Z-shaft independent controller for planar laser cutting machine

A plane laser and cutting machine technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems affecting the use of plane laser cutting machine tools, the complex structure of the three-axis motion control card, and the poor reliability of the machine tool movement. Simple, highly reliable movement and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

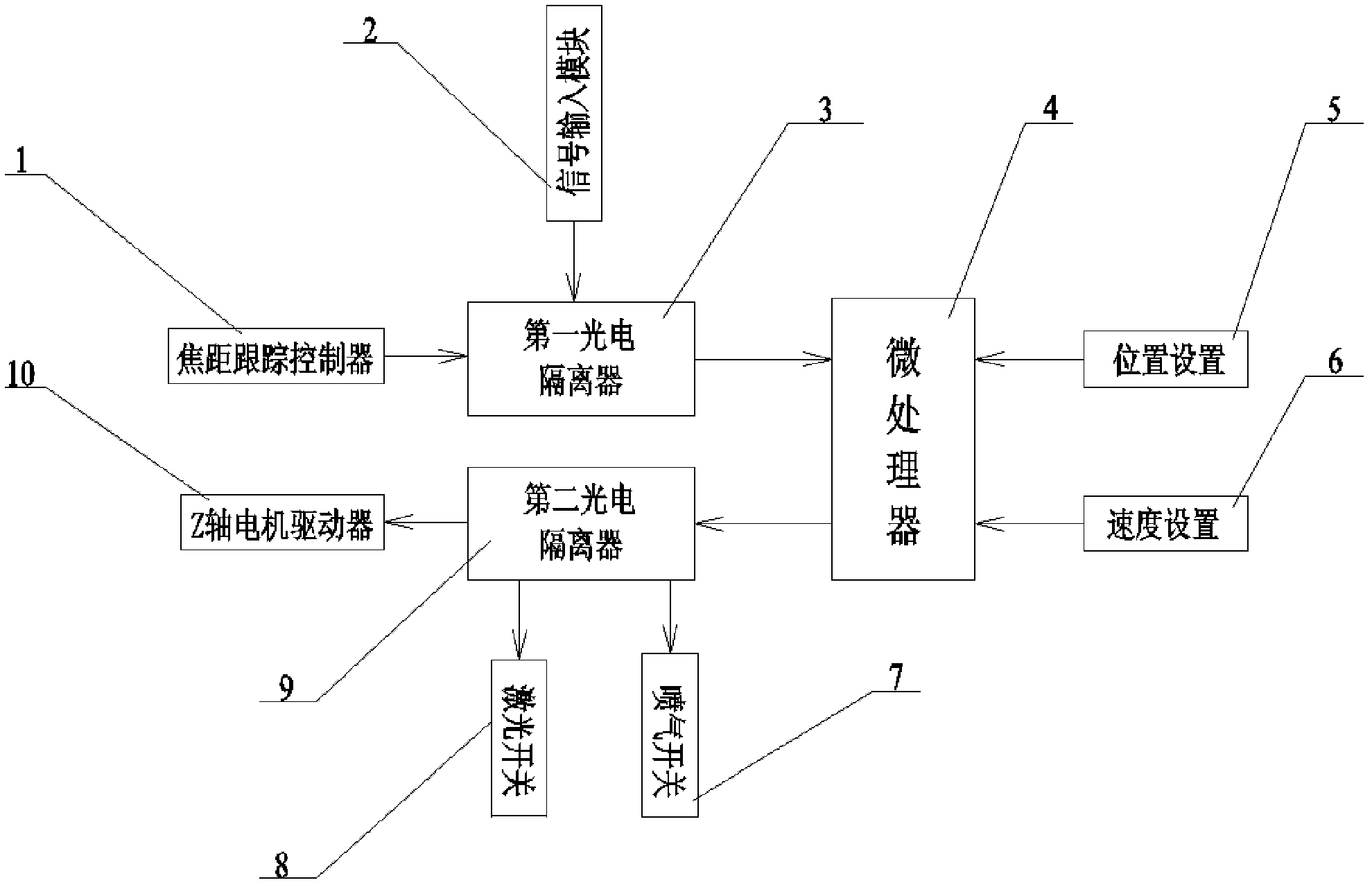

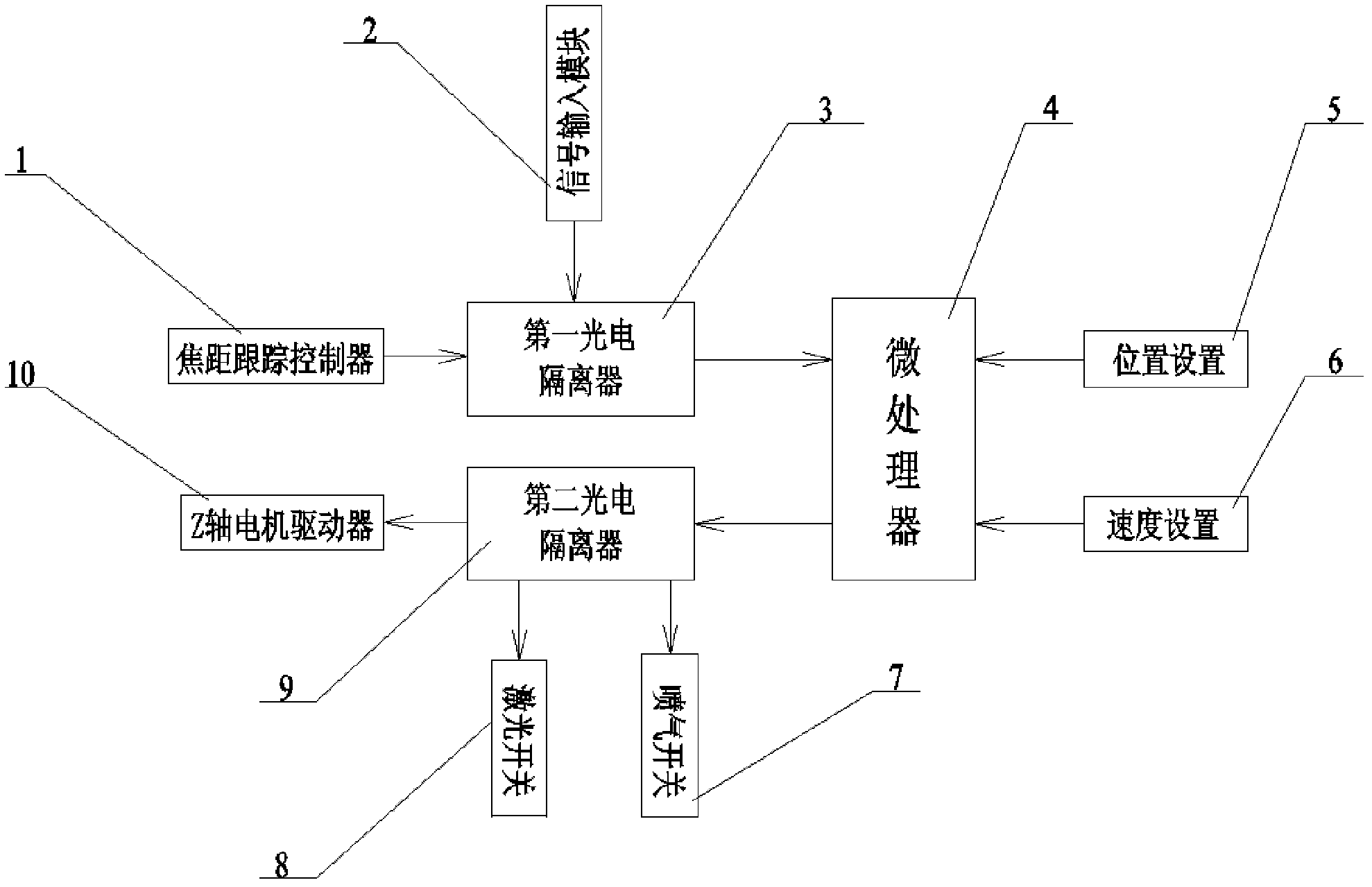

[0011] Such as figure 1 As shown: the present invention includes a focus tracking controller 1, a signal input module 2, a first photoelectric isolator 3, a microprocessor 4, a position setting module 5, a speed setting module 6, an air jet switch 7, a laser switch 8, a second photoelectric The isolator 9 and the Z-axis motor driver 10.

[0012] Such as figure 1 Shown: In order to reduce the complexity of the control controller of the plane laser cutting machine tool and improve the control accuracy, the Z-axis control mode of the machine tool is independent, and the Z-axis control no longer occupies the motion control resources of the machine tool. In order to be able to control the Z-axis, the Z-axis independent controller includes a microprocessor 4, which may be a single-chip microcomputer, ARM (Advanced RISC Machines) or other processing chips. The input e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap