Method for producing functional polyester fiber, and polyester products using functional polyester fiber

A technology of polyester fiber and manufacturing method, which is applied to the manufacture of functional polyester fiber and the field of polyester products using functional polyester fiber, can solve the problem of inability to add hydrophobic function, etc., and achieve excellent practicability and durability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] First, as the first process, a predetermined amount of water, 5% owf sodium hydroxide, and 2% owf benzyl alcohol as a penetrating agent were put into a high-pressure liquid flow dyeing machine that added polyester fibers, and carried out at room temperature for 5 Minutes of treatment, followed by heating to 95 ° C for 40 minutes of treatment.

[0099] After the first process is terminated, the inside of the tank is drained and washed with water, and then the second process is performed.

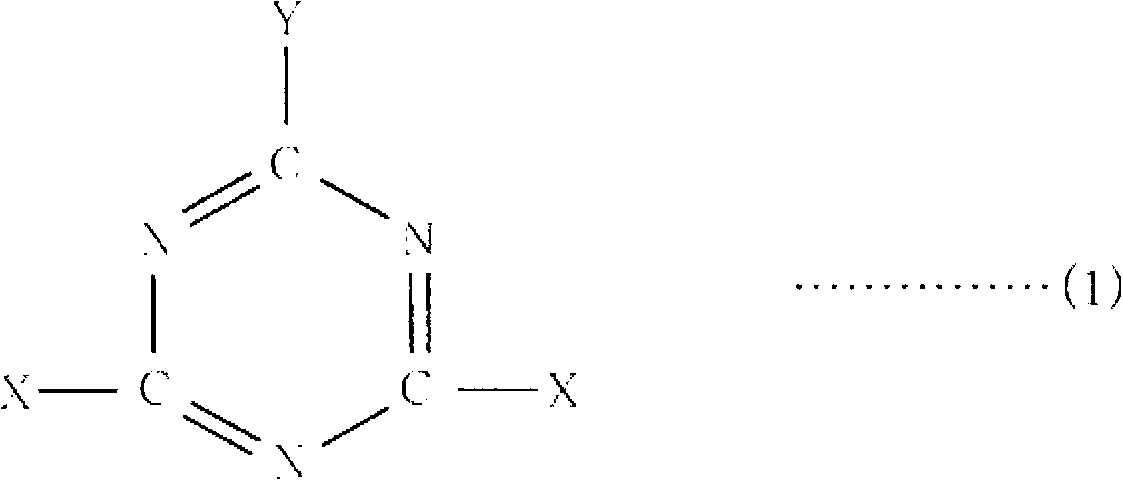

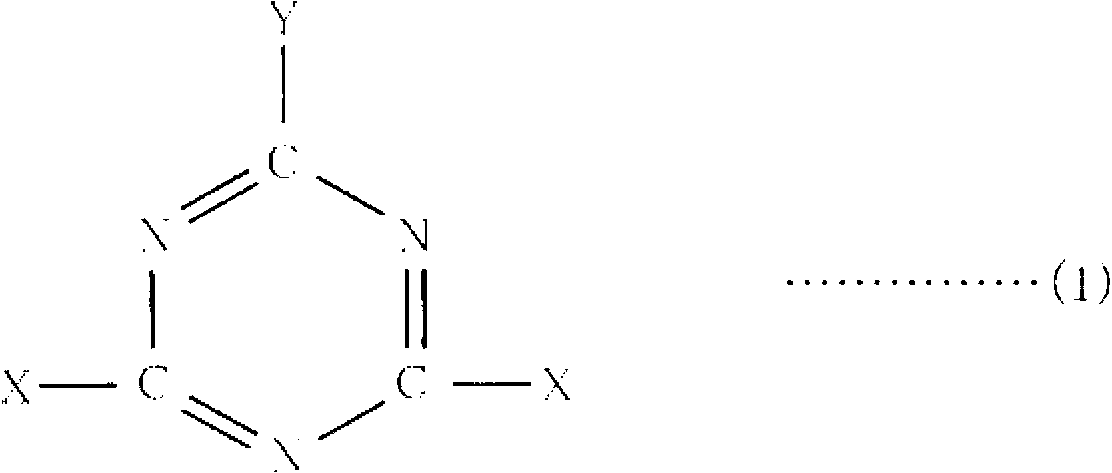

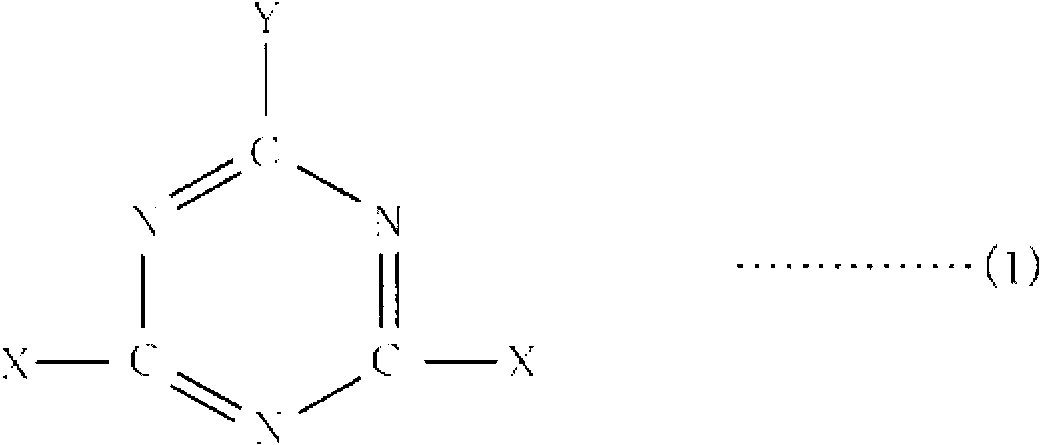

[0100] As the second step, 20% owf of 2,6-dichloro-4-(3-sulfoanilino)-homonium was put into the high-pressure liquid-flow dyeing machine that had been treated in the first step and added polyester fibers. Triazine 10% aqueous solution, Glauber's salt 15g / L, soda 5g / L and baking soda 5g / L, after 5 minutes of treatment at room temperature, heat treatment at a temperature of 1°C per minute between 20°C and 30°C, The first substitution reaction occurs between the reactive group attache

Embodiment 2

[0104] First, as the first process, a predetermined amount of water, 5% owf ethylenediamine, and 2% owf benzyl alcohol as a penetrating agent were put into a high-pressure liquid flow dyeing machine with polyester fibers, and carried out at room temperature for 5 Minutes of treatment, followed by heating to 95 ° C for 40 minutes of treatment.

[0105] After the first process is terminated, the inside of the tank is drained and washed with water, and then the second process is performed.

[0106] As the second step, a 10% aqueous solution of 2,6-dichloro-4-oxo-s-triazine Na salt at 20% owf was put into a high-pressure liquid flow dyeing machine filled with the polyester fiber treated in the first step. , Glauber's salt 15g / L, soda 5g / L, and baking soda 5g / L, after 5 minutes of treatment at room temperature, the temperature was raised at 1°C per minute between 20°C and 30°C, and heat treatment was carried out at the same time, so that the polyester The first substitution rea

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap