Improved manual release device for electro-hydraulic disc brake

A disc brake and manual release technology, applied in the direction of brake actuators, etc., can solve the problems of inconvenient operation of manual pumps, not very smooth, causing accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

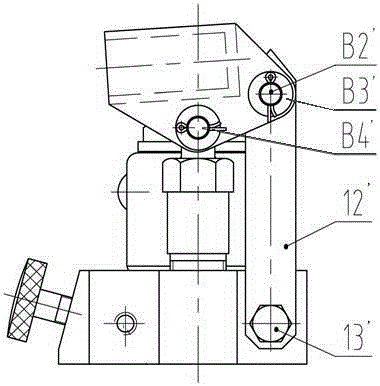

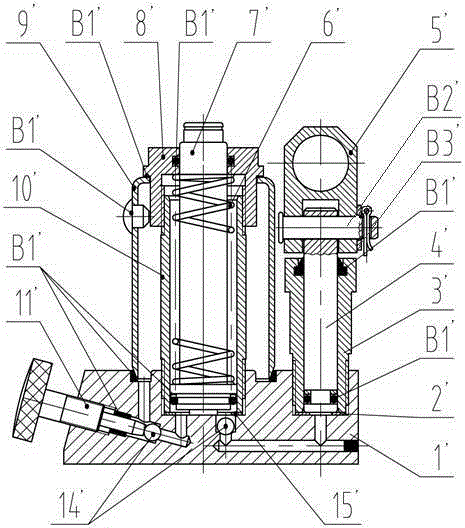

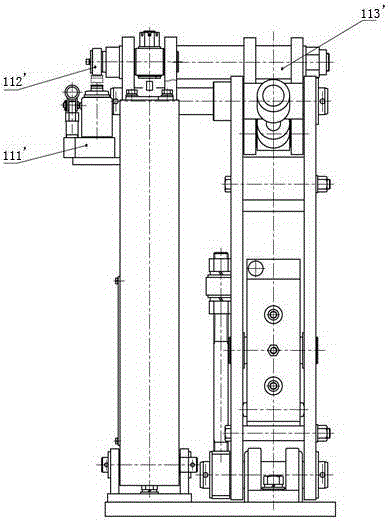

[0028] Such as image 3 , Figure 3a , Figure 3b As shown, an improved manual release device for electrohydraulic disc brakes of the present invention includes a base 1, an operating cylinder 3, a piston rod A7, a booster rod seat 6, a connecting rod 17, a rotating support 4, a working Oil cylinder 10, piston rod B13 and oil tank 11,

[0029] Both the operating cylinder 3 and the working cylinder 10 are fixed on the base 1, the operating cylinder 3 is connected with the base 1 through threads, the piston rod A7 and the operating cylinder 3 are in clearance fit, and are sealed by the sealing ring B4 to prevent the hydraulic oil from leaking out. The afterburner rod seat 6 is connected with the p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap