Rock climbing plate resin point seat cover and manufacturing method thereof

A production method and technology of rock climbing boards, applied in the direction of sports accessories, etc., can solve the problems of easy rust and oxidation, difficult replacement, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

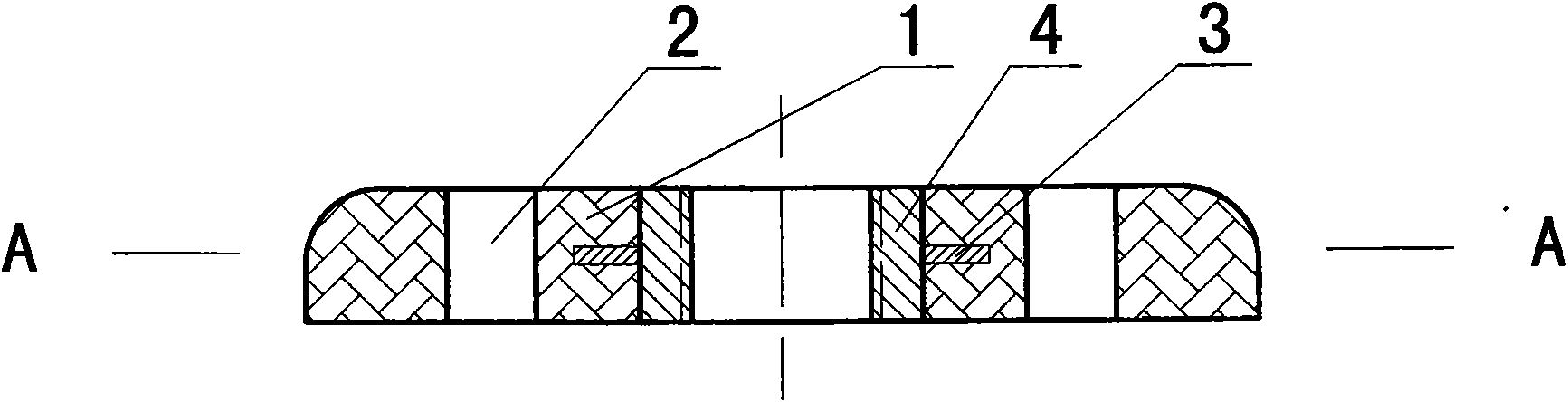

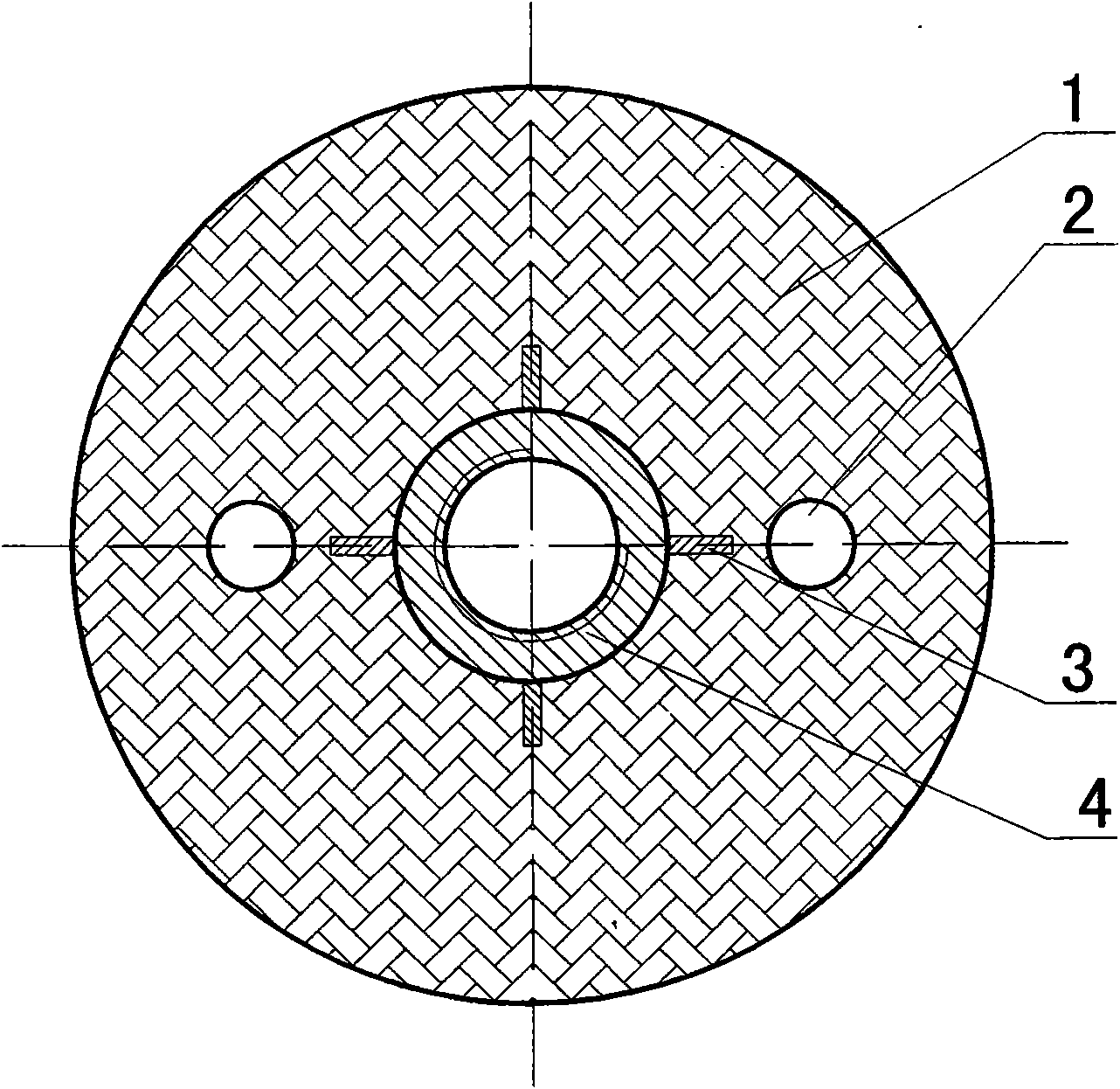

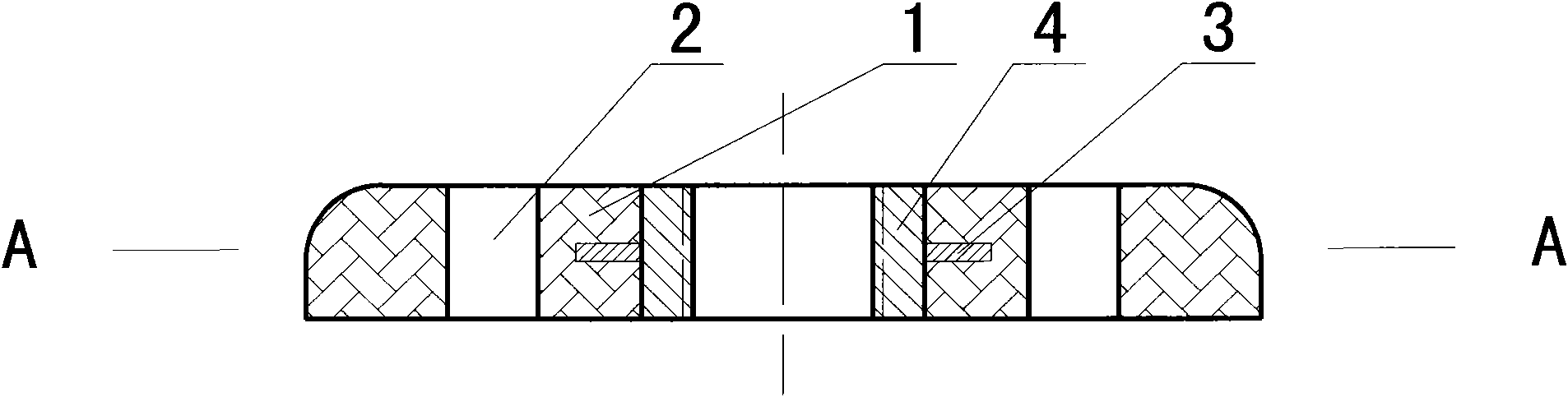

[0007] Embodiment 1: A rock climbing board resin point seat cover and its manufacturing method, 4 claws (3) are fixed on the nut (4), it is poured in the resin (1) in the mold, in the resin (1) Anti-slip holes (2) are symmetrically opened on both sides of the end face, and the production method is to set the nut (4) with the claw (3) on the silica gel column in the mold, sprinkle quartz sand evenly on the bottom of the mold, and pour resin ( 1) Sprinkle quartz sand evenly on the surface of the resin (1) during initial setting, solidify and demould, and symmetrically open anti-slip holes (2) on both sides of the end face of the resin (1).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap