Device for adjusting electro-hydraulic inclination angle of screen box of vibrating screen and method for using same

A technology of adjusting device and sieve box, applied in chemical instruments and methods, sieves, earthwork drilling, etc., can solve problems such as unfavorable equipment integration modernization, manpower, time waste, etc., to save manpower, improve work efficiency, and facilitate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

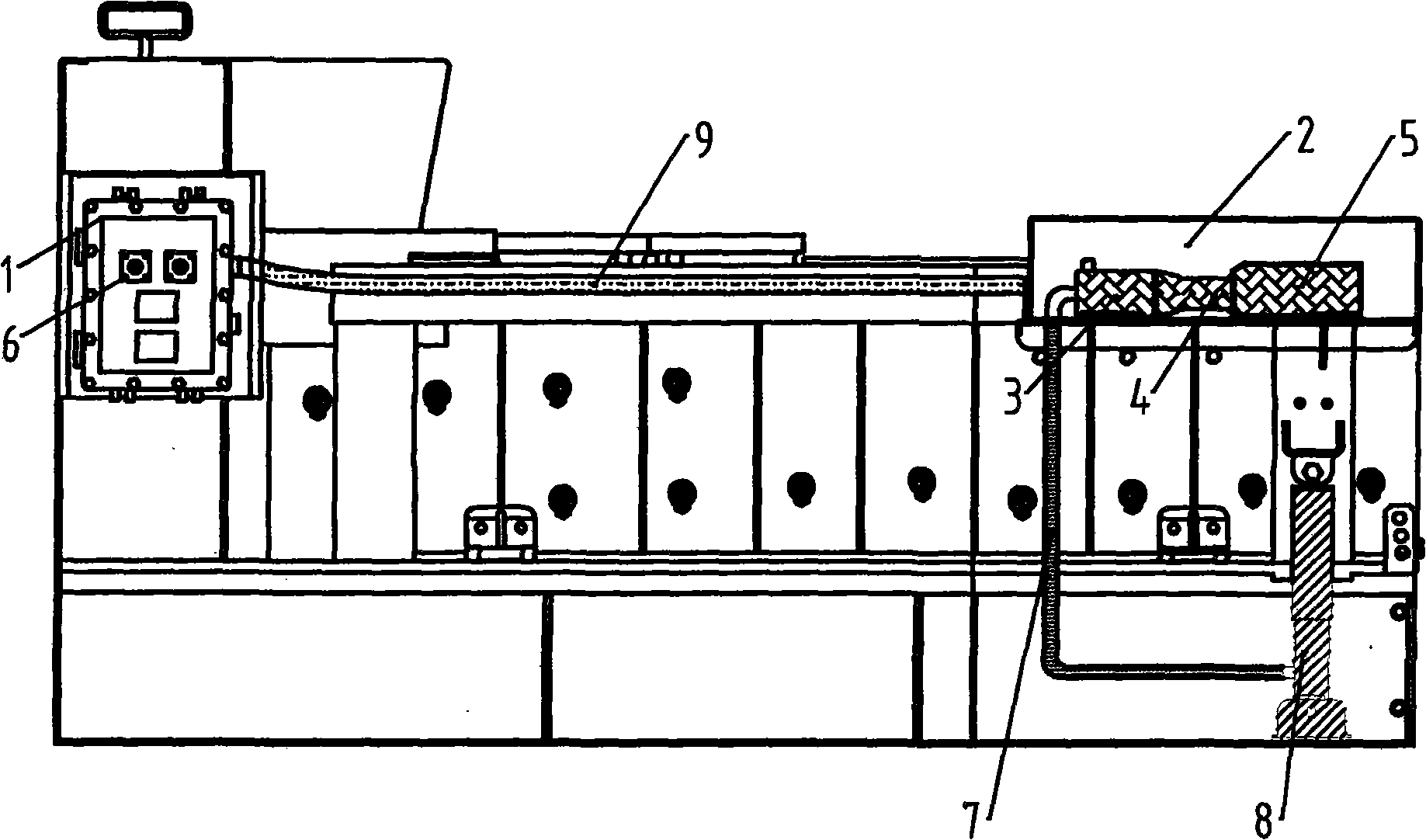

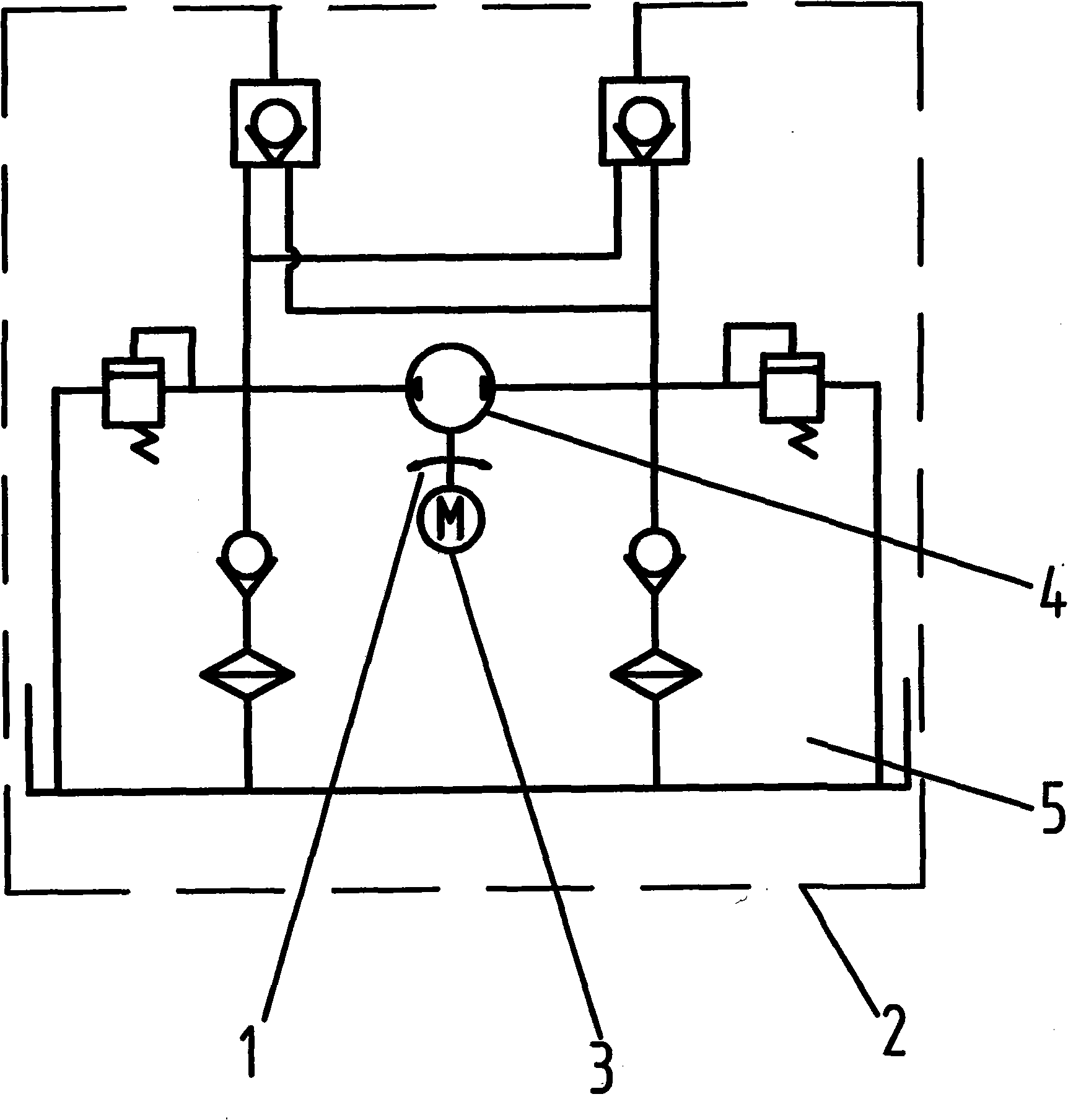

[0007] exist figure 1 with figure 2 Among them, the electro-hydraulic inclination adjustment device of the vibrating screen box is formed by connecting the electric control system 1 and the hydraulic system 2. In the electric control system 1, the motor 3 is connected to the oil pump 4, and the electric control system 1 is connected to the motor 3 through a cable 9. There is a control panel 6 on the electric control system 1; the oil tank 5 in the hydraulic system 2 is connected with the hydraulic cylinder 8 by the hydraulic pipeline 7; when working, the motor 3 can be reversed, and the two-way oil pump 4 controls the flow of the oil circuit when the motor 3 operates broken. When the control panel 6 controls the motor 3 to rotate forward, the two-way oil pump 4 is forwardly connected, the hydraulic oil in the oil tank 5 enters the hydraulic cylinder 8 through the hydraulic pipeline 7, the hydraulic cylinder 8 stretches out, and the equipment realizes the upward adjustment of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap