Method for preparing absorbing material by using lakebed sludge

An adsorption material and lake bottom sludge technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of surfactant toxicity, single adsorption object, cumbersome production process, etc. , to achieve the effect of excellent adsorption performance, extensive application conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

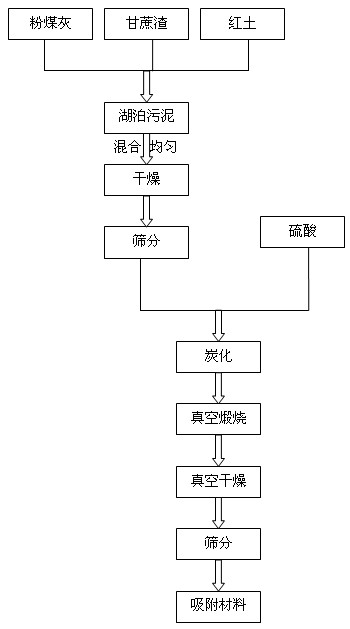

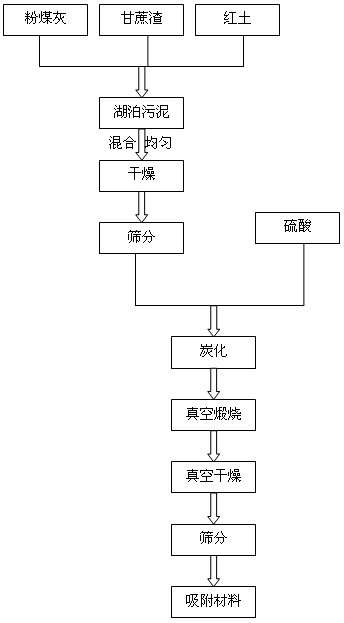

[0022] Embodiment 1: the method for preparing adsorption material from lake bottom sludge, concrete operations are as follows:

[0023] (1) Mix 12% by weight of fly ash, 37% by weight of bagasse, 6% by weight of Yunnan Dongchuan red soil, and 45% by weight of bottom sludge of Yunnan Yilong Lake. After stirring evenly, stack them at room temperature , measure the water content once every 12 hours, until the water content of the sludge mixture drops to 30% after 84 hours, pass through a 65-mesh sieve to obtain a granular lake sludge mixture;

[0024] (2) Add sulfuric acid with 10% by weight of the mixture (the concentration of sulfuric acid is 76% by weight) to the mixture. After mixing evenly, put the mixture into a tunnel kiln for carbonization at 80°C for 3 hours, and the product after the above treatment Move it into a vacuum calciner at 200°C for 7 hours in vacuum until the remaining sulfuric acid reacts completely, dry it in vacuum, pass through a 200-mesh sieve, take the

Embodiment 2

[0026] Embodiment 2: the method for preparing adsorption material from lake bottom sludge, concrete operations are as follows:

[0027] (1) Mix 30% by weight of fly ash, 15% by weight of bagasse, 5% by weight of Yunnan Dongchuan red soil, and 50% by weight of bottom sludge of Yunnan Yilong Lake. After stirring evenly, stack them at room temperature , measure the water content every 12 hours, and after 72 hours, the water content of the sludge mixture drops to 35%, and pass through an 80-mesh sieve to obtain a granular lake sludge mixture;

[0028] (2) Add sulfuric acid of 30% by weight of the mixture to the mixture (the mass percent concentration of sulfuric acid is 20%), and after mixing evenly, put the mixture into a tunnel kiln for carbonization at 40°C for 10 hours, and move the product after the above treatment into Vacuum calcining at 150°C for 5 hours in a vacuum calciner until the remaining concentrated sulfuric acid reacts completely, vacuum drying, passing through a 50-

Embodiment 3

[0030] Embodiment 3: the method for preparing adsorption material from lake bottom sludge, concrete operations are as follows:

[0031] (1) Mix 30% by weight of fly ash, 40% by weight of bagasse, 10% by weight of Yunnan Dongchuan red soil, and 20% by weight of Dianchi lake bottom sludge. After stirring evenly, stack them at room temperature. Measure the moisture content once every 12 hours, and after 108 hours, the moisture content of the sludge mixture drops to 25%, and passes through a 400-mesh sieve to obtain a granular lake sludge mixture;

[0032] (2) Add sulfuric acid of 2% by weight of the mixture to the mixture (the mass percent concentration of sulfuric acid is 98%), and after mixing evenly, put the mixture into a tunnel kiln for carbonization at 150°C for 2 hours, and move the product after the above treatment into Vacuum calcining at 300°C for 0.5h in a vacuum calciner until the remaining concentrated sulfuric acid reacts completely, then vacuum-dry, pass through a 400

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap