Semi-trailer coupling

A technology of semi-trailer connection and semi-trailer, which is applied in tractor-trailer combination, motor vehicle, transportation and packaging, and can solve problems such as tilting, jamming, and large handle 132

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

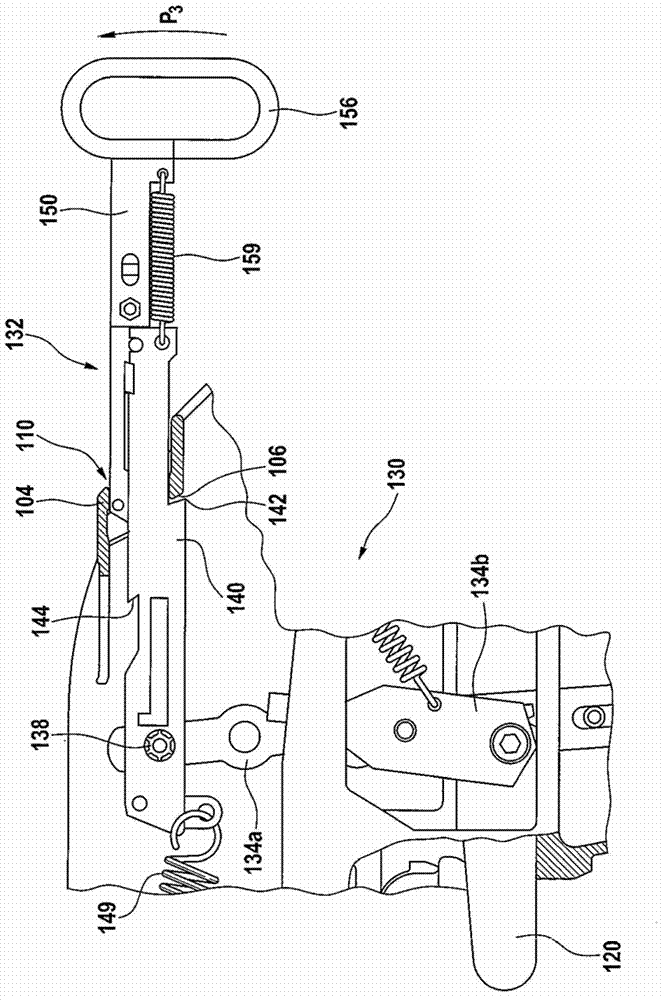

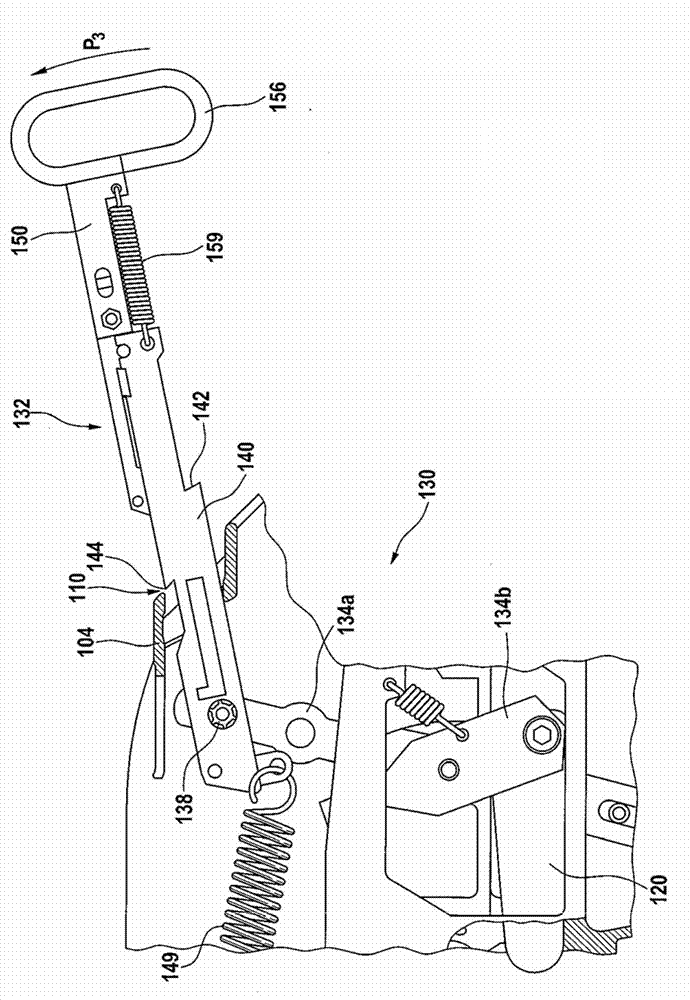

[0050] image 3 and Figure 4 A bottom view of the trailer connection plate 2 and part of the side wall 4 of the trailer connector 1 is shown. The space below the semi-trailer connecting plate 2 bounded by the side wall 4 forms an interior space 5 . The space outside the side wall 4 is the external space 9 .

[0051] The side wall 4 forms, with the opening 10 , a guide 80 for the actuating mechanism 30 of the pull handle 32 , wherein the pull handle 32 has the pull rod 40 and the safety rod 50 . The guide space 82 is defined by the boundaries of the opening 10 .

[0052] The safety bar 50 is arranged longitudinally movable relative to the tie rod 40 . For this purpose, a guide hole 46 is provided in the tie rod 40 , in which the guide 52 of the safety rod 50 is guided. The length of the guide hole 46 defines the extraction path of the safety bar 50 and at its two ends 47a, 47b defines the rest position and the extraction position of the safety bar 50 .

[0053] The width BZ

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap