Tea tree slow-release fertilizer and preparation technology thereof

A tea tree and fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of weak slow-release (controlled release) ability and no slow-release (controlled release) ability of white pollution, so as to reduce the dosage and improve the packaging sealing rate and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The wrapping of embodiment 1 inorganic fertilizer

[0027] Take 35 kilograms of urea, 50 kilograms of diammonium phosphate, 10 kilograms of potassium chloride, 1 kilogram of zinc sulfate heptahydrate, and 1 kilogram of magnesium sulfate heptahydrate; Made into particles with a diameter of about 0.5mm, that is, unwrapped fertilizer.

[0028] Take 0.5 kg of BergaFat (BergaFat) HTL316 (available from Huixingao Animal Husbandry Co., Ltd., Nanning, Guangxi) and melt it in an oven at 60 ° C, and then use a fluidized granulation coating machine to spray it all evenly onto 9.5 kg of the above-prepared granules Inorganic fertilizer 1 is obtained by forming an encapsulation layer on the surface of the substrate; another 2 kg of BergaFat HTL316 (available from Huixingao Animal Husbandry Co., Ltd., Nanning, Guangxi) is melted in an oven at 60°C, and then used in a fluidized granulation bag The clothes machine uniformly sprays all of them on the surface of 8 kg of the above-mentioned

Embodiment 2

[0029] Embodiment 2 The wrapping of the fertilizer containing fulvic acid

[0030] Take 28 kg of ammonium chloride, 40 kg of diammonium phosphate, 8 kg of potassium chloride, 1 kg of zinc sulfate heptahydrate, and 1 kg of magnesium sulfate heptahydrate, mix well, then add 20 kg of fulvic acid and 2 kg of water, mix After uniformity, crush and sieve to make granules with a diameter of about 0.5mm.

[0031] Take 0.5 kg of BergaFat (BergaFat) HTL316 (available from Huixingao Animal Husbandry Co., Ltd., Nanning, Guangxi) and melt it in an oven at 60 ° C, and then use a fluidized granulation coating machine to spray it all evenly onto 9.5 kg of the above-prepared granules A coating layer is formed on the surface of the fertilizer, that is, a fertilizer containing fulvic acid is obtained.

Embodiment 3

[0032] The dissolution rate test of embodiment 3 package fertilizer

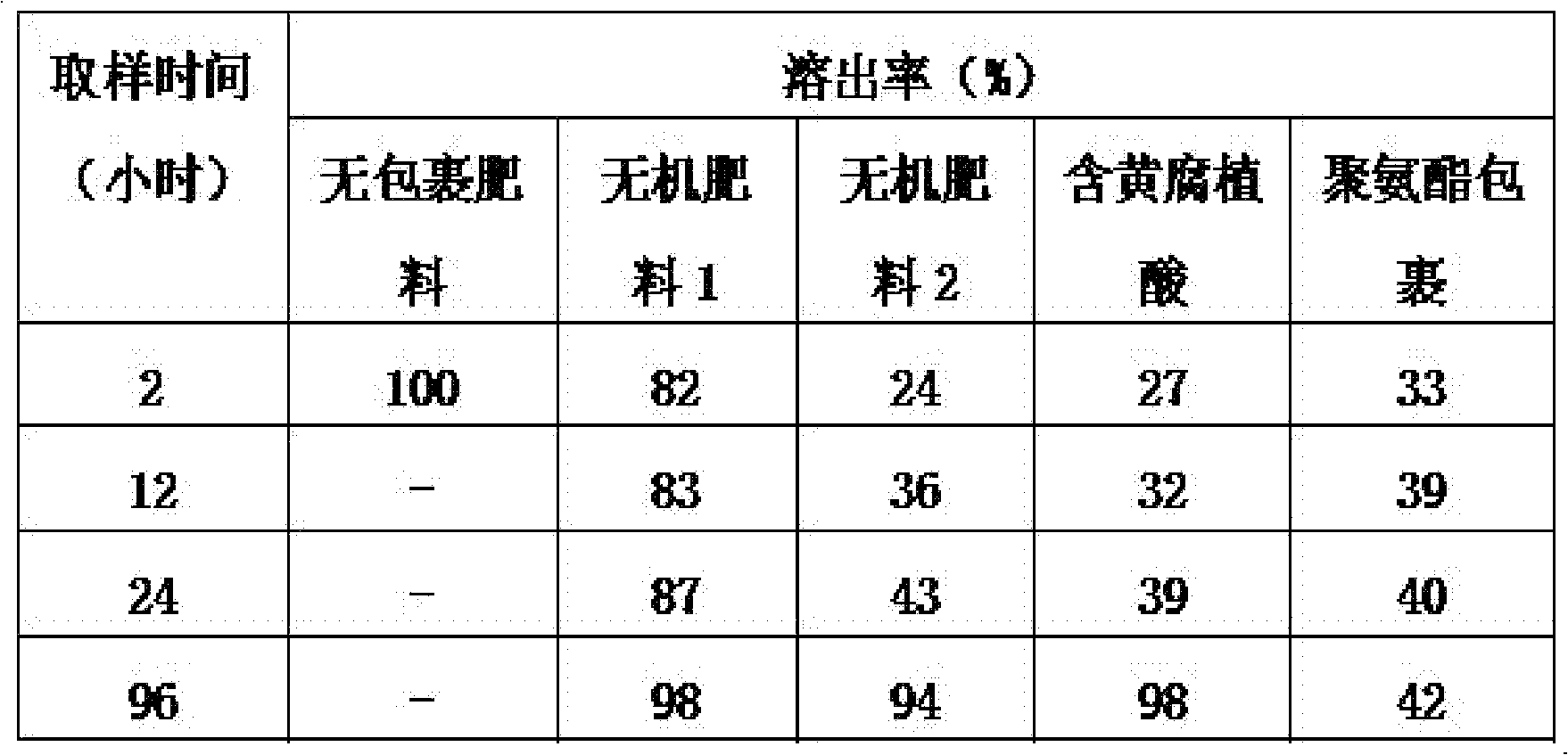

[0033] Get the inorganic fertilizer 1, inorganic fertilizer 2 and the fertilizer containing fulvic acid prepared in Examples 1 and 2, and take the non-wrapped fertilizer prepared in Example 1 and the fertilizer wrapped with polyurethane resin as a contrast, immerse in clear water, in different Timely water samples were taken to detect the dissolution rate of fertilizers, and the results are shown in the table below:

[0034]

[0035] The unwrapped fertilizer dissolved almost immediately, indicating that it could not have a slow-release effect; the fertilizer wrapped with polyurethane was dissolved at the beginning except for the fertilizer particles that were not wrapped and sealed (encapsulated), and then rarely released fertilizer, and the dissolution efficiency was too low; The encapsulation efficiency of fertilizer 1 is very low, causing a large amount of fertilizer to dissolve at the beginning, but the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap