Electric mosquito swatter with net surface power-off protection device

A power-off protection device and an electric-killing technology, which are applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve problems such as concerns affecting the safety of electric mosquito-killing swatters, increased power consumption of products, and hidden safety hazards, etc. Achieve the effect of improving service life, improving safety, and eliminating safety concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

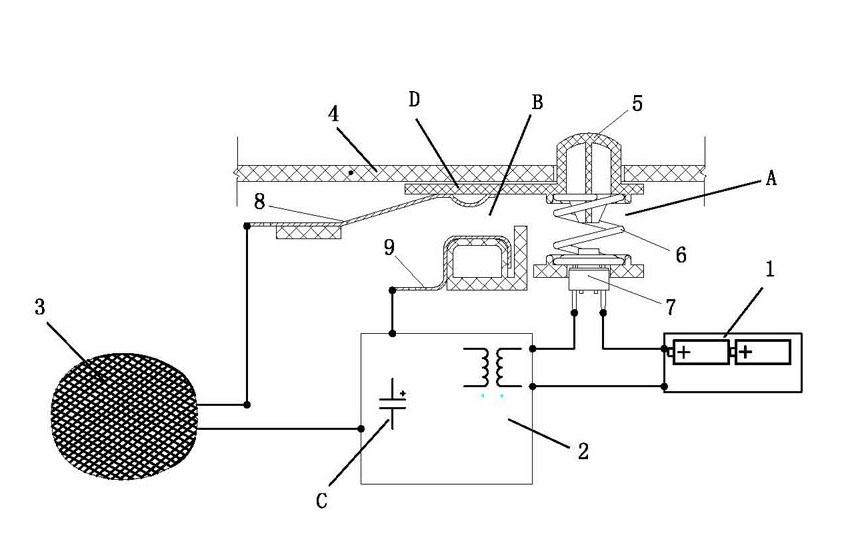

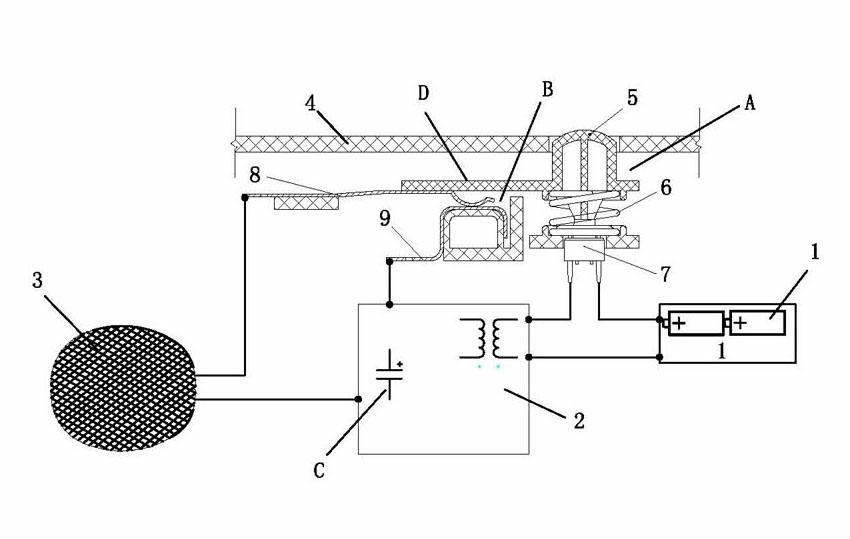

[0021] Example 1: as Figure 1 to Figure 2 As shown in the figure, an electric mosquito killing swatter of a mesh surface power failure protection device includes a mosquito killing net 3, a handle 4, a booster circuit 2 and a power supply 1, and the power supply 1 provides sufficient voltage for the mosquito killing net 3 through the booster circuit 2, A control switch A is connected in series between the power supply 1 and the booster circuit 2 , and it is characterized in that a manually controlled network surface power-off protection device B is connected in series between the booster circuit 2 and the mosquito net 3 .

[0022] The above-mentioned mesh surface power failure protection device B is a normally open contact switch, and the normally open contact switch is connected with the control switch A through the linkage D; the normally open contact switch can be composed of two spring sheets 8 and 9, The outer ends of the two spring sheets 8 and 9 are respectively connected

Example Embodiment

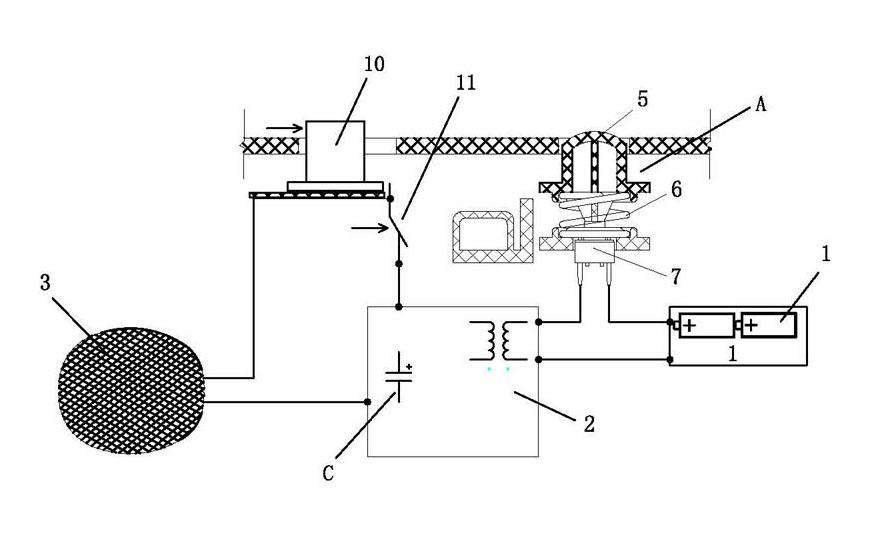

[0026] Embodiment 2: as image 3 As shown, this embodiment is similar to the above-mentioned first embodiment, the difference is only: the mesh surface power-off protection device B is an independent manual control switch, and the control key 10 of the manual control switch is arranged on the surface of the handle 4 shell, The independent manual control switch also includes a normally closed switch 11. The normally closed switch 11 is connected in series between the booster circuit 2 and the mosquito net 3. The normally closed switch 11 is connected to the control key 10, and the control key 10 is not automatically reset. That is, after the control key 10 is toggled, the normally closed switch 11 can be kept in the "normally open state" for a long time (toggle it again, it is in the normally closed state, and the control key 10 itself cannot be reset automatically).

[0027] Of course, the structure of the second embodiment above can also be in the form of a "control switch" (not

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap