Method for preparing high-performance molecular sieve membrane through ion exchange at melting state

An ion exchange, molecular sieve membrane technology, applied in separation methods, molecular sieve and alkali exchange of phosphate, chemical instruments and methods, etc., can solve the problems of slow ion exchange and improve the selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Li-SAPO-34 molecular sieve membrane was prepared by immersing in 1wt% lithium nitrate acetone solution and performing ion exchange in air at 300°C for 8 hours

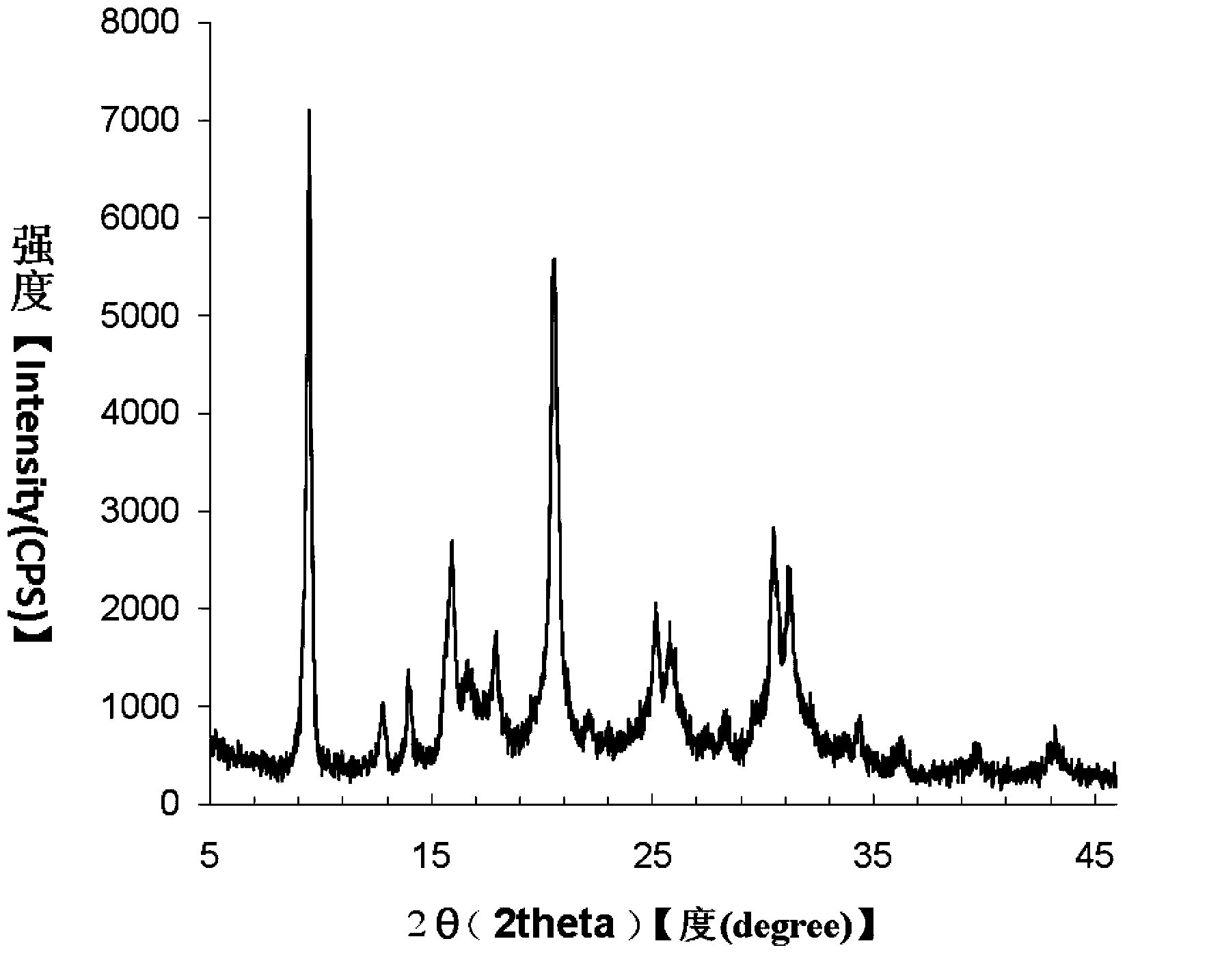

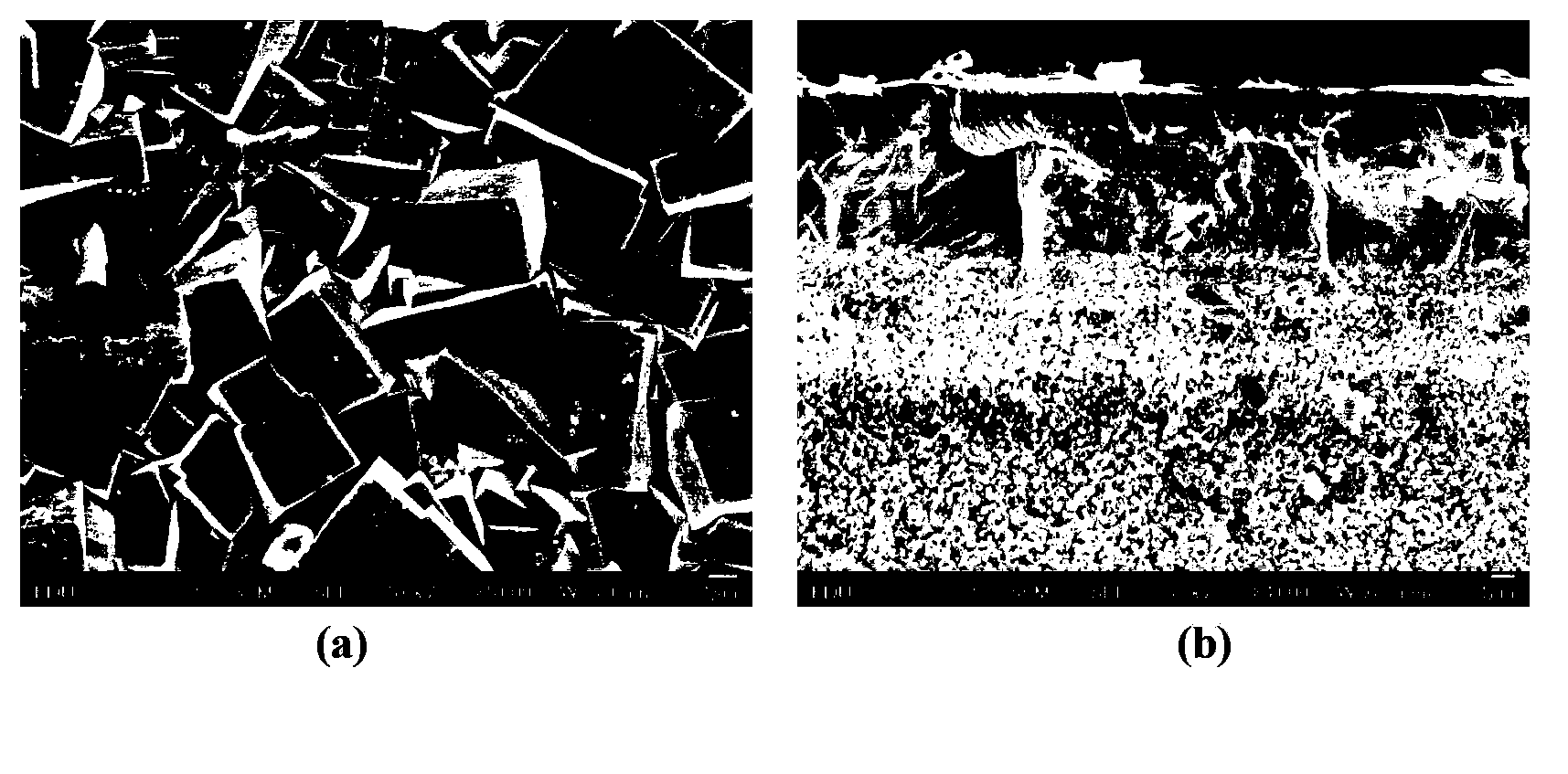

[0048] Step 1: Add 2.46 g of deionized water to 31.13 g of tetraethylammonium hydroxide solution (TEAOH, 35 wt%), then weigh 7.56 g of aluminum isopropoxide and add it to the aforementioned solution, and stir at room temperature for 2-3 hours; then Add dropwise 1.665g silica sol (40wt%), stir 1 hour; Finally slowly add dropwise 8.53g phosphoric acid solution (H 3 PO 4 , 85wt%), stirred overnight. Microwave heating was used for crystallization at 180°C for 7 hours. After the product was taken out, it was centrifuged, washed with deionized water, and dried to obtain SAPO-34 molecular sieve seed crystals. SEM images of SAPO-34 molecular sieve seed crystals, such as figure 1 As shown, the seed crystal is a flaky crystal of 300×300×100 nm. The XRD pattern of SAPO-34 molecular sieve seed crystal, such as

Embodiment 2

[0063] Example 2 Soak in 1wt% potassium acetate aqueous solution, and prepare K-SAPO-34 molecular sieve membrane by ion exchange in 300°C air for 8 hours

[0064] The difference from Example 1 is that in Step 5, the molecular sieve membrane tube obtained in Step 4 was soaked in 1 wt% potassium acetate aqueous solution for 3 minutes, and dried at room temperature. All the other steps are the same as in Example 1. The seed crystals used are flaky crystals with a size of 300×300×100 nm. Figure 5 It is the SEM picture of the molecular sieve membrane after ion exchange, such as Figure 5 As shown, it can be seen that ion exchange has no significant effect on the morphology of the membrane.

[0065] CO 2 / CH 4 The gas separation test method is the same as in Example 1, and the test results are shown in Table 3. Molecular sieve membrane CO after ion exchange 2 / CH 4 The separation selectivity of the mixed gas is 60, which is respectively increased by 33% compared with that b

Embodiment 3

[0070] Example 3 Soak in 1wt% sodium nitrate aqueous solution, ion exchange in air at 310°C for 8 hours to prepare Na-SAPO-34 molecular sieve membrane

[0071] The difference from Example 1 is that in step 5, the molecular sieve membrane tube obtained in step 4 was soaked in 1 wt% sodium nitrate aqueous solution for 3 minutes, and dried at room temperature. The roasting temperature in step 4 is 310 ℃. All the other steps are the same as in Example 1. The seed crystals used are flaky crystals with a size of 300×300×100 nm.

[0072] CO 2 / CH 4 The gas separation test method is the same as in Example 1, and the test results are shown in Table 4. Molecular sieve membrane CO after ion exchange 2 / CH 4 The separation selectivity of the mixed gas is 63, which is respectively increased by 29% compared with that before the exchange.

[0073] Table 4 CO of Example 3 2 / CH 4 Gas Separation Test Results

[0074]

[0075] Note: The pressure difference between the feed side

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap