Method for designing internal-rotation constant pressure pump structured as external rotator

A design method and technology of constant pressure pumps, applied to components of pumping devices for elastic fluids, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve difficult to withstand high pressure and sealing problems Problems such as that have not been fundamentally resolved, to achieve the effect of low manufacturing cost, simple structure, and no pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

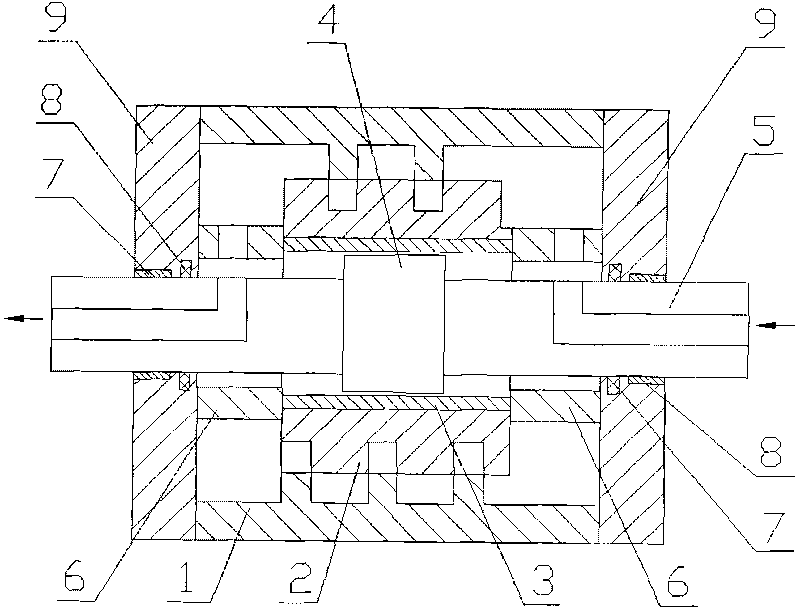

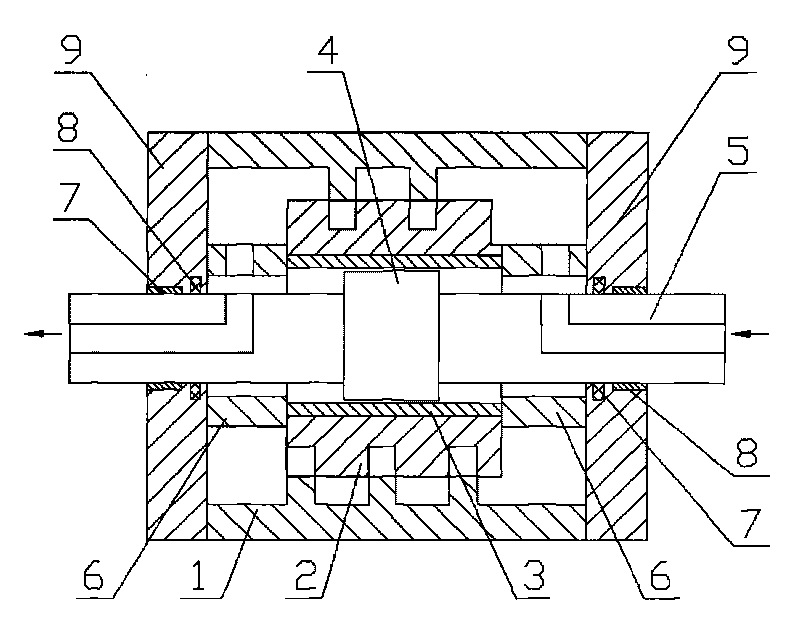

[0029] Example figure 1 As shown, the external rotation internal rotation constant pressure pump consists of a pump body 1, a spiral groove body 2, a universal rotation sleeve 3, an eccentric sleeve 4, an eccentric shaft 5, a ring track 6, a bearing 7, an oil seal 8, a transparent end cover 9, and The end cap 10 and the sealing ring are connected, and except the sealing ring, all other parts are rigid materials. The eccentric sleeve 4 is fixedly sleeved on the axial surface of the eccentric shaft 5, and the eccentric sleeve 4 and the eccentric shaft 5 are threaded or keyed, and can also be an integral structure. Since the eccentric sleeve 4 is a wearing part, it is separated The structure only needs to replace the accessories of the eccentric sleeve 4 to prolong the service life of the eccentric shaft 5, and the eccentric sleeve 4 can realize self-adjustment to meet the trajectory requirements of the spiral groove body 2 for planetary motion. The outer surface of the pump body 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap