Board cutting device

A cutting device and a technology for wood boards, which are applied to sawing equipment, wood processing appliances, circular saws, etc., can solve the problems of low efficiency and inconvenience in cutting wood boards, and achieve the effect of convenient and high efficiency in cutting wood boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

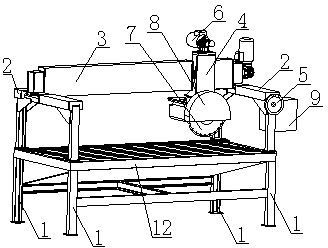

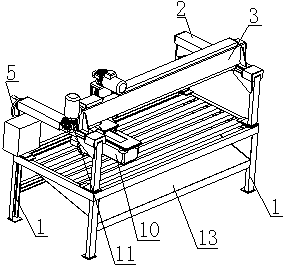

[0016] Such as Figure 1 to Figure 2 As shown, a kind of plank cutting device comprises a support bar 2 and several legs 1 supporting the support bar 2, a carrier 12 is arranged between the legs 1, a slideway 3 is arranged between the support bars 2, and a slideway 3 is arranged on the slideway 3 There is a transverse slider 4, one end of the transverse slider 4 is provided with a cutting wheel 7, the other end of the transverse slider 4 is provided with a driving motor 6, the driving motor 6 is electrically connected to the cutting wheel 7, and the cutting wheel 7 is arranged on the carrier Above 12, the foot 1 is provided with a hand wheel 5 for c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap