Transformer oil tank

A technology for a transformer oil tank and a box body is applied in the field of transformer oil tanks, which can solve the problems of difficult assembly and transportation, unsightly appearance, and difficult maintenance, and achieve the effects of simple and lightweight structure, good heat dissipation performance and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The present invention will be further explained below in conjunction with the drawings.

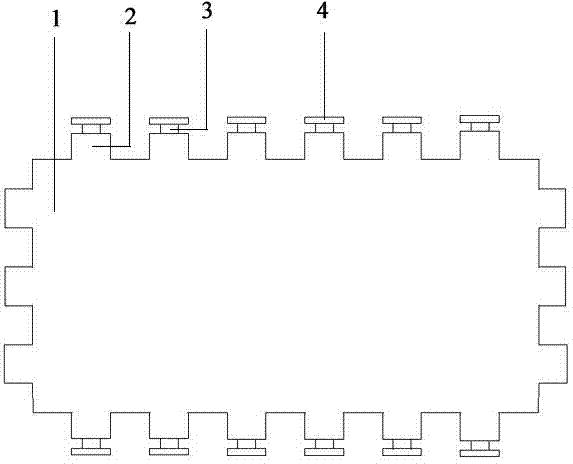

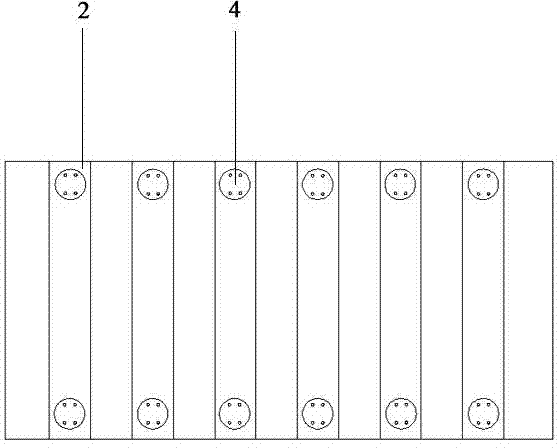

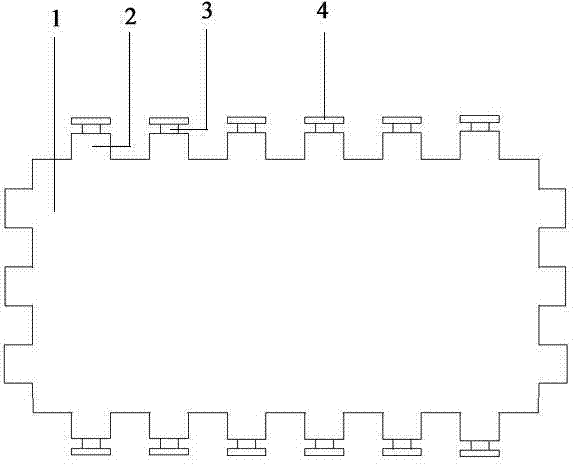

[0012] Such as figure 1 , 2 As shown, the tank body 1 is a bell-jar type, and a plurality of convex corrugations 2 parallel to each other are arranged on the wall of the tank. The wall of the tank is formed by one-step corrugation, and the upper and lower ends of the corrugations 2 on the two opposite long end faces Each nozzle 3 is provided with a flange 4 outside each nozzle 3, the flange 4 has a slotted structure and a limiting structure, and the connection between the nozzle 3 and the flange 4 is provided with a nitrile rubber gasket ( Not shown in the figure).

[0013] The wall of the corrugated forming box is made of a large folding machine, which eliminates the use of reinforcing iron, reinforcing ribs or reinforcing plates. The structure is simple and light, reduces welding seams, saves welding man-hours, and is more conducive to paint coating. It is also easier to repair leaks. T

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap