Button cell seal ring and button cell

A button battery and sealing ring technology, which is applied in the direction of nickel storage battery, alkaline storage battery, battery pack components, etc., can solve the problems of low battery weight and volume specific capacity, large internal space of button battery, and increased battery manufacturing cost, etc. , to achieve the effect of increasing the internal space, reducing the current density and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

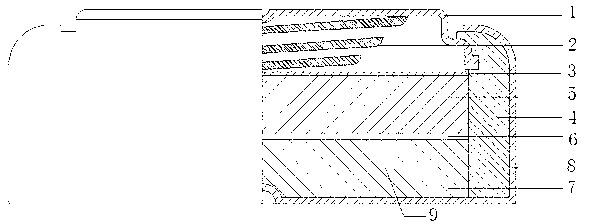

[0010] Embodiments are described in detail with reference to the accompanying drawings. The nickel-hydrogen button battery is composed of a plate set 9, a conical coil spring 2, a negative cover 1, a sealing ring 4 and a positive steel shell 8. The plate set 9 is made of a connecting piece structure or a single piece structure It consists of a nickel positive plate 7, a hydrogen storage alloy negative plate 5 and a separator 6 arranged between the positive plate and the negative plate. The specific combination method is: (1), first combine the flanging negative electrode cover 1 and the seal ring 4 with snap ring together; (2), put the conical coil spring 2 into the combined seal ring 4 in the direction of the negative electrode cover 1 , and then put the punched gasket or burr gasket 3 on the conical coil spring 2 (whether to put the punched gasket or the burr gasket depends on the battery negative base material); (3), the negative plate 5, the diaphragm 6 Cross-fold with the p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap