Portable electronic device

An electronic device and portable technology, which is applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve problems such as time-consuming, damage, and waste of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

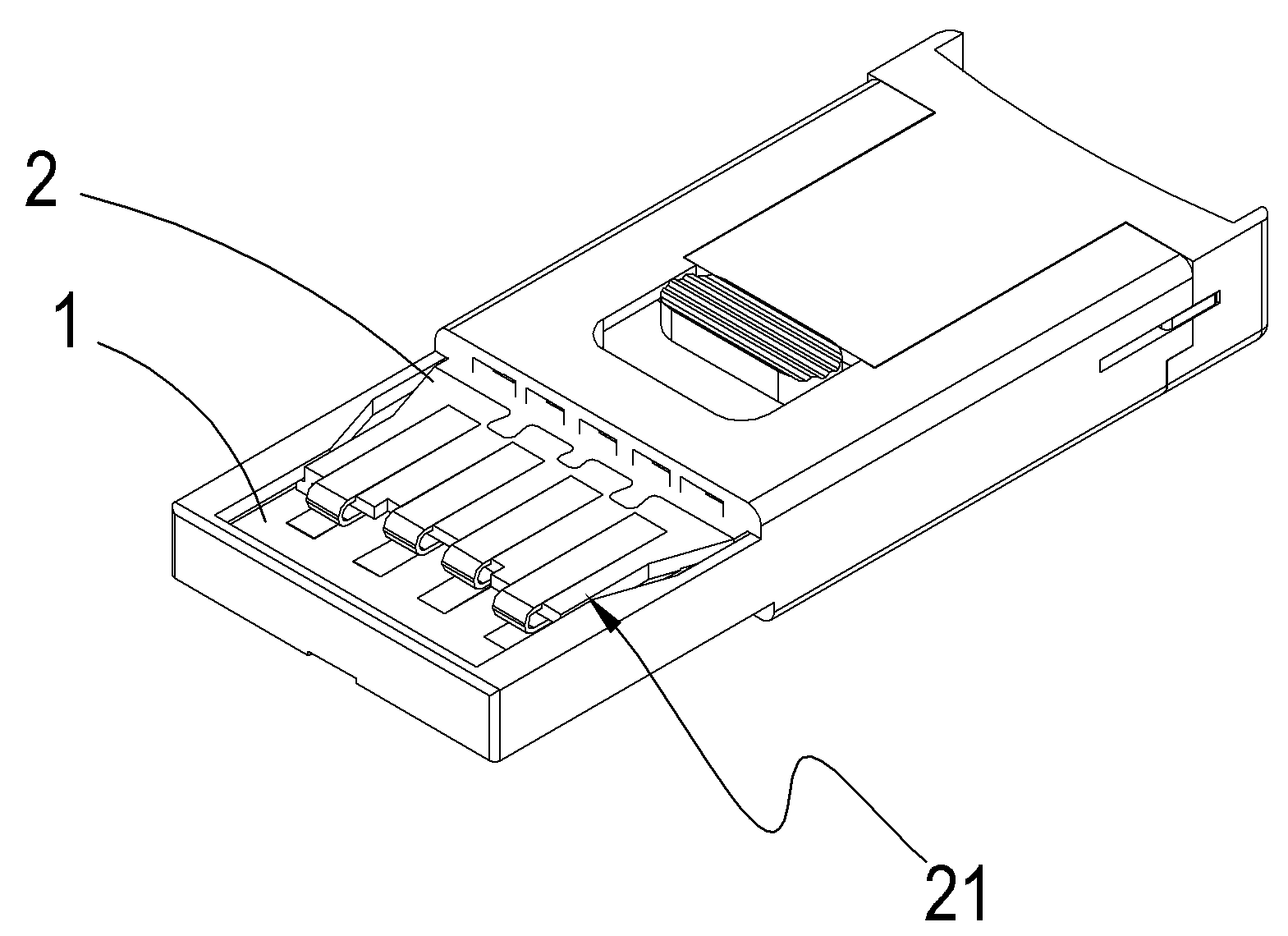

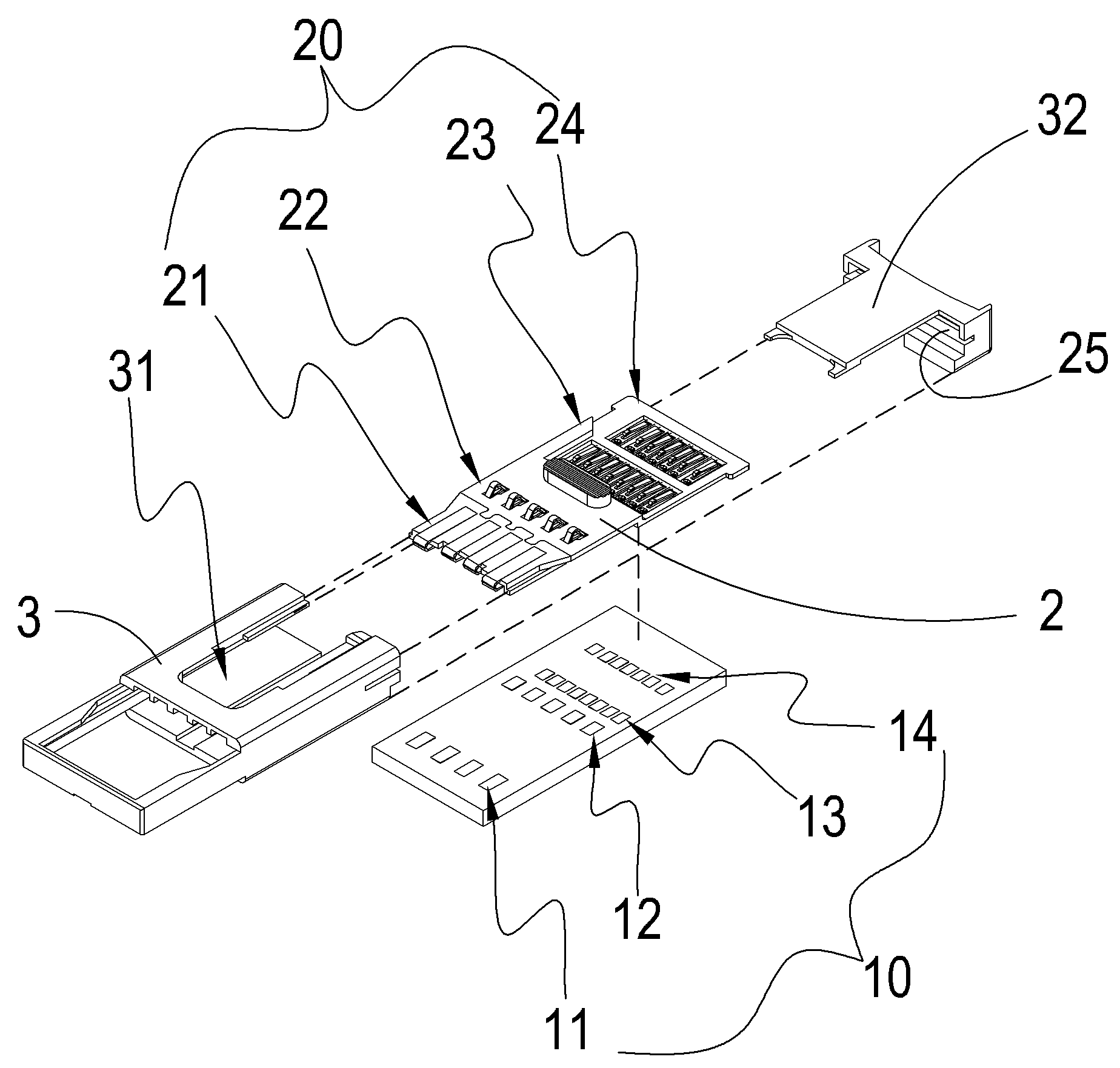

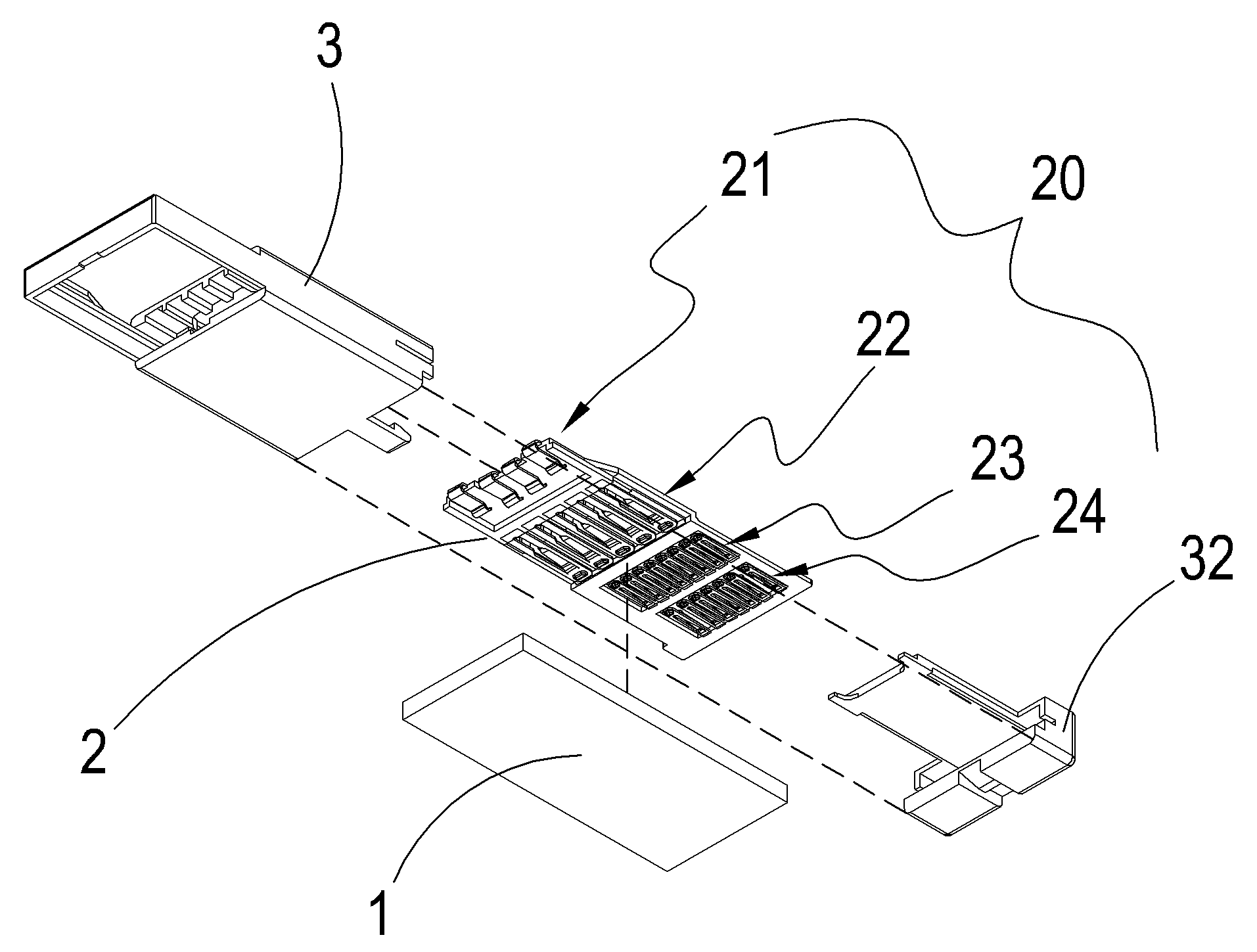

[0022] as attached figure 1 to attach image 3 As shown, it is a perspective view and an exploded view of the first preferred embodiment of the present invention. It can be clearly seen from the figure that the portable electronic device of the present invention includes:

[0023] An electronic module 1, at least one electronic module metal conductor group 10 is provided at one side of the electronic module 1, and the electronic module metal conductor group 10 includes a first metal conductor group 11, a metal conductor group 11 located on the first metal conductor group 11 The second metal conductor group 12, a third metal conductor group 13 located on the side of the second metal conductor group 12 away from the first metal conductor group 11, and a third metal conductor group 13 located on the side away from the second metal conductor group 12 The fourth metal conductor set 14 on the side;

[0024] At least one insulating colloid 2 is slid on the electronic module 1. The ins

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap