High-temperature steam recoverer

A technology of high-temperature steam and recycler, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve the problems of high energy consumption and high cost of polyester staple fiber heat-setting equipment, and achieve simple structure and economical use Cost, effect of using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

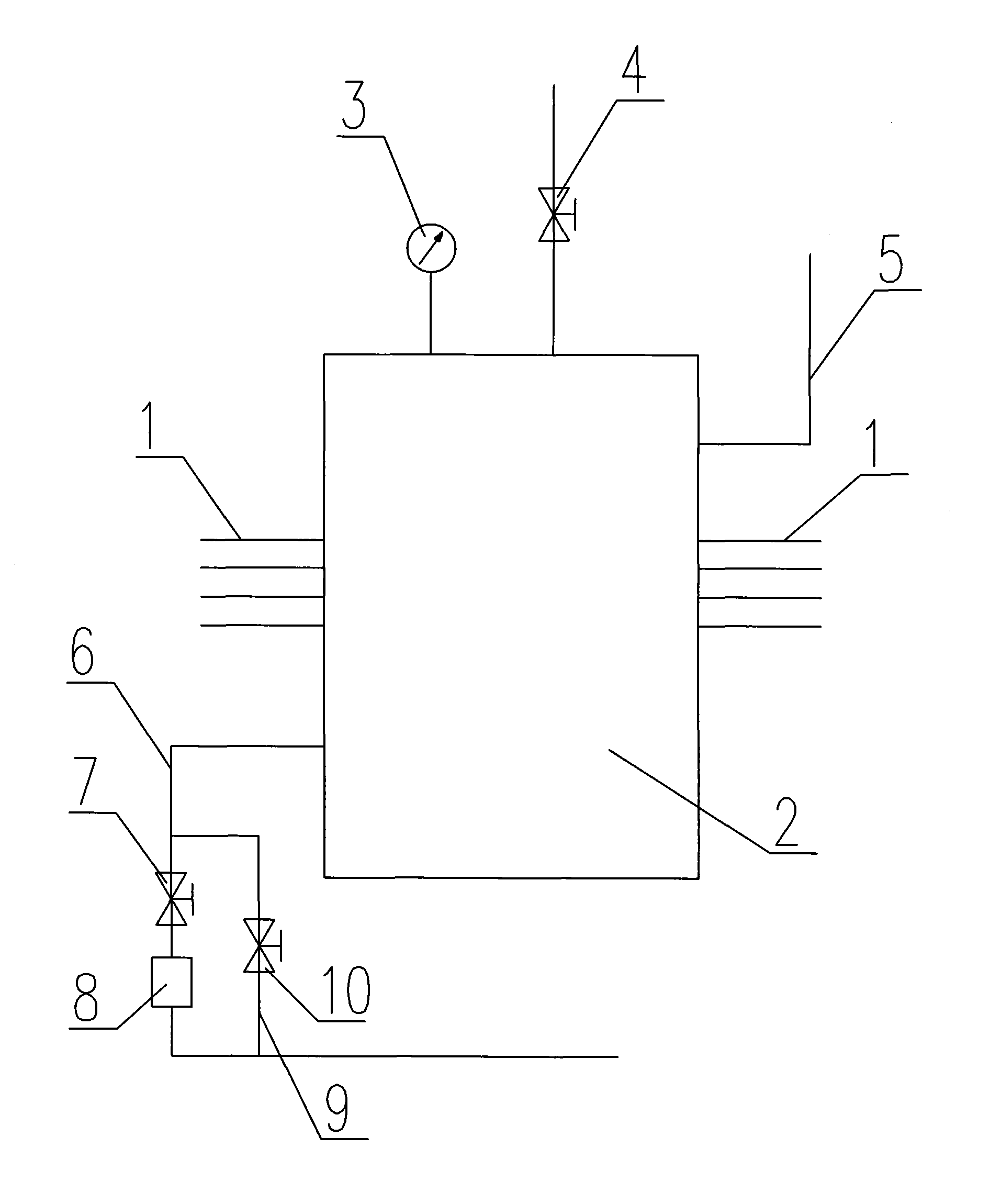

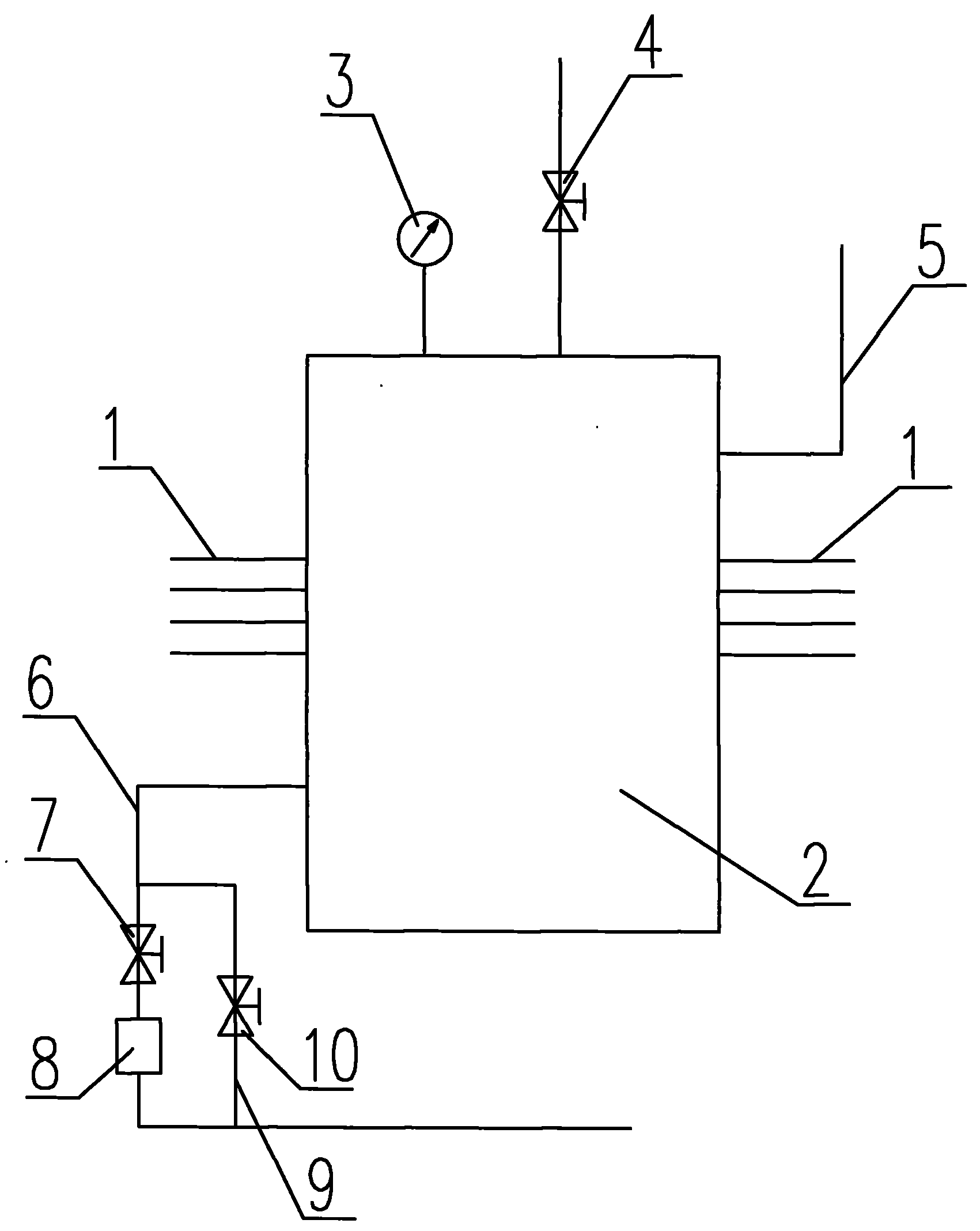

[0010] like figure 1 As shown, the high-temperature steam recovery device includes: a plurality of exhaust gas recovery branch pipes 1 connected to the exhaust gas outlet on the polyester staple fiber heat-setting equipment, and the other ends of the exhaust gas recovery branch pipes 1 are respectively connected with the gas storage tank 2, in the gas storage tank 2 A pressure gauge 3 and a safety valve 4 are respectively set at the upper end of the gas storage tank, which can ensure the safe operation of the gas storage tank. The high-temperature steam in the gas storage tank 2 is discharged through the high-temperature steam outlet pipe 5, and the gas storage tank 2 is connected with the drain pipe 6. The pipe 6 is provided with a manual valve 7 and an automatic steam trap 8 .

[0011] In this embodiment, the drain pipe 6 is also provided with a backup branch pipe 9 , and the backup branch pipe 9 is provided with a branch pipe manual valve 10 .

[0012] The high-temperature wa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap