Non-welding flange-connection stainless steel metal flexible pipe and production method

A technology for metal hoses and manufacturing methods, applied in the direction of flange connections, hoses, hose connection devices, etc., can solve the problems of poor rubber corrosion resistance, backward processing technology, and low production efficiency, and achieve low cost and high structural form Simple and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A non-welded flange connection stainless steel metal hose and its manufacturing method of the present invention will be described in detail below in conjunction with the embodiments.

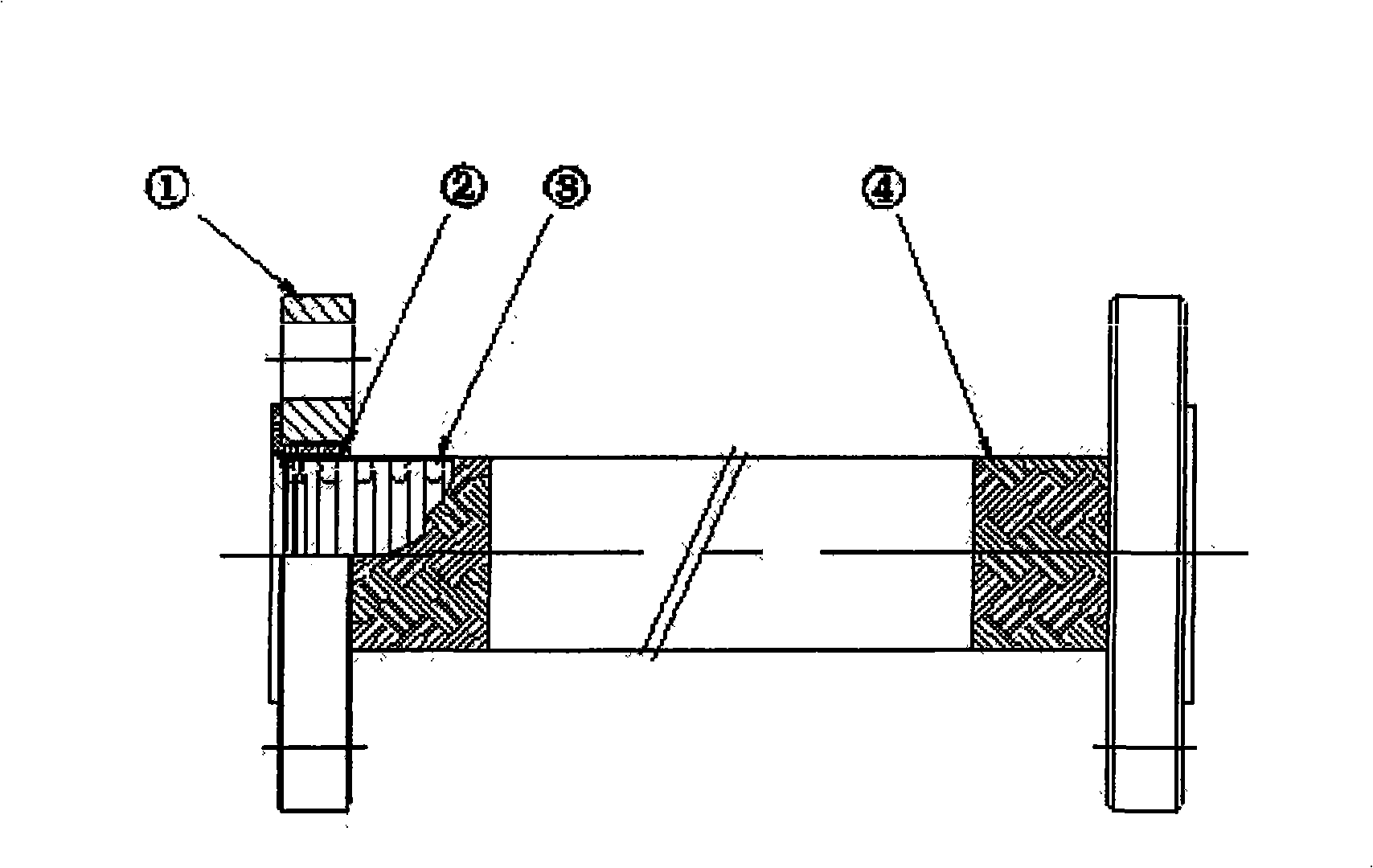

[0029] The structure of the non-welded flange connection stainless steel metal hose of the present invention is illustrated below with an example, please refer to the attached surface: figure 1 It is an explanatory diagram of the main parts of the non-welded flange connection stainless steel metal hose 3 of Example 1. The structure of the non-weld flange connection stainless steel metal hose 3 in Example 1 is a spiral or Ω-shaped structure that includes alternate peaks and troughs. Bellows, the stainless steel metal bellows 3 is covered with a cylindrical stainless steel soft metal mesh 4 woven by metal wires to prevent the stainless steel metal bellows from axially elongating and deforming due to internal pressure; and to protect the stainless steel metal bellows to a certain extent The cro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap