Ventilation hood type microwave oven

A microwave oven and ventilation hood technology, applied in the mechanical field, can solve the problems of increasing the after-sales service burden of microwave oven manufacturers, affecting the use experience of microwave oven products, and increasing the production cost of microwave ovens, so as to avoid after-sales service burden, significant production practical significance, and prolong time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

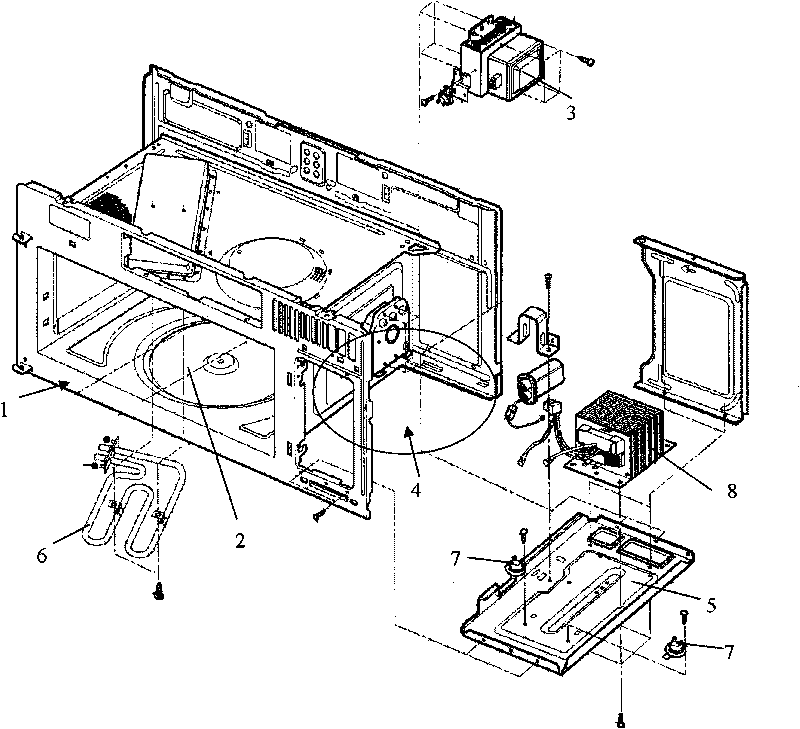

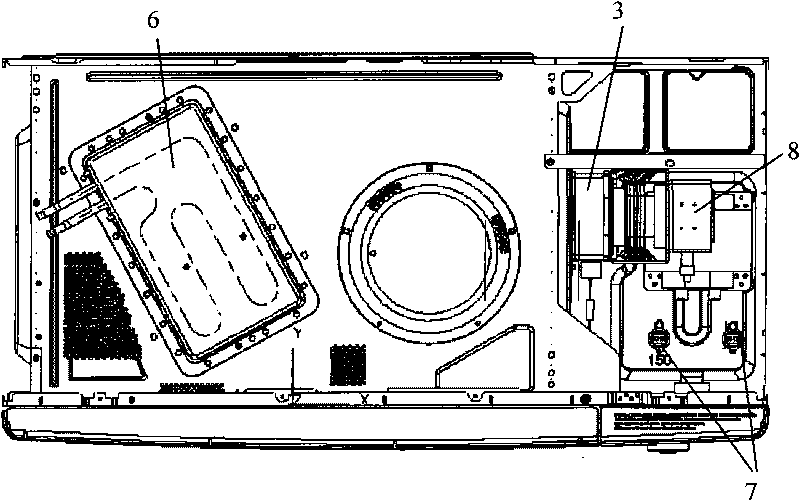

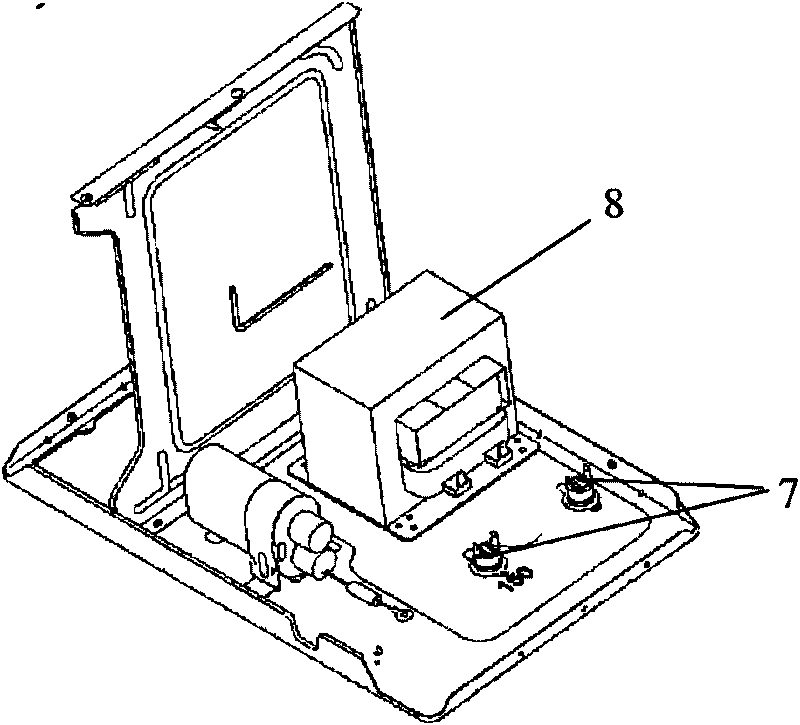

[0023] Figure 4 It is a three-dimensional schematic diagram of a partial structure of a ventilated hood microwave oven provided by the present invention, Figure 5 It is a three-dimensional schematic diagram of a thermostat of a ventilated hood microwave oven and its peripheral parts provided by the present invention.

[0024] see Figure 4 , Figure 5 , a ventilated hood type microwave oven provided by the present invention has a barbecue function, including: an external box body (not shown) constituting the external structure of the microwave oven, a furnace body 1 is provided in the external box body, and a The heating cavity 2 for cooking food has a chassis 5 on the right side of the bottom of the furnace body 1, and a magnetron 3 is in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap