Supporting steel pipe device of underground added layer of existing building and installing method of supporting steel pipe device

A technology for adding layers underground and supporting steel pipes, which is applied in construction, building maintenance, building construction, etc. It can solve problems such as difficult parking, undesigned underground parking lot, lack of foresight, etc., and achieve light lifting equipment and less insertion of steel pipes The effect of reducing the time and reducing the engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

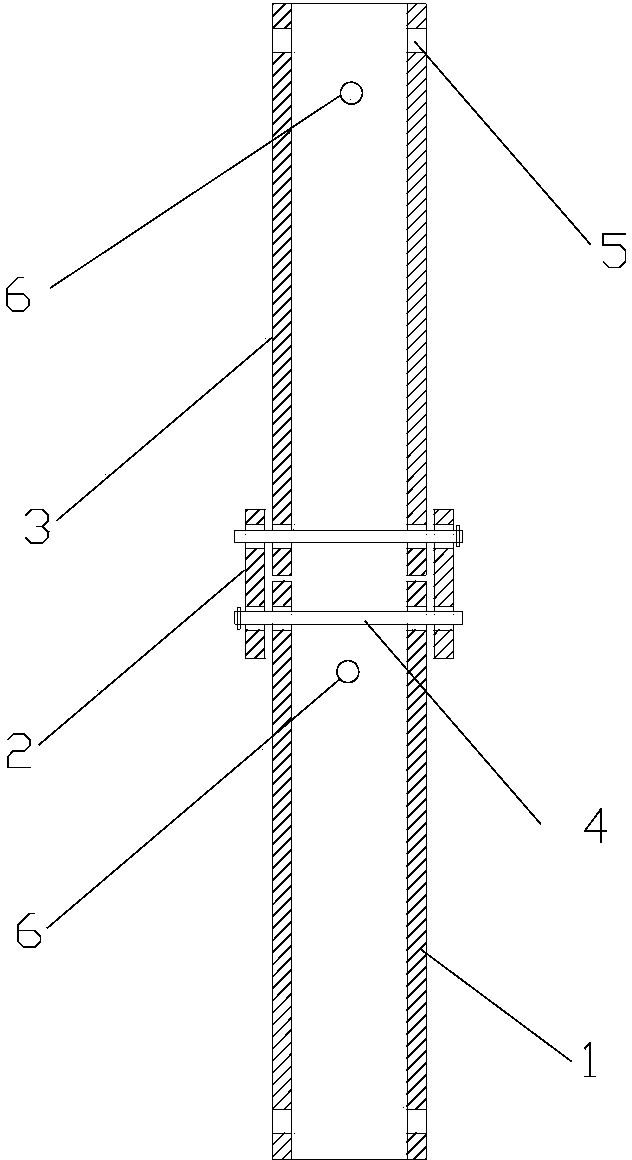

[0032] figure 1 , Figure 3-Figure 7 As shown, the existing supporting steel pipe device for building underground storeys includes at least two sections of steel pipes, and the two adjacent sections of steel pipes (ie, the upper section of steel pipe 3 and the lower section of steel pipe 1 ) are connected by jacket type steel pipe joints 2 and short pins 4 , the inner diameter of the jacket-type steel pipe joint 2 is greater than the outer diameters of two adjacent sections of steel pipes. The upper end of the steel pipe is provided with a first jack 6 that can be inserted into a long bolt outside the length range of the jacket-type steel pipe joint 2; The second insertion hole 5 of the short plug is inserted, and the first plug 6 and the second plug 5 are staggered by 90° on the circular section of the same steel pipe.

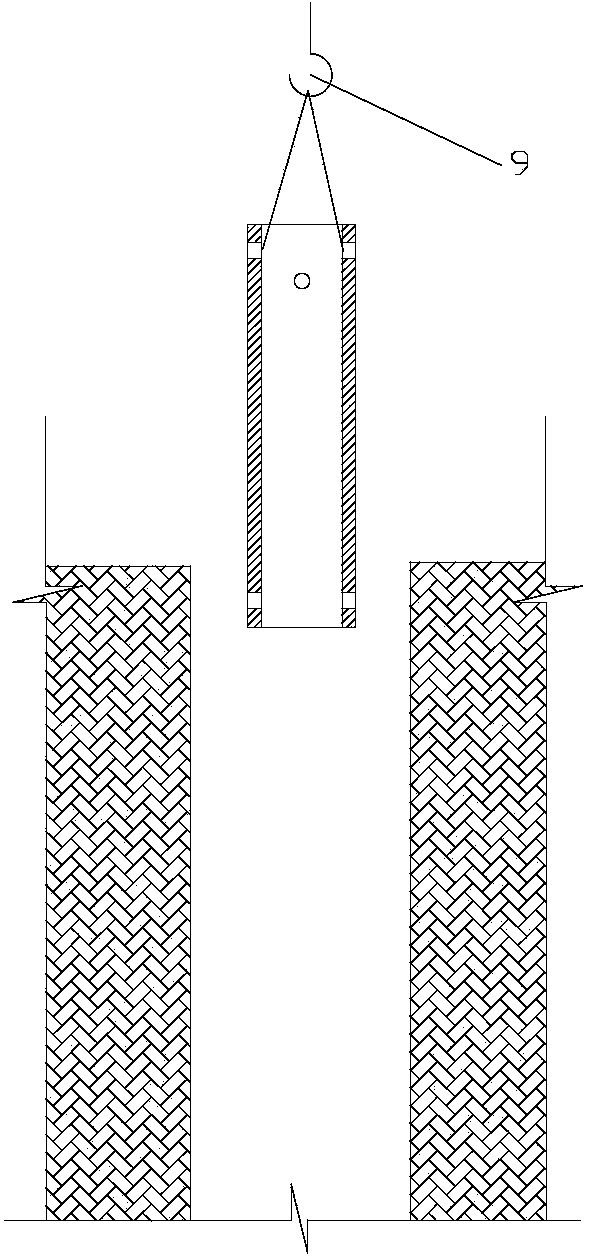

[0033] A method for installing a supporting steel pipe device for adding floors underground in an existing building, comprising:

[0034] (1) Drill holes on

Embodiment 2

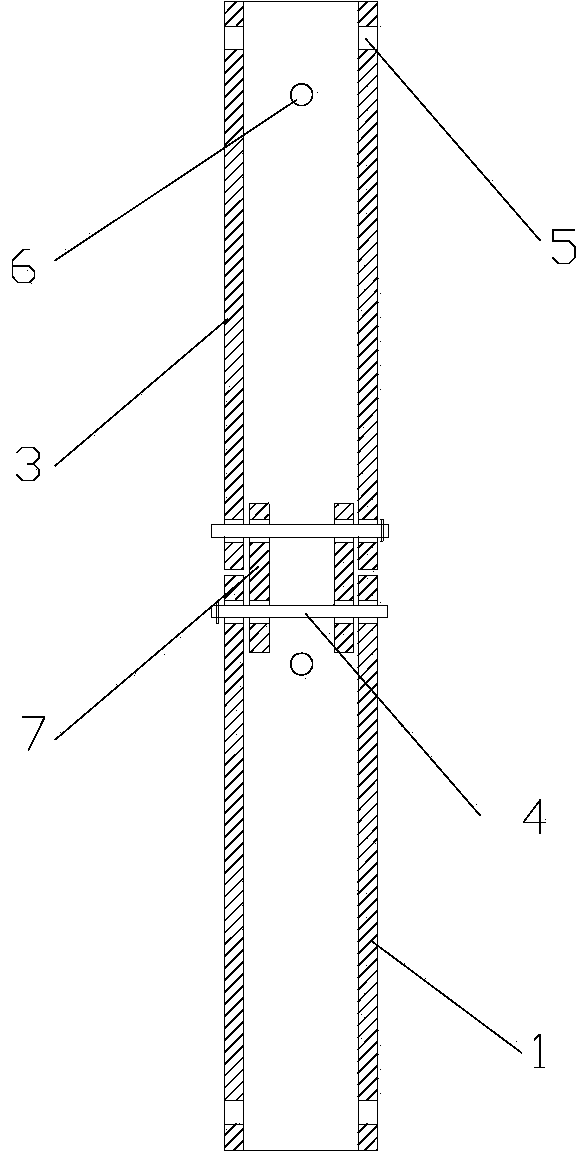

[0044] Such as Figure 2-Figure 5 As shown, the supporting steel pipe device for building underground storeys in existing buildings includes at least two sections of steel pipes, and the two adjacent sections of steel pipes (that is, the upper section of steel pipe 3 and the lower section of steel pipe 1 ) are connected by interpolated steel pipe joints 2 and short pins 4 connection, the outer diameter of the plug-in steel pipe joint 7 is smaller than the inner diameters of two adjacent sections of steel pipes. The upper end of the steel pipe and outside the length range of the interpolated steel pipe joint 7 are provided with a first socket 6 that can be inserted into a long bolt; The second insertion hole 5 of the short plug is inserted, and the first plug 6 and the second plug 5 are staggered by 90° on the circular section of the same steel pipe.

[0045] A method for installing a supporting steel pipe device for adding floors underground in an existing building, comprising:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap