Labor-saving safety hammer

A safety hammer, labor-saving technology used in hammers. It can solve the problems of heavy weight, safety, slip and hurt the human body, etc., and achieve the effect of small size, light weight, easy to carry and store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

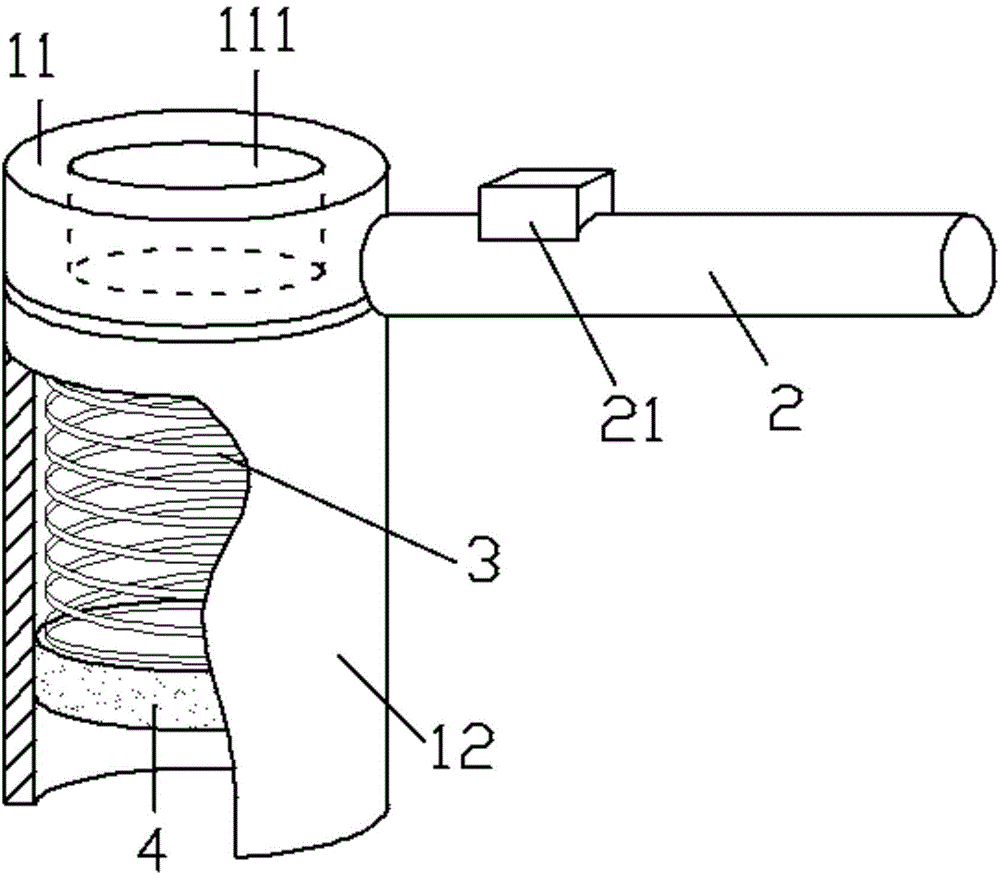

[0011] exist figure 1 In the illustrated embodiment, the labor-saving safety hammer includes a hammer head and a handle 2; the hammer head includes a top seat 11 and a sleeve 12 fixed on the top seat 11; material, the outer wall of the sleeve 12 is covered with a heat insulating layer; and a heating coil (not shown in the figure) is arranged inside the cylinder wall; the axis of the heating coil coincides with the axis of the sleeve 12; The heating coil is electrically connected to the neutral wire and live wire of the alternating power supply 111 inside the top base 11; the alternating power supply 111 is electrically connected to the control switch 21 provided on the handle 2; The inner axis of the sleeve 12 is provided with a power spring 3 made of a memory alloy and one end is fixedly connected to a base, and the base and the top seat 11 are connected by threads (the base is blocked in the figure , not marked); the other end of the power spring 3 is fixed with a hammer 4; th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap