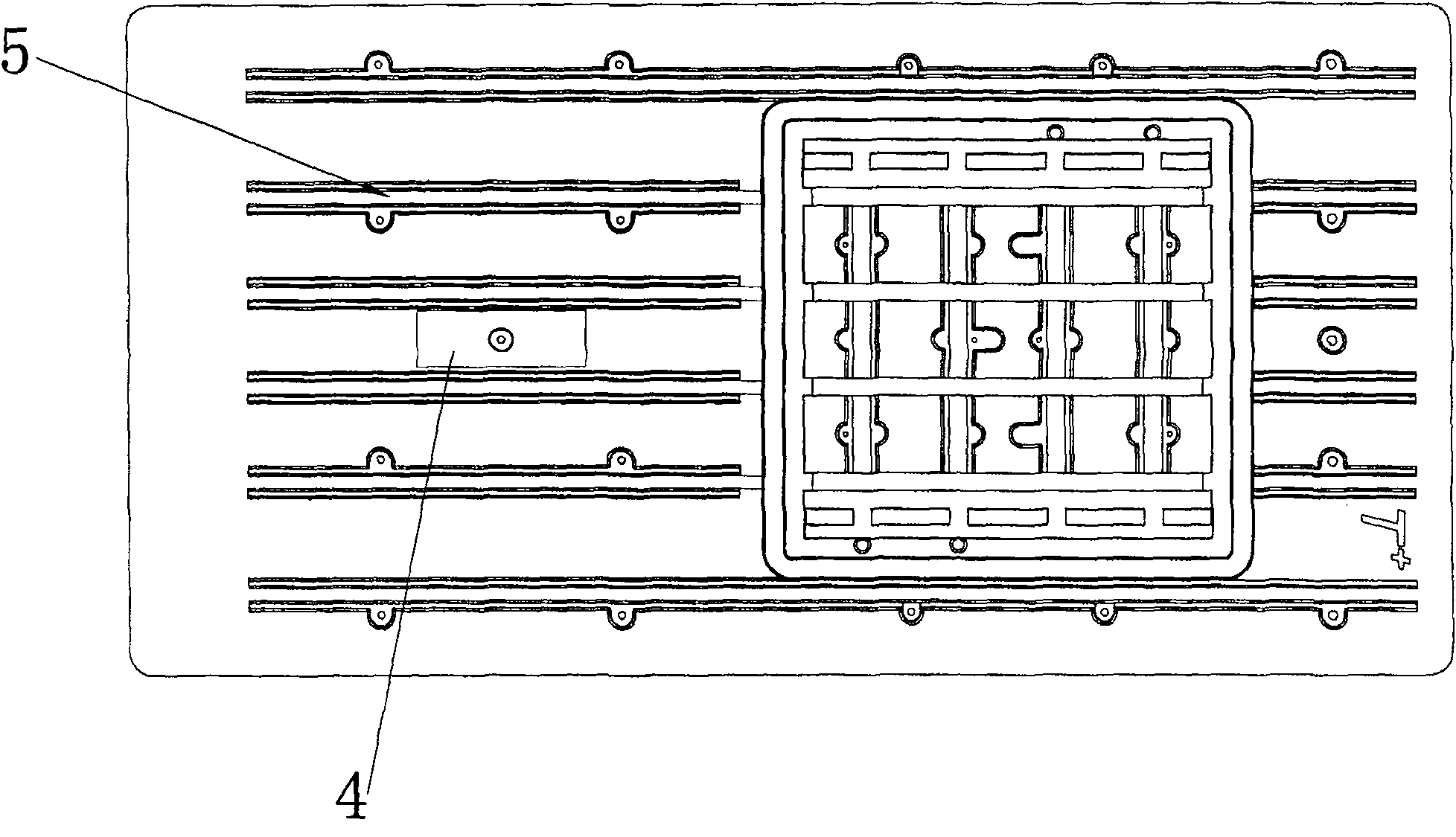

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention is mainly composed of an LED light source chip 1 and a heat sink 2 . A light source module is composed of at least two LED light source chips 1 , and the light source module, a heat sink composed of a heat dissipation module 3 , a power supply module 4 and a heat pipe 5 constitute a light emitting diode lighting module.

[0016] The light source module is composed of at least four LED light source chips 1, and a single chip is made of six-chip and frameless package, with a power range of 6-12W.

[0017] The light source module described in the invention is composed of at least four LED light source chips 1, and a single chip can also be: made of multi-chip red, green and blue mixed light and frameless packaging, with a power range of 6-12W.

[0018] The light source module is implanted with four red, green and blue mixed light LED chip

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap