Curing method for high-volume fly ash concrete

A technology with a large amount of concrete, applied in the field of concrete curing, can solve the problems of slow heat transfer speed, large heat consumption, low thermal efficiency, etc., and achieve the effect of short curing period and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

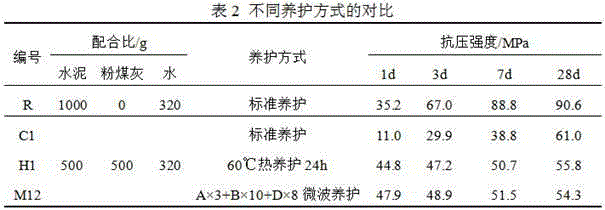

[0017] A maintenance method for large-volume fly ash concrete, the steps are as follows:

[0018] (1) Put 500g of fly ash, 500g of Portland cement clinker, and 320g of water together into a slurry mixer and mix evenly, and put the mixed concrete into a mold made of PEEK material, and its specification is 25mm× 25mm×25mm (length×width×thickness), during the molding process, attention should be paid to vibrating and compacting;

[0019] (2) Put the formed concrete together with the mold into a standard curing room for curing under standard conditions (temperature 20±1°C, humidity ≥95%);

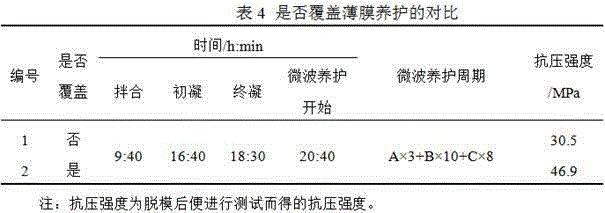

[0020] (3) 2 hours after the final setting of the concrete, cover it with a plastic film together with the mold;

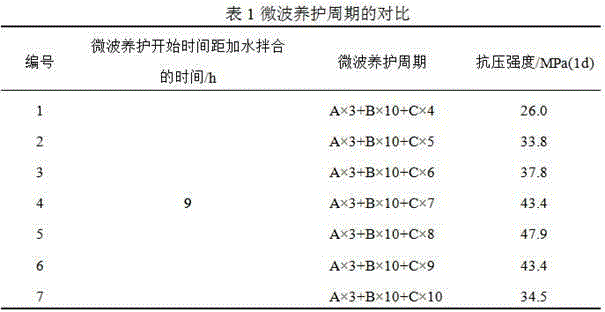

[0021] (4) Put the covered concrete into a microwave oven, and carry out microwave curing according to the different curing periods shown in Table 1; among them, A, B, and C represent: A—heat for 10 seconds and stop for 2 minutes; B—heat for 10 seconds and stop for 2 minutes; 20s, s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap