Cast iron pillar for motor

A pig iron and iron column technology, applied in the field of magnetic circuit pig iron column parts, can solve problems such as effective magnetic flux slump, eddy current loss prominent, output reduction, etc., and achieve the effect of simple and reasonable structure, increased output power, and small external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the embodiment shown in accompanying drawing below:

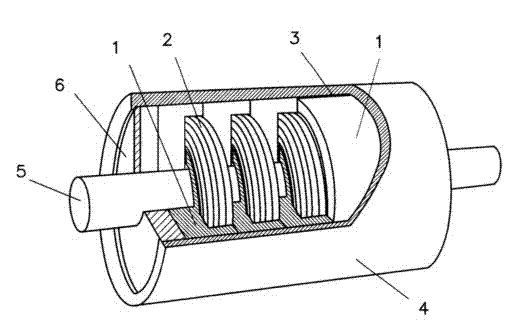

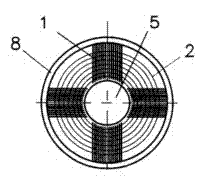

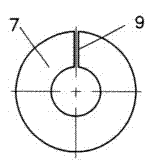

[0023] See attached picture. figure 1 Shown is a cylindrical linear motor composed of cast iron columns of the motor. The mover 5 is installed in the stator 4, wherein the pig iron is composed of pig iron columns, and the pig iron columns are assembled by unit integral sections with slits or slots 3 cast iron column. The whole pig iron column section is processed with ferromagnetic material, and there are winding cavity warning for installing winding and slot holes for lead wire and mechanical fixing. The pig iron column is fixed by the end cover 6, and the end cover 6 is also used as a part of the pig iron column to conduct magnetism. The pig iron column is in the shape of a cylinder as a whole. 2 is a ring-shaped winding, which is embedded in the pig iron column. On the pig iron column of the cylindrical pig iron, a slit or slot 3 for blocking the eddy current circle is provided along th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap