Hand-shredded beef jerky

A technology of shredded beef and beef, which is applied in the field of shredded beef jerky, can solve the problems of poor taste and texture, reduce the microbial activity of shredded beef jerky, etc., and achieve the effect of moderate spicy, delicious and mellow taste, and strong aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

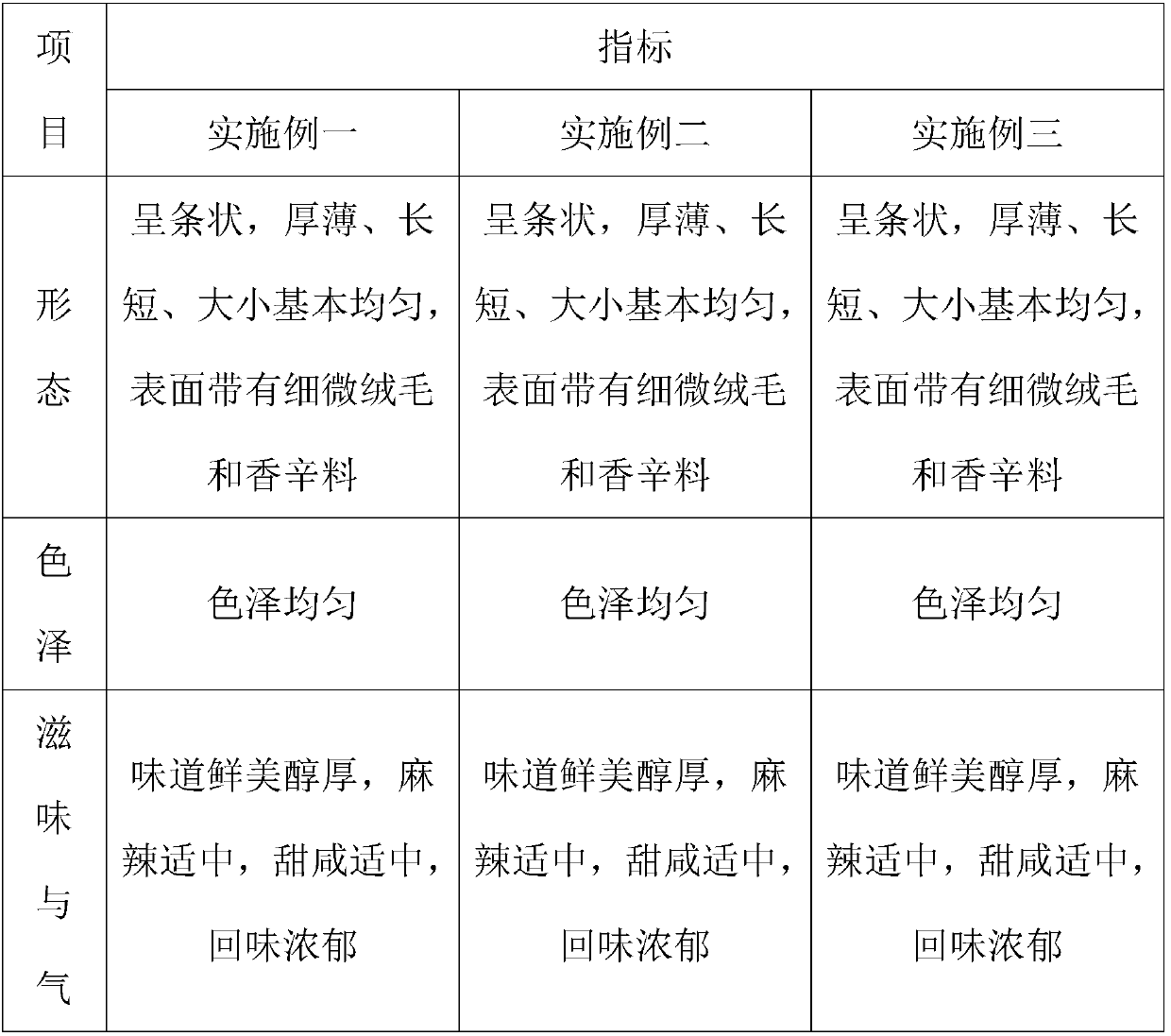

Examples

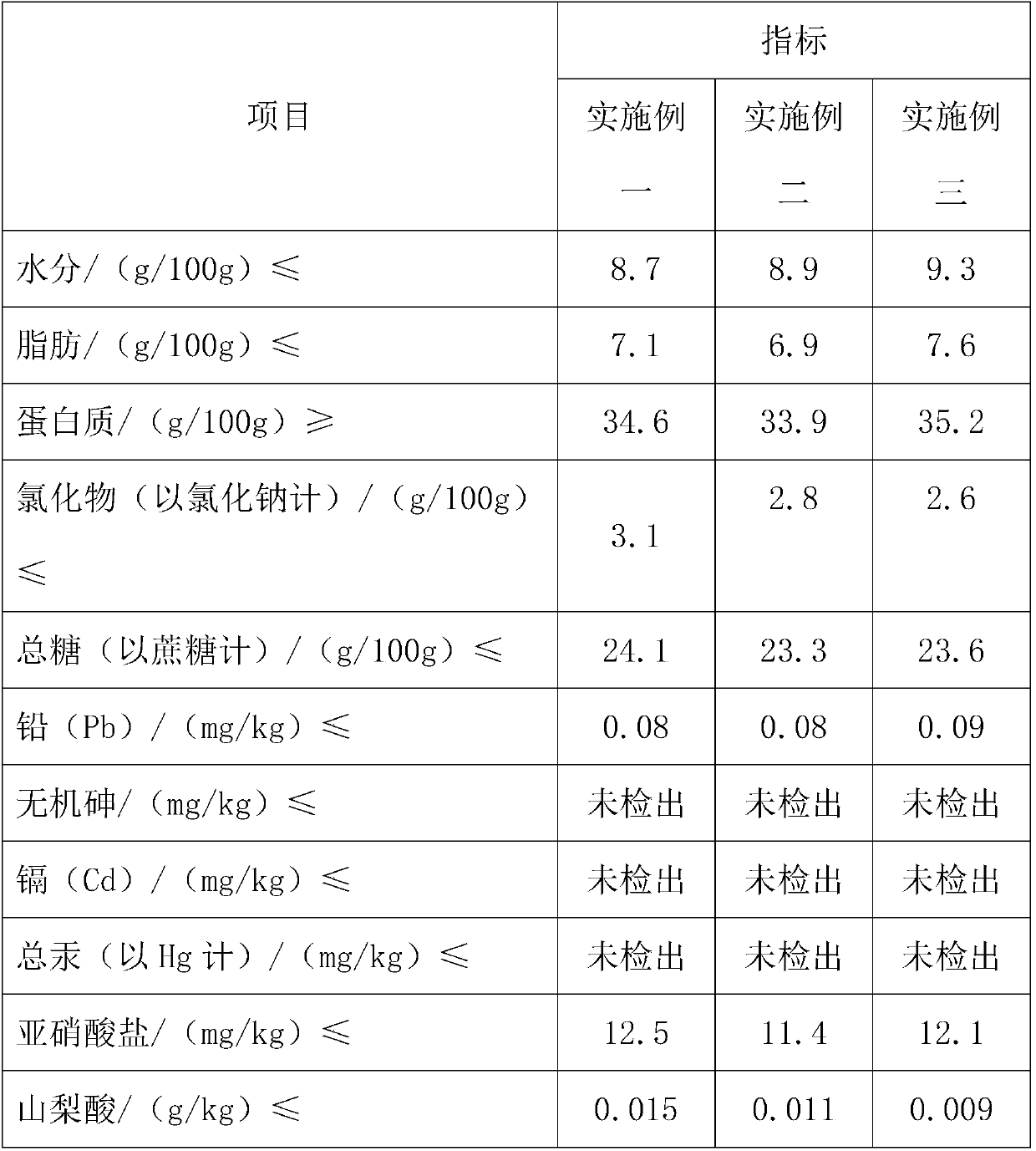

Embodiment 1

[0041] (1) Submerge 500 parts by mass of beef tendon meat in a saline solution with a mass fraction of 30% and a temperature of 30°C, take it out after immersion for 10 minutes, and wash it three times with warm boiling water at 30°C to obtain sterilized Beef Shank;

[0042](2) Immerse the sterilized beef tendon meat prepared in step (1) in boiling water at 60°C for 5 minutes, take it out, then put it in boiling water at 100°C, blanch it for 2 minutes, take it out and pour it in cold boiled water Wash 3 times, then place in blast drying oven, dry at 80°C for 60 minutes, take it out and cool to room temperature, wrap it with plastic wrap and place it in a refrigerator at 2°C for 6 hours to prepare pretreated beef tendon meat;

[0043] (3) cutting the pretreated beef tendon meat obtained in step (2) into beef strips with a length of 100 mm, a width of 20 mm and a thickness of 20 mm along the lines of the muscle;

[0044] (4) Put the beef barcodes prepared in step (3) into a row an

Embodiment 2

[0055] (1) Submerge 500 parts by mass of beef tendon meat in a saline solution with a mass fraction of 35% and a temperature of 37°C, take it out after immersion for 15 minutes, and wash it with warm boiling water at 35°C for 4 times to obtain sterilized Beef Shank;

[0056] (2) Immerse the sterilized beef tendon meat prepared in step (1) in boiling water at 70°C for 8 minutes, then put it in boiling water at 100°C, blanch for 3 minutes, take it out and pour it in cold boiled water Wash 4 times, then place in blast drying oven, dry at 80°C for 80 minutes, take it out and cool to room temperature, wrap it with plastic wrap and place it in a refrigerator at 4°C for 8 hours to prepare pretreated beef tendon meat;

[0057] (3) cutting the pretreated beef tendon meat obtained in step (2) along the grain of the muscle into beef strips with a length of 150mm, a width of 25mm, and a thickness of 25mm;

[0058] (4) Put the beef barcodes obtained in step (3) into a row and roll them with

Embodiment 3

[0069] (1) Immerse 500 parts by mass of beef tendon meat in a saline solution with a mass fraction of 40% and a temperature of 40°C, take it out after immersion for 20 minutes, wash it with 40°C warm water for 5 times, and obtain sterilized Beef Shank;

[0070] (2) Immerse the sterilized beef tendon meat prepared in step (1) in boiling water at 80°C for 10 minutes, take it out, then put it in boiling water at 100°C, blanch it for 5 minutes, take it out and pour it in cold boiled water Wash 5 times, then place in blast drying oven, dry at 80°C for 90 minutes, take it out and cool to room temperature, wrap it with plastic wrap and place it in a refrigerator at 8°C for 10 hours to prepare pretreated beef tendon;

[0071] (3) cutting the pretreated beef tendon meat obtained in step (2) into beef strips with a length of 200 mm, a width of 30 mm and a thickness of 30 mm along the lines of the muscles;

[0072] (4) Put the beef barcodes obtained in step (3) into a row and roll them wit

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap