Anti-corona ball used for squirrel-cage rigid jumper device

A technology of rigid jumpers and anti-corona balls, which is applied in overhead installation, cable installation, electrical components, etc., can solve problems such as limited improvement effects, and achieve the effects of simple structure, suppression of corona discharge, and light material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

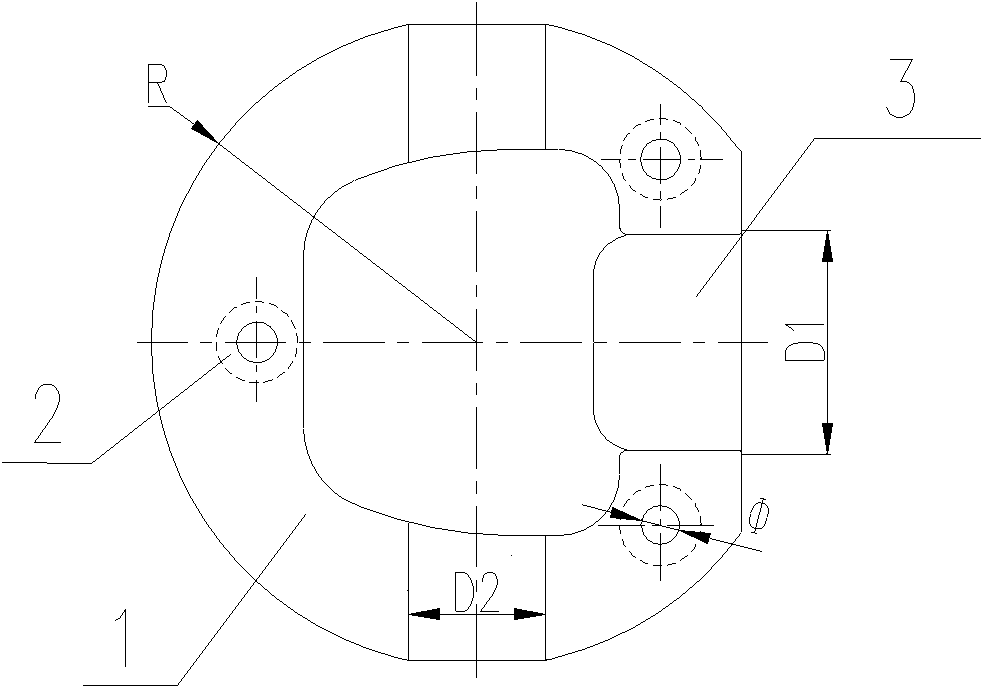

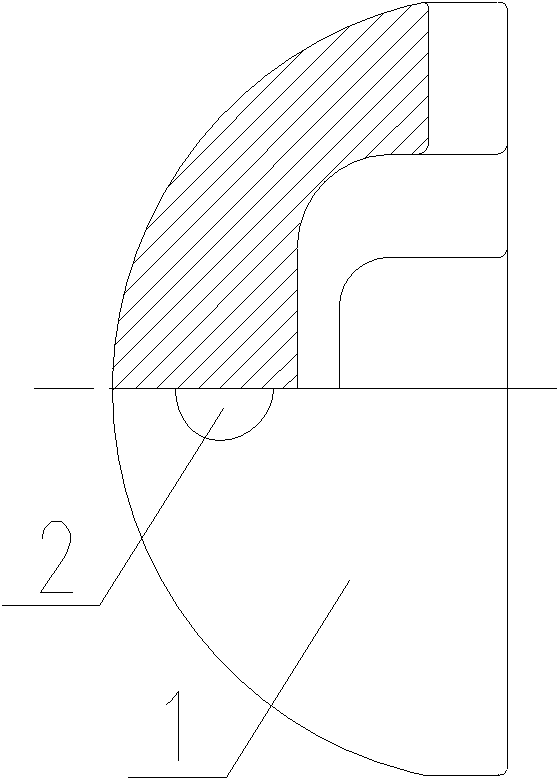

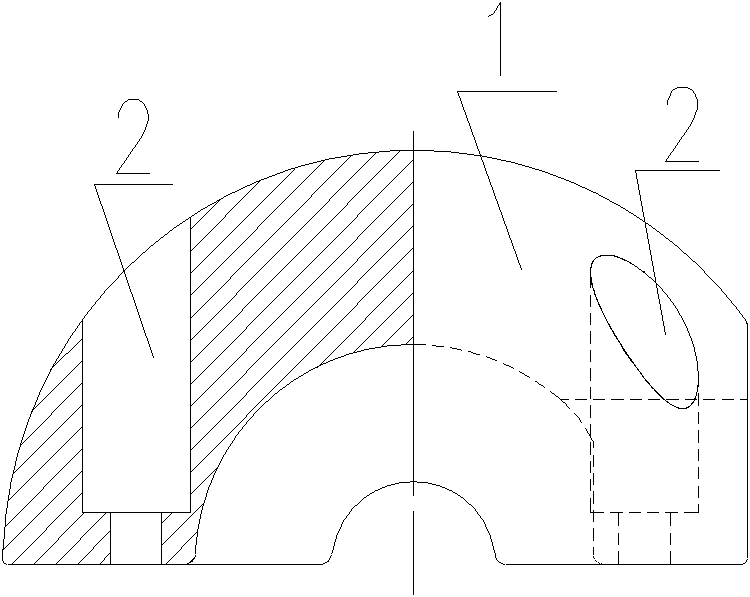

[0033] as attached figure 1 As shown, the overall schematic diagram of the anti-sickness ball, the spherical shell, the interior is hollow, and is made of aluminum alloy material, and the anti-sickness ball can be divided into two parts: a hemispherical shell 1 and a bolt 2 . The side view and cross-sectional view of the anti-halo ball (hemisphere) are as follows: figure 2 As shown, the top view and section view of the anti-halo ball (hemisphere) are as follows image 3 shown.

[0034] The radius R of the outer surface of the hemispherical shell 1 is not less than 50mm, and the internal size is related to the size of the matching spacer, wherein the hollow part is larger than the size of the spacer clamp head. The diameter D1 of the inner surface of the mounting hole 3 should be larger than the size of the arm of the spacer clamp to ensure that the anti-halation ball can completely shield the head of the clamp without exerting additional pressure on the arm of the clamp.

[0

Embodiment 2

[0038] The preparation material of anti-halation ball of the present invention can select ZL-102 aluminum alloy material for use, about ZL-102 aluminum alloy material, introduce as follows:

[0039] Material name: ZAlSi12

[0040] Alloy code: ZL102

[0041] Standard: GB / T 1173-1995

[0042] Features and scope of application:

[0043] It cannot be strengthened by heat treatment. The alloy has excellent casting performance, no hot cracking and loose tendency, and high air tightness. It has low density and good corrosion resistance. It can be used in environments subject to atmospheric and seawater corrosion, and can withstand the corrosion of concentrated nitric acid and hydrogen peroxide in industrial atmospheres. It also has good welding performance. However, the alloy has low mechanical properties, poor heat resistance and machinability.

[0044] chemical composition:

[0045] Silicon Si: 10.0-13.0

[0046] Aluminum Al: balance

[0047] Iron (sand casting): 0.000~0.700

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap