Handcart propelling mechanism of single phase vacuum circuit breaker in electric railway user

A technology for vacuum circuit breakers and electrified railways, applied to electrical components, switchgear, pull-out switchgear, etc., can solve the problems of poor transmission stability, large mechanism volume, and inconvenient use, and achieve stable transmission, small size, Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

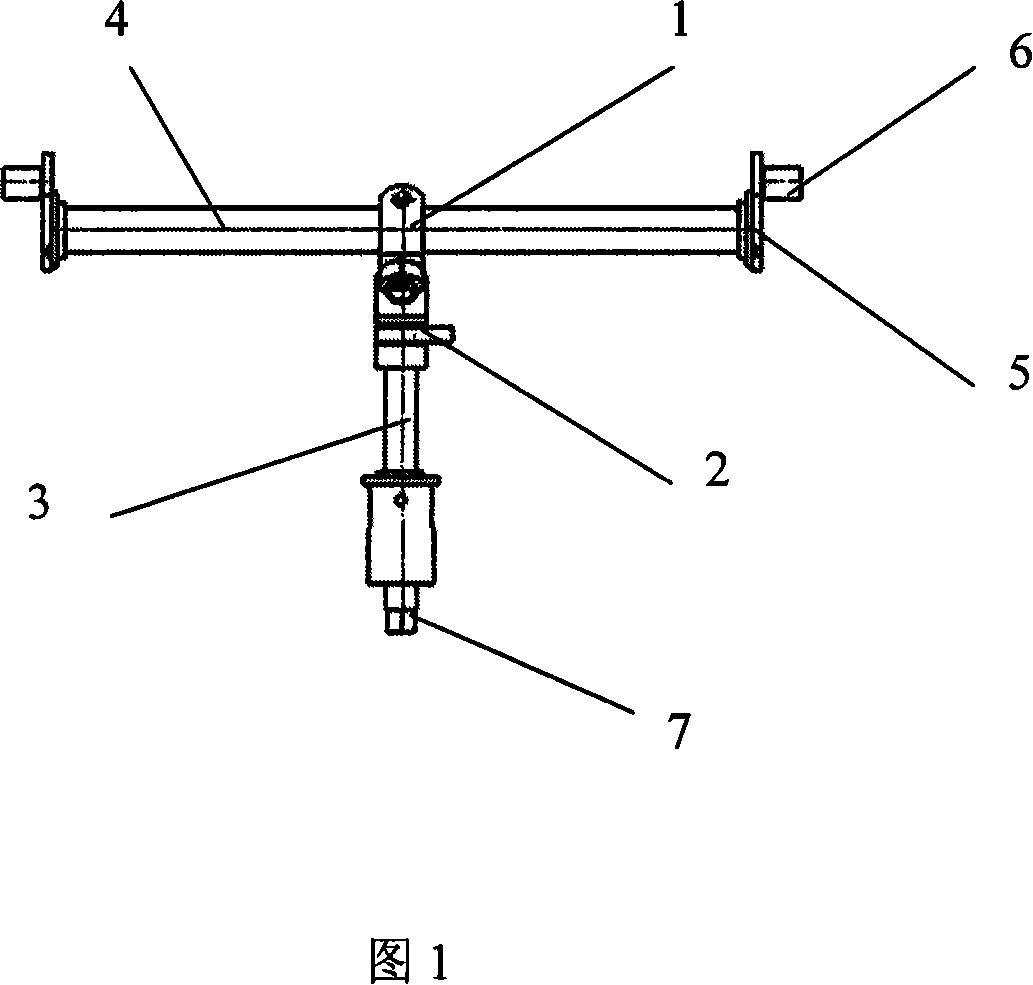

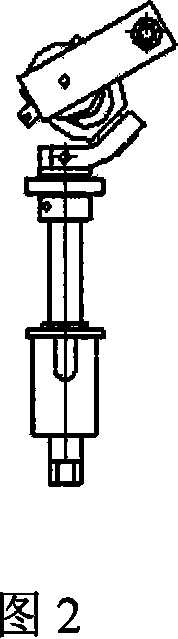

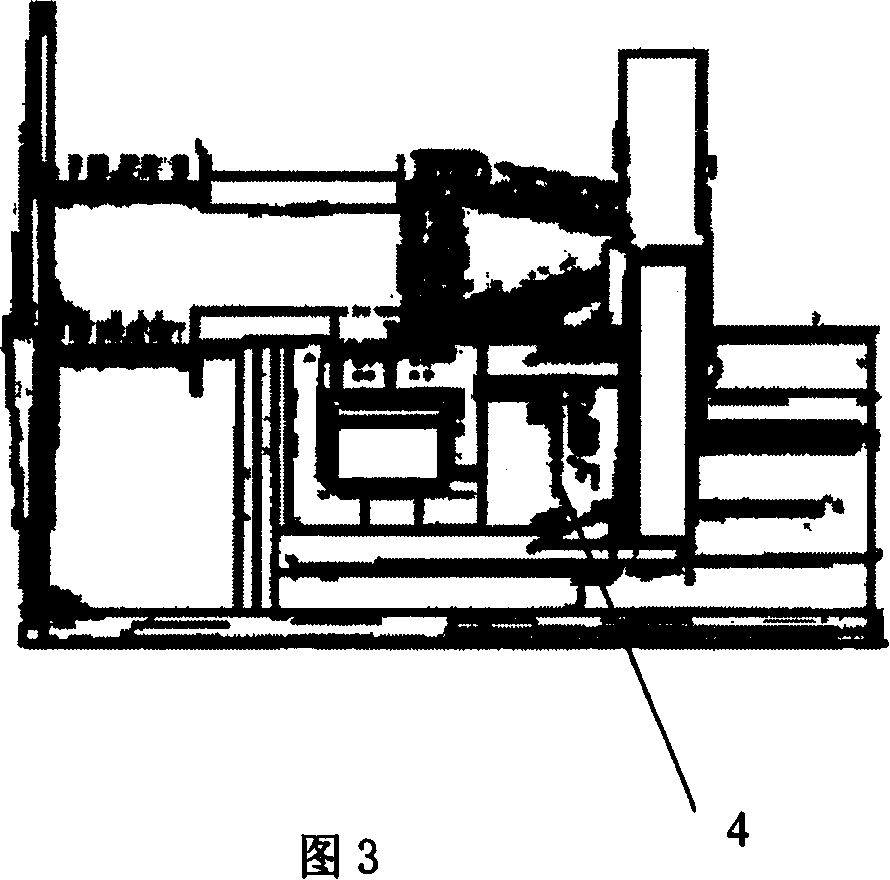

[0019] A handcart propulsion mechanism for an indoor single-phase vacuum circuit breaker for electrified railway users according to the present invention includes a transmission shaft 3, a bearing 2, a crank arm 1, a main shaft 4, an end plate 5, a roller 6 and a hexagonal end 7. The transmission shaft 3 is fixed under the handcart of the circuit breaker through the bearing 2 and the bushing. One end of the transmission shaft 3 is a hexagonal end 7 that matches the sleeve rocker arm. The other end of the transmission shaft 3 is composed of two crank arms 1. The ten bytes are connected to spindle 4. Rotate the hexagonal end 7 with the rocker arm to generate torque, so that the transmission shaft 3 rotates, and transmits to the main shaft 4 through the ten bytes formed by the two crank arms 1, so that the main shaft 4 rotates thereupon. The main shaft 4 is fixed on the lower part of the handcart of the circuit breaker and close to the track through bearings. Both ends of the main s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap