Process for recovering wastewater in production of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and derivatives thereof

A technology for producing wastewater and phosphaphenanthrene, which is applied in the chemical industry, can solve the problems of no treatment method for wastewater, high concentration of harmful substances and high salt content, and achieve the effects of resource recycling, high adsorption efficiency and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

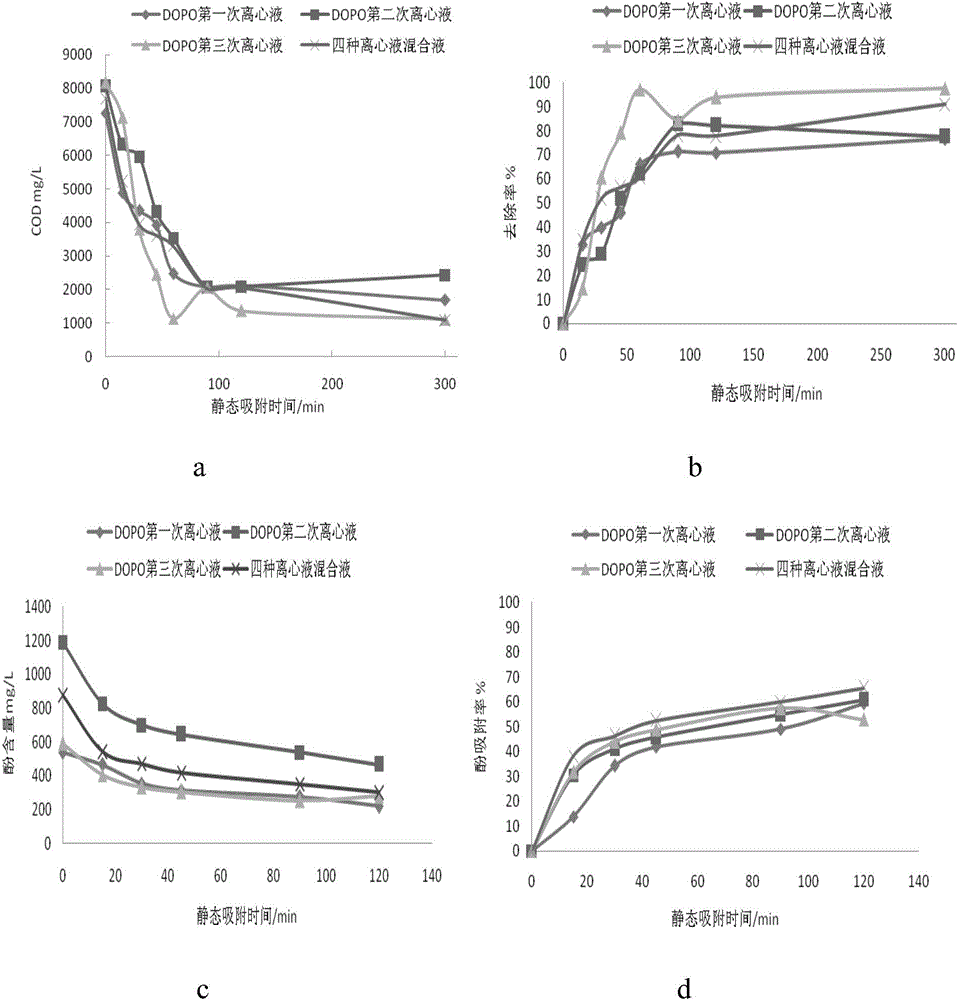

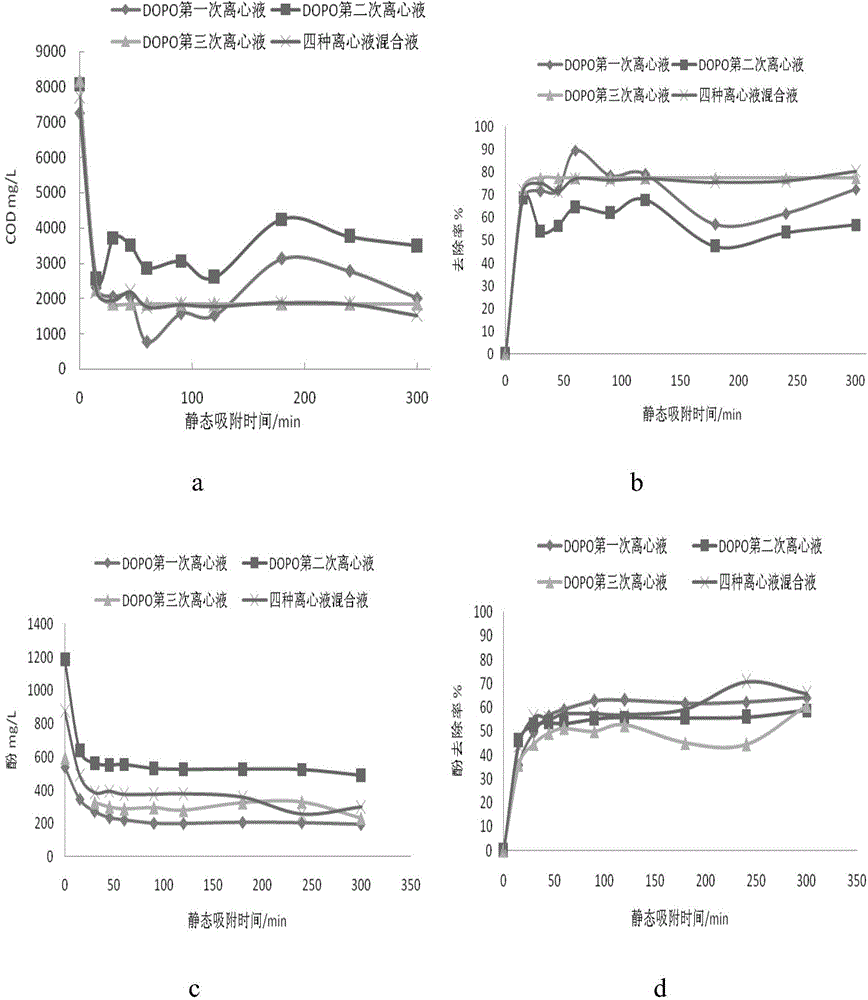

[0044] Embodiment 1. Wastewater treatment process selection and resin adsorption experiment

[0045] 1. Selection of wastewater treatment process

[0046] According to the water quality characteristics of the wastewater and combined with the analysis of the production process, the wastewater is difficult to be treated by ordinary "physicochemical + biochemical" methods, and the organic matter contained in the wastewater is relatively simple, which has a certain recovery value. For this reason, the inventor adopts resin adsorption method to treat wastewater. Polymer adsorption resin has the advantages of large specific surface area, high adsorption efficiency, and stable performance. It is often used to treat high-concentration and refractory organic chemical wastewater, especially for phenol and amine , nitro substances, organic acids and other wastewater, not only can achieve effective treatment of organic pollution, but also can achieve resource recycling.

[0047] The main fa

Embodiment 2

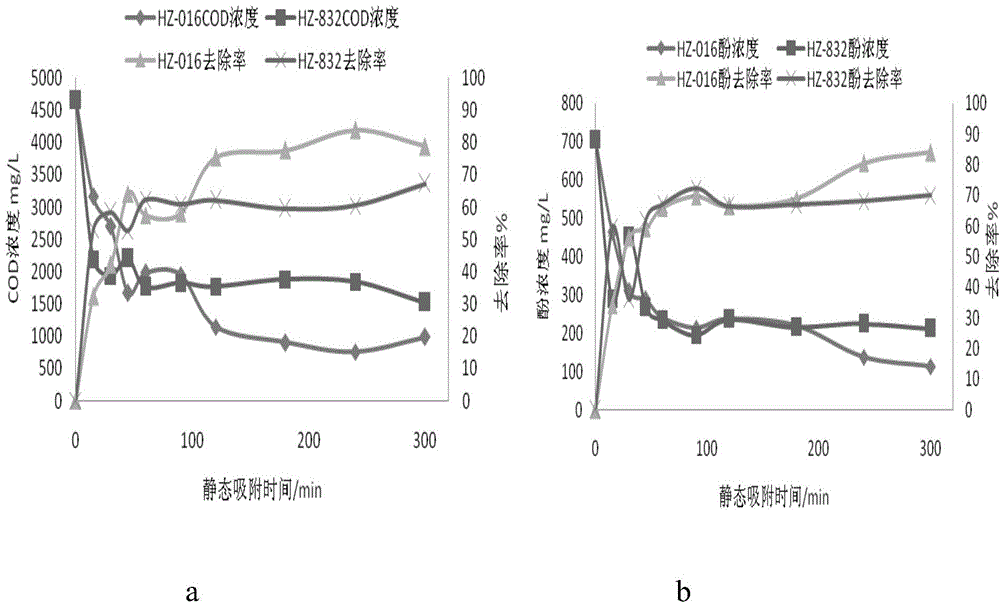

[0073] Example 2. Continuous adsorption-desorption operation experiment of HZ-016 resin with 4% NaOH solution as desorbent

[0074] 1. Experimental conditions

[0075] 1.1 Dynamic Adsorption

[0076] DOPO mixed solution (mixed according to the ratio of 1.1:1:2.2) at room temperature and the original pH (pH=2.50 or so) conditions, at a flow rate of 4BV / h from top to bottom through a 50ml (wet volume) HZ-016 adsorption Resin glass adsorption column (inner diameter 20mm, length 300mm). Under these operating conditions, the HZ-016 resin bed adsorbs 24BV mixed liquid.

[0077] 1.2 Dynamic desorption

[0078] With 4% NaOH solution as the desorbing agent, under the condition of T=45°C, pass through the glass adsorption column equipped with 1BV (1BV=50ml wet volume) HL-1 type dynamic adsorption saturated resin from top to bottom at a flow rate of 0.2BV / h (inner diameter 20mm, length 300mm). Under this operating condition, the amount of desorbent is 2BV.

[0079] 2. Continuous o

Embodiment 3

[0096] Example 3. Research on advanced treatment technology of effluent treated by resin adsorption

[0097] The effluent after resin adsorption still contains certain pollutants, especially the concentration of volatile phenols exceeds the standard, so it needs to be further treated to meet the relevant requirements of the discharge standard. Therefore, according to the water quality characteristics of the wastewater, Fenton oxidation and NaClO oxidation were selected.

[0098] 1. Fenton oxidation experiment

[0099] Experimental method: Take 100mL resin to absorb water, add a certain amount of H 2 o 2 and Fe 2+, After stirring for 30 minutes on a constant temperature magnetic stirrer, the pH was adjusted to 8 with lye to terminate the experiment, and the concentrations of COD and phenol were measured. Experimentally investigated Fe 2+ and H 2 o 2 The effect of dosage on treatment effect. Experimental results such as Figure 20 shown.

[0100] Depend on Figure 20 a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap