LED panel lamp structure with novel lighting manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

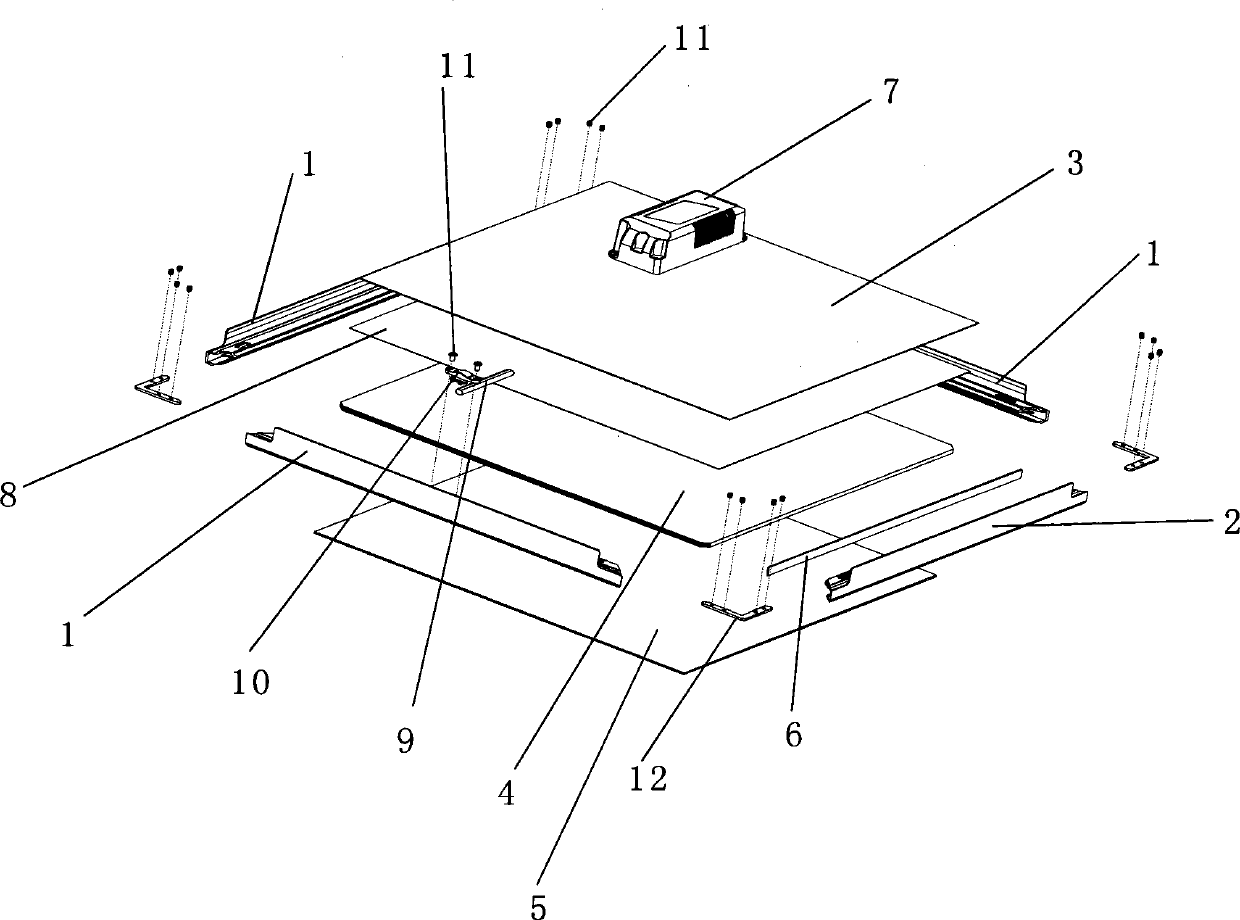

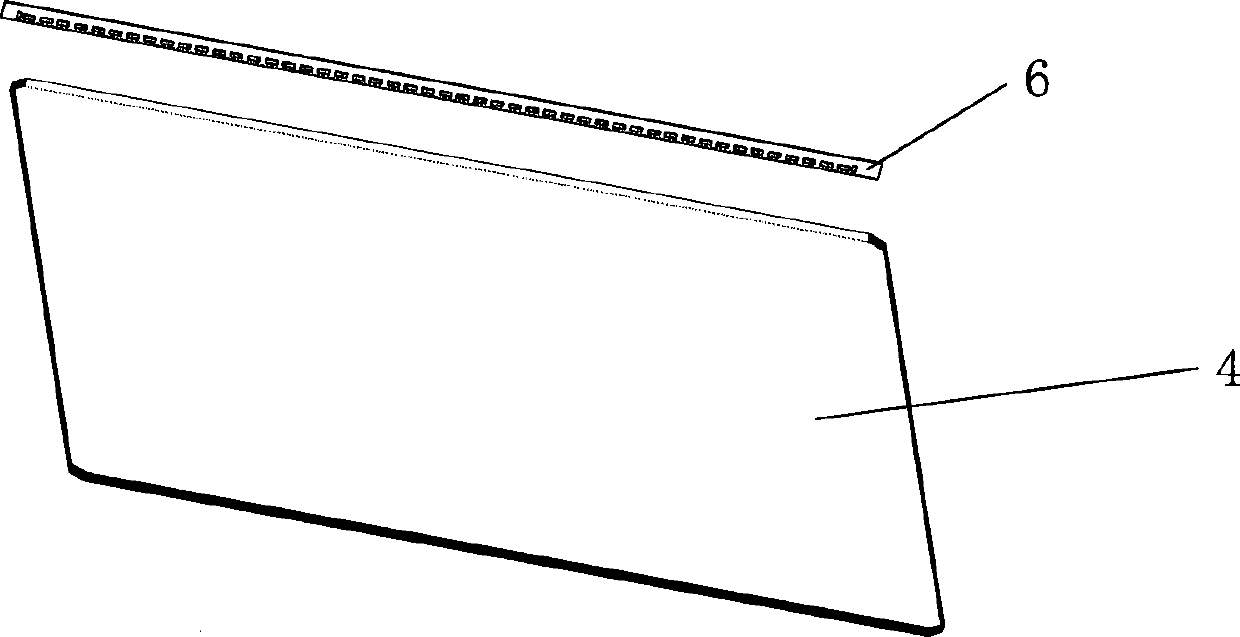

[0021] Such as figure 1 , 2 As shown, the present invention provides a LED panel light structure with a new light output mode, the panel light includes a frame 1, a back plate 3, a light guide plate 4, a diffusion plate 5, a light source plate 6 and a driver 7, and the light source plate 6. Paste on one of the frame I2 with heat-conducting double-sided adhesive tape as the light-incoming side; the surface of the light guide plate 4 is pasted with a layer of reflective film 8, so that the light returns to the light guide plate 4 and is evenly distributed on the light guide plate 4 to emit light from the front , the diffuser plate 5, the light guide plate 4 and the back plate 3 are integrated and clamped on the frame I2 of the light source plate 6 and the other three frames 1; the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap