Highway maintenance construction equipment

A technology for construction equipment and highway maintenance, applied in the direction of roads, roads, road repair, etc., can solve problems affecting the progress of construction, asphalt pollution, serious problems, etc., and achieve the effect of improving service life, ensuring reliability, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

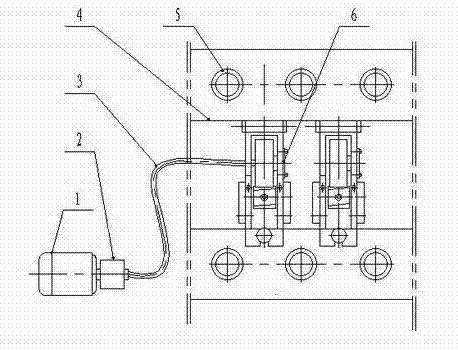

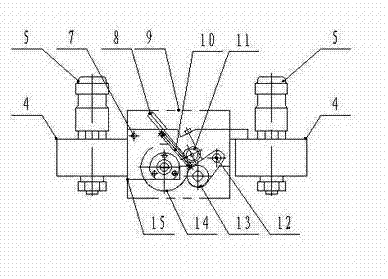

[0009] The embodiment is described in detail in conjunction with the above accompanying drawings. The motor 1 of the power system of the present invention is fixed on the clutch transfer case 2, and one end of the flexible wire shaft 3 is connected with the clutch transfer case, and the other end thereof is connected with the driving shaft on the driving rubber wheel 14. connection, the clutch transfer case has a plurality of coupling holes that can be connected to the steel wire flexible shaft; the asphalt spraying beam 4 is assembled on the front and rear sides of the fiber shearing mechanism 6, and the asphalt spraying control valve is assembled on the asphalt spraying beam through nuts Pressing up and down, one end of the fiber shearing mechanism 6 is hinged with the front side asphalt spraying beam through the connecting pin 7, and the other end is pressed on the rear side asphalt spraying beam through a nut. Described fiber shearing mechanism is by shearing mechanism fixed f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap