Individual soldier water purifier applying composite nano water purifying material

A water purifier and nanotechnology, applied in the field of individual water purifiers, can solve the problems of many water purification equipment, difficult regeneration, secondary pollution, etc., and achieve the effects of light equipment, simple assembly method, and simple regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The making of a kind of personal water purifier

[0031] a. Make the overall frame of the filter element according to the following dimensions:

[0032]

[0033] Wherein the thickness of the outer edge 406 is 1.00mm.

[0034] Frame structure: 4 vertical columns, column spacing 19.68mm, column width 2.00mm;

[0035] 20 rows horizontally, the row spacing is 3.00mm, and the row width is 2.00mm;

[0036] The arm thickness of the frame is 1.50mm;

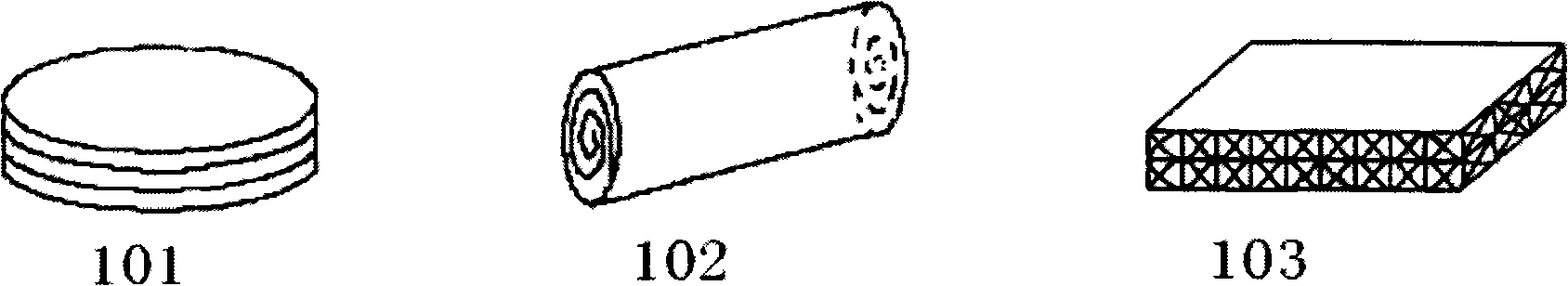

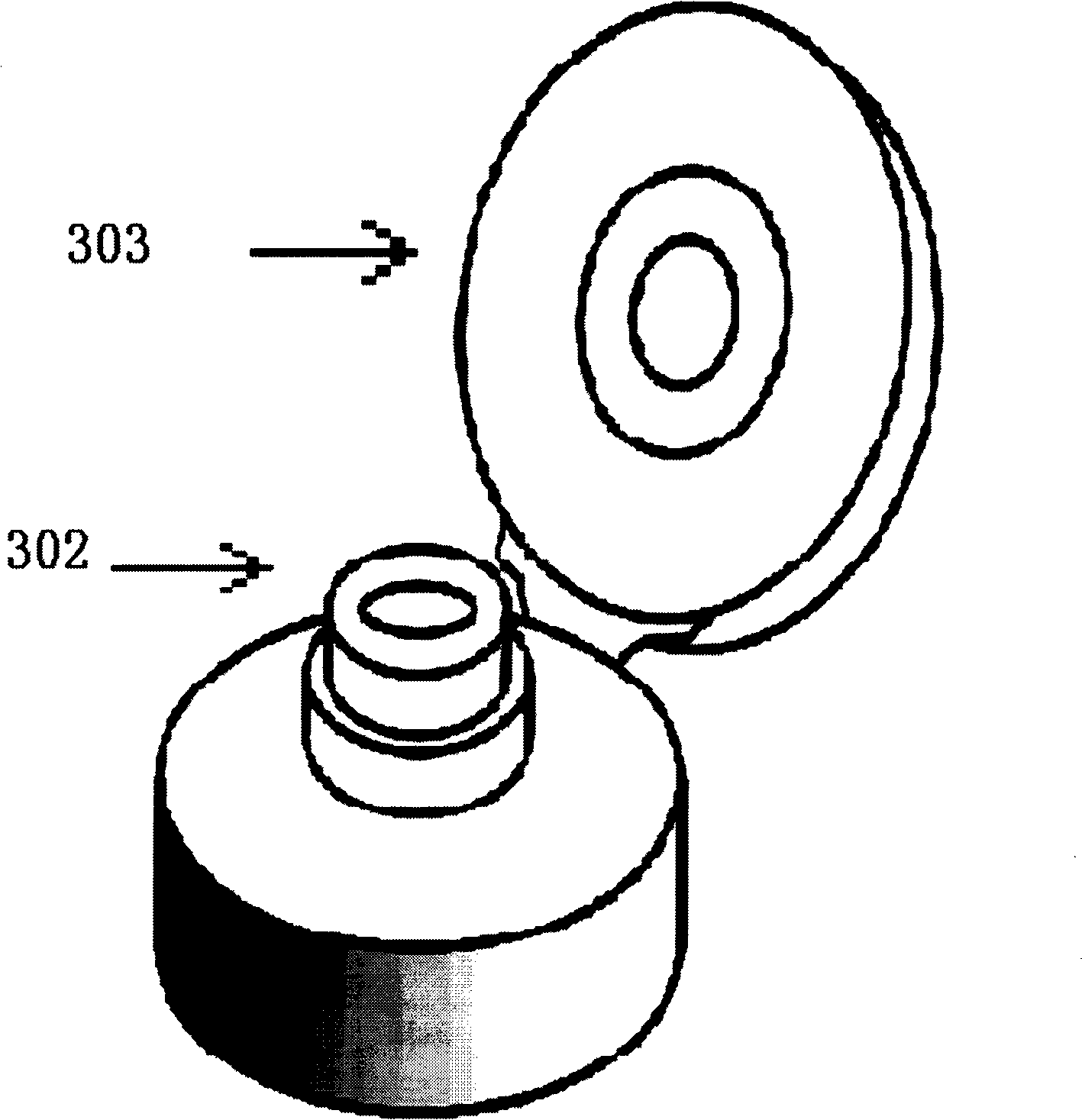

[0037] b. Tightly wrap the prepared sheet-like composite nano water purification material on the frame of the filter element, and then wrap it with a tape to fix it. The thickness of the nano material and the tape is 1.00mm; for the separate upper cover and lower Bottom and frame, the upper cover, lower bottom and frame can be bonded and sealed together with water-based polyurethane adhesive, and the filter element is now manufactured;

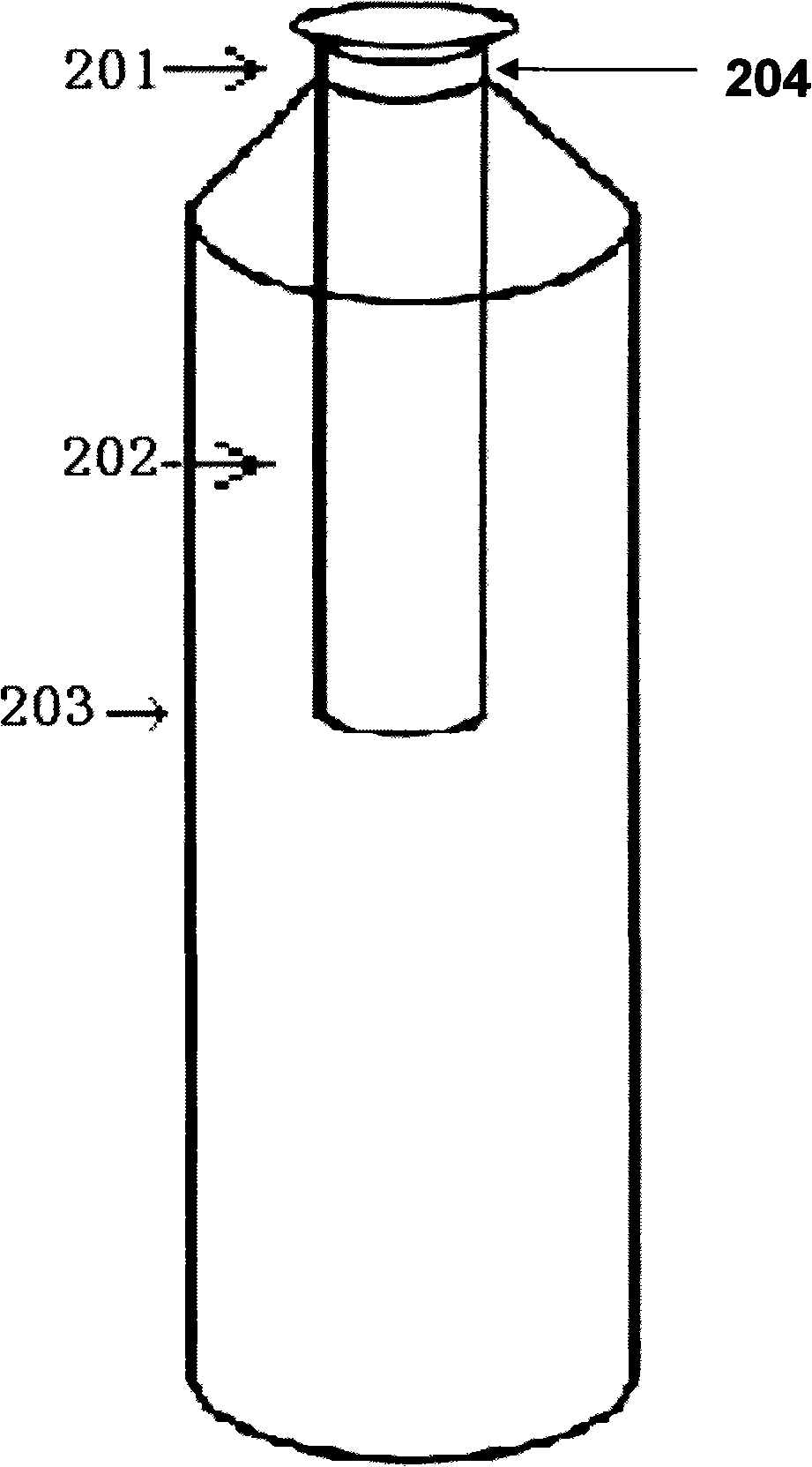

[0038] c. Select the bottle body: the diameter of the bottom of the bottle i

Embodiment 2

[0041] Embodiment 2: Experiment of applying composite nanometer water purification material

[0042] A in Table 1 is the data of the total number of bacteria changing with time in the process of treating sewage containing bacteria with the individual water purification equipment of the present invention and the filter element made of composite nanomaterials. In the bacteriological determination of water, the method of direct inspection of various pathogenic microorganisms in water is relatively complicated, and some are difficult, and the negative inspection result cannot guarantee absolute safety. Therefore, in actual work, the total number of bacteria in the water is often used to indirectly judge the hygienic quality of the water (see "Water and Wastewater Detection and Analysis Methods" P575). my country's domestic water hygiene standard (GB 5749-85) stipulates that the effluent standard for the total number of bacteria is 100 / ml. Use a constant temperature incubator (temp

Embodiment 3

[0050] Embodiment 3: Experiment of application of regenerative composite nanometer water purification material

[0051] In table 2, A is the filter element made after using the individual water purification equipment of the present invention to regenerate the used composite nanomaterials of A in table 1 (the used nanometer water purification materials are regenerated in an autoclave). , in the process of treating sewage with a fixed number of bacteria, the data of the total number of bacteria changing with time. The test method is the same as the determination of A in Table 1. The removal efficiency of bacteria in the first 25 minutes in the table is 100%. After 25 minutes, the removal efficiency of bacteria gradually decreases. At 590 minutes, the bacteria always start to exceed the standard, and at 817 minutes, the material’s ability to treat bacteria in water reach maximum saturation. It can be seen that the nano water purification material of the present invention is easy to

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap