Method for manufacturing stable high temperature-resistant hydrogen end group conducting channel on diamond surface

A surface fabrication and conductive channel technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of p-type channel failure, adsorption layer and hydrogen end group decomposition, and large environmental impact, and achieve the realization of normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

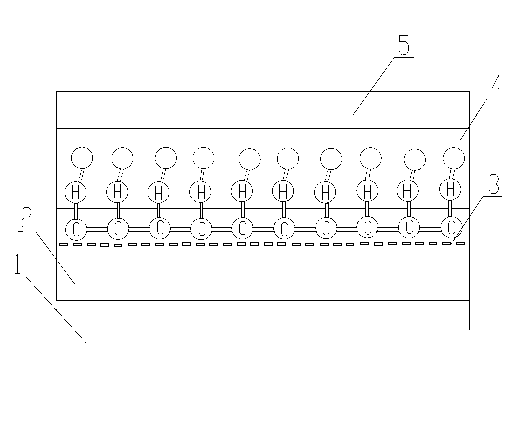

Image

Examples

Embodiment 1

[0025] Example 1: (1) A high-resistance diamond of 300 μm was grown on a molybdenum substrate by microwave plasma chemical vapor deposition;

[0026] (2) Form a p-type conductive channel on the high-resistance diamond material by hydrogen plasma treatment for 30 minutes;

[0027] (3) The hydrogen-terminated diamond obtained after treatment is placed in a chemical vapor deposition equipment and vacuumed to 10 -4 mbar, then into NH 3 and H 2 The mixture of which NH 3 The flow rate is 500mL / min, H 2 The flow rate is 20L / min, the reaction chamber pressure is 100mbar, and the treatment time is 1 hour.

[0028] (4) After taking out the sample, deposit 3nm HfO in the atomic layer deposition equipment at room temperature 2 The dielectric barrier layer prevents the surface of the hydrogen-terminated diamond adsorbed with polar molecules and functional groups from being directly exposed to the environment.

Embodiment 2

[0029] Example 2: (1) A high-resistance diamond of 300 μm was grown on a molybdenum substrate by a direct current arc method;

[0030] (2) Form a p-type conductive channel on the high-resistance diamond material by hydrogen plasma treatment for 30 minutes;

[0031] (3) Soak the hydrogen-terminated diamond obtained after treatment in trimellitic anhydride TMA for 30 min;

[0032] (4) After taking out the sample, deposit 3nm Al in the atomic layer deposition equipment at room temperature 2 o 3 The dielectric barrier layer prevents the surface of the hydrogen-terminated diamond adsorbed with polar molecules and functional groups from being directly exposed to the environment.

[0033] When this hydrogen-terminated diamond is exposed to an atmosphere of polar molecules, it will adsorb the polar molecules and form an electrochemical system. In this system, the electronegativity of the C-H dipole is 1.3eV, and the valence band is higher than The chemical potential of adsorbed polar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap