Manual device for nuclear power

A manual and nuclear power technology, applied in the field of valve control devices, can solve the problems of failing to meet the requirements and high requirements of the gearbox, and achieve the effects of strong air tightness, large transmission ratio, and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

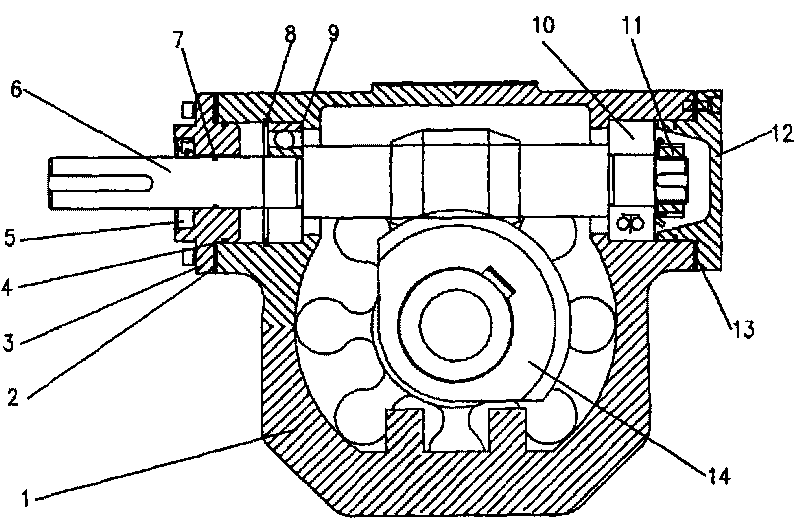

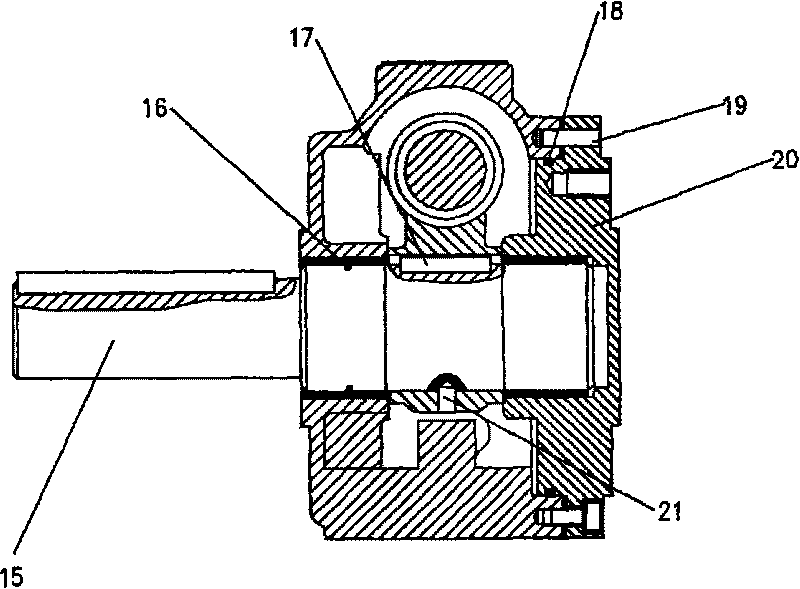

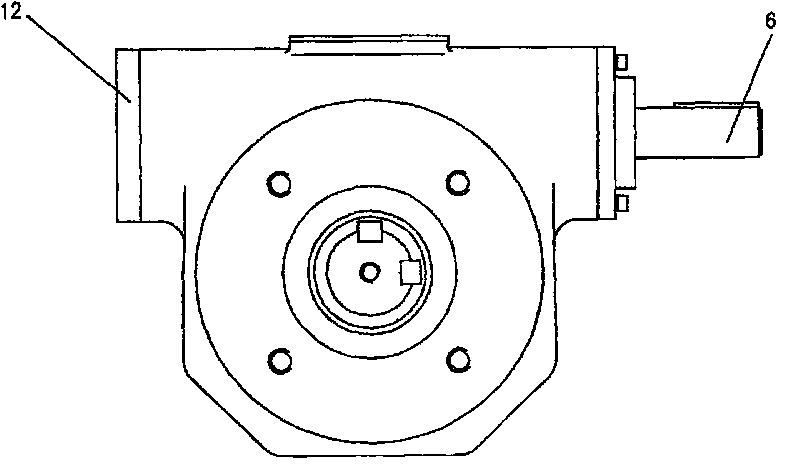

[0010] Such as figure 1 , 2 , 3, the manual device for nuclear power, including housing 1, gasket 2, bearing cap 3, O-ring 4, skeleton oil seal 5, worm 6, O-ring 7, Retaining ring 8. Bearing 9, bearing 10, bearing cover 12, gasket 13, worm gear 14, output shaft 15, O-ring 16, key 17, O-ring 18, box cover 20.

[0011] 1. Install the worm gear assembly: Install the O-ring 16 into the seal groove on the output shaft 15, install the worm gear 14 on the output shaft 15 equipped with the key 17, and pin it on the output shaft 15 with the jack 21 on;

[0012] 2. Assemble the worm gear assembly: install the O-ring 18 Box cover 20 Then put the worm gear assembly into the box body 1, the box cover 20 is buckled on the box body 1, and two horizontally installed positioning posts 19 are used for positioning, and then eight screws are used to connect the box cover 20 and the box body. 1 phase fixed;

[0013] 3. Install the worm assembly: Put the O-ring 7 into the seal groove at one end of the sc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap