Slant clip soft-package production method and special die thereof

A technology of flexible packaging bags and production methods, which is applied in the field of special molds, can solve the problems of emission, easy splashing, and affecting sealing quality, etc., and achieve the effect of ensuring hygiene, high quality, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

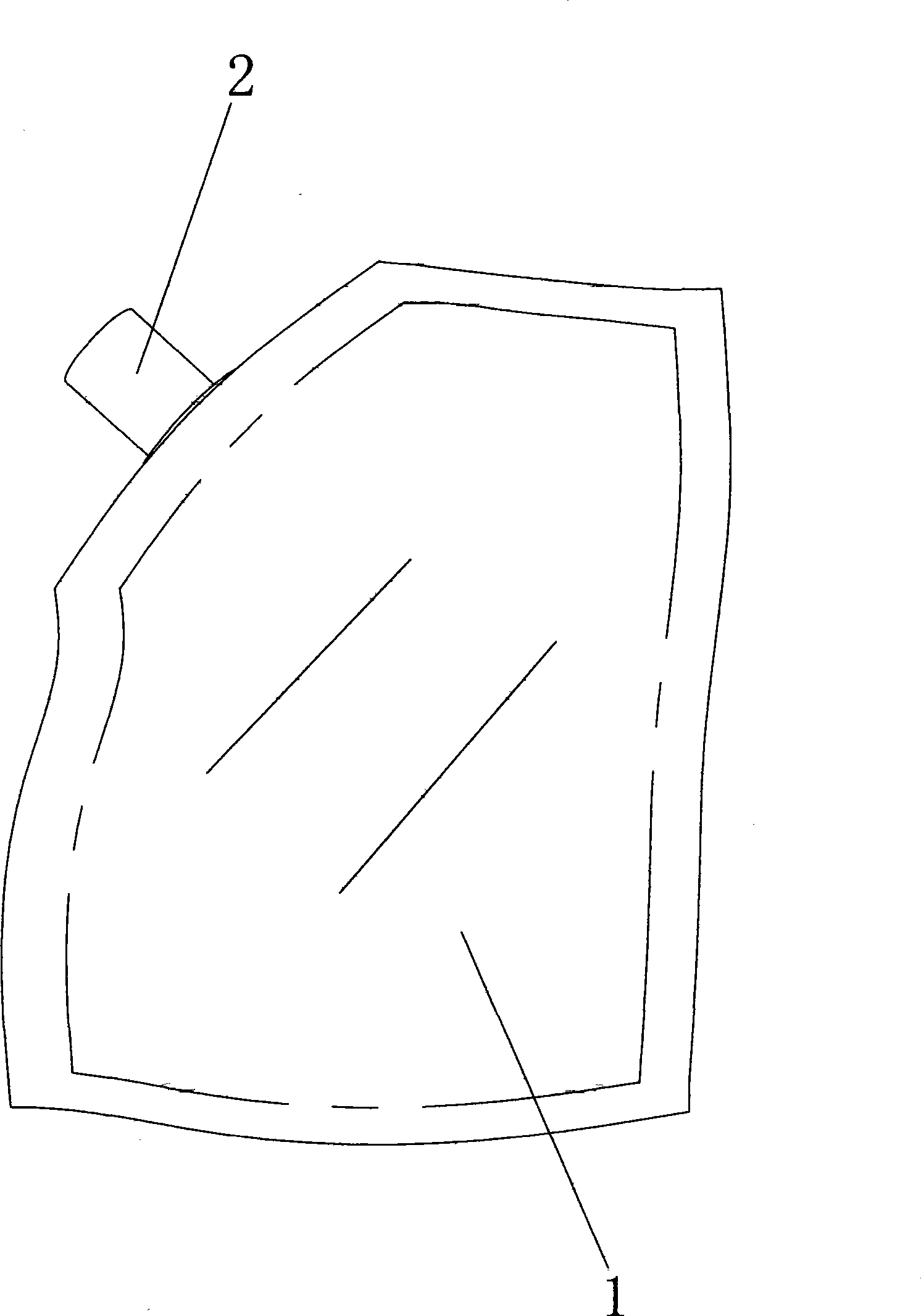

[0026] A method for manufacturing a flexible packaging bag with an oblique clip spout includes the following steps:

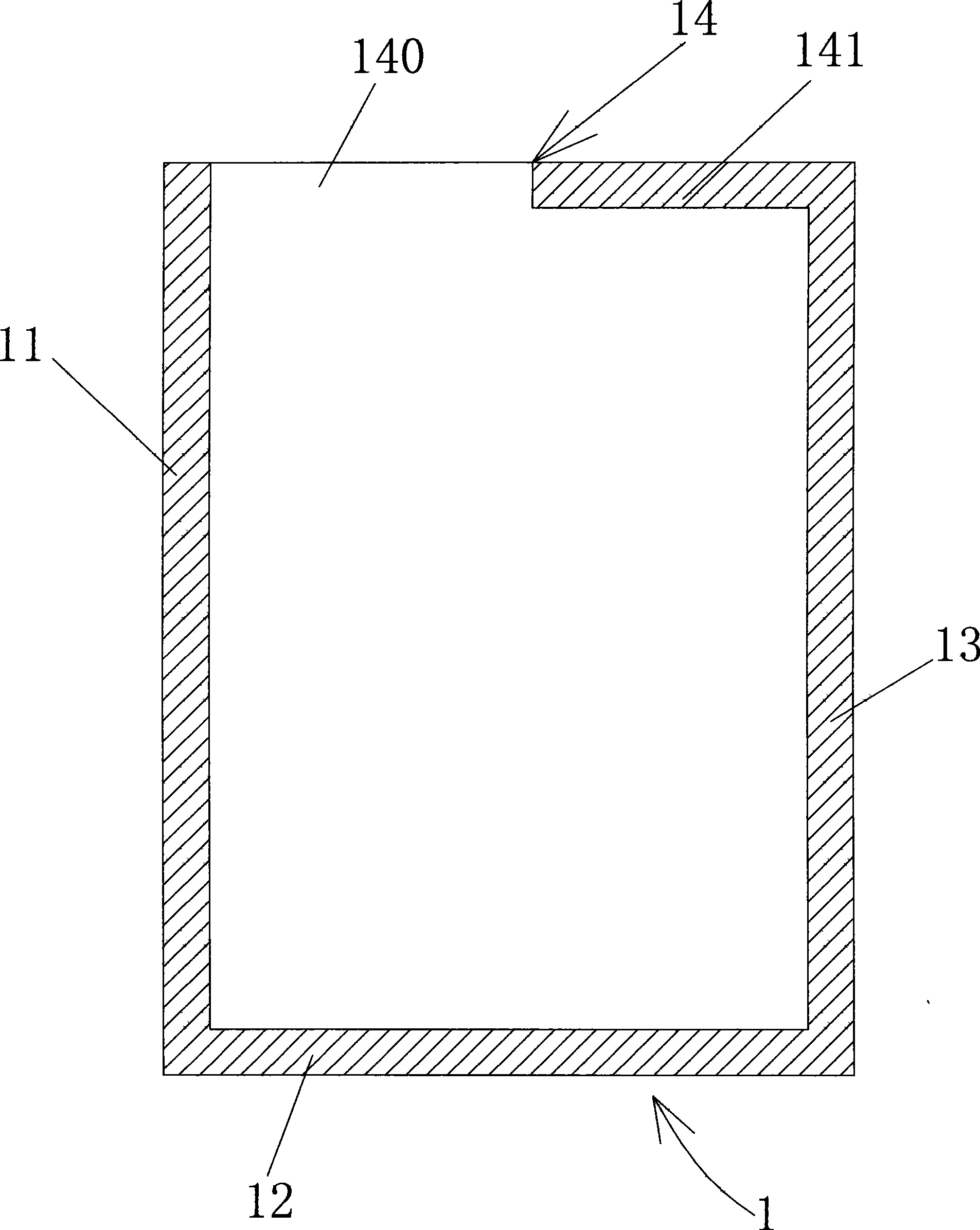

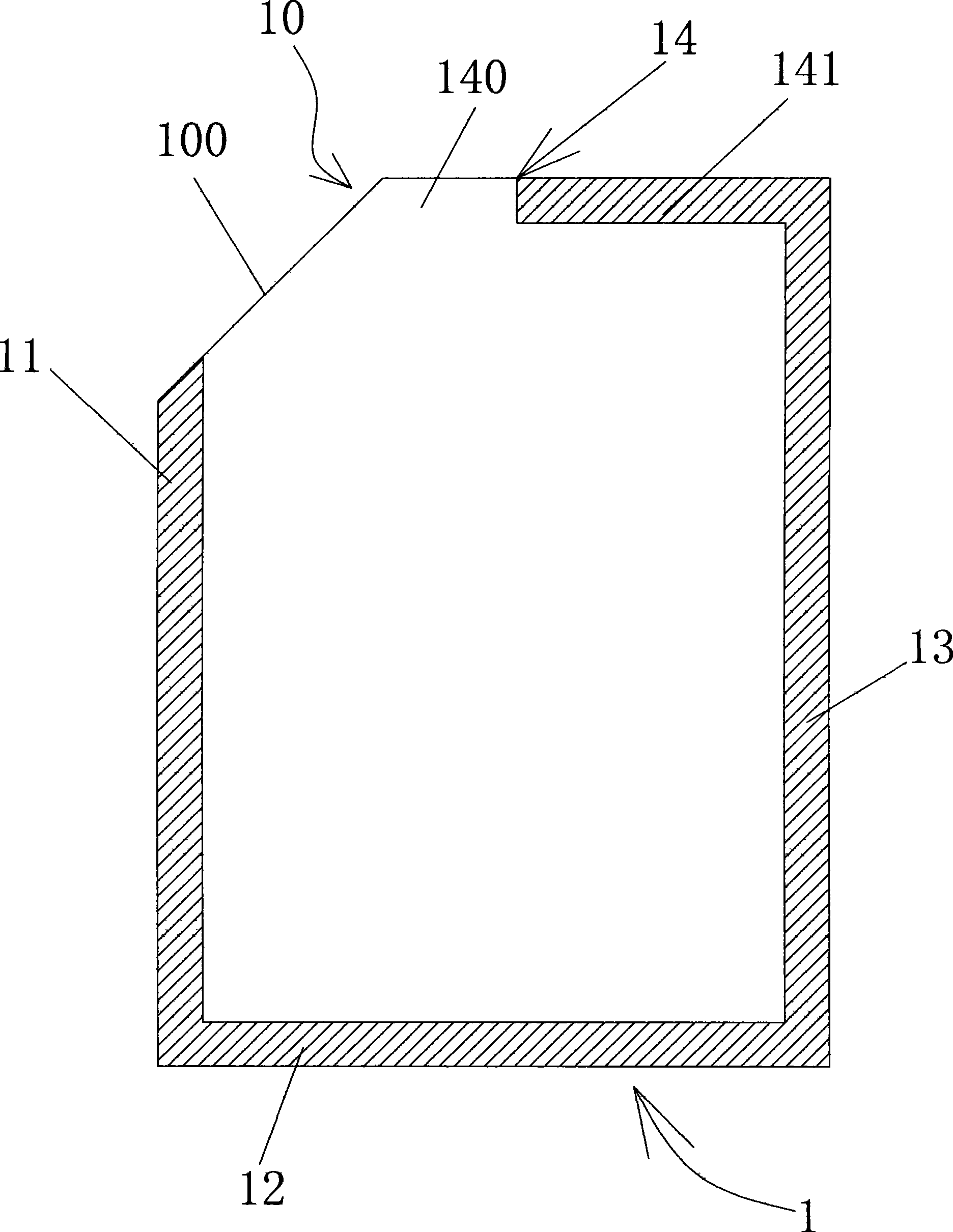

[0027] a. Heat sealing: the first side 11 and the third side 13 of a rectangular bag body 1 are longitudinally sealed first, that is, heat-sealed with parallel and equal hot pressing sheets spaced at a certain distance. This process is carried out on the conveyor belt. The above bag making machine is completed; the second side 12 and the fourth side 14 are horizontally sealed with parallel and unequal hot pressing sheets, so that the fourth side 14 of the bag body 1 is partially heat-sealed to form an opening section 140 And the half-sealed section 141. In the present invention, the first side 11, the second side 12, the third side 13 and the half-sealed section 141 on the fourth side 14 are connected in sequence, and one end of the half-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap