Hydrophobic and spectrum selective glass for solar cell and manufacturing method of glass

A technology for solar cells and spectrum selection, applied in the field of glass for solar cells and its production, can solve the problems of corroding electrodes, affecting the performance and service life of components, and yellowing, so as to improve the conversion output power, realize the anti-reflection effect, maintain the Cleaning and drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

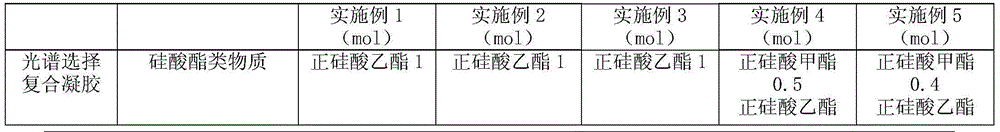

Examples

Embodiment 1

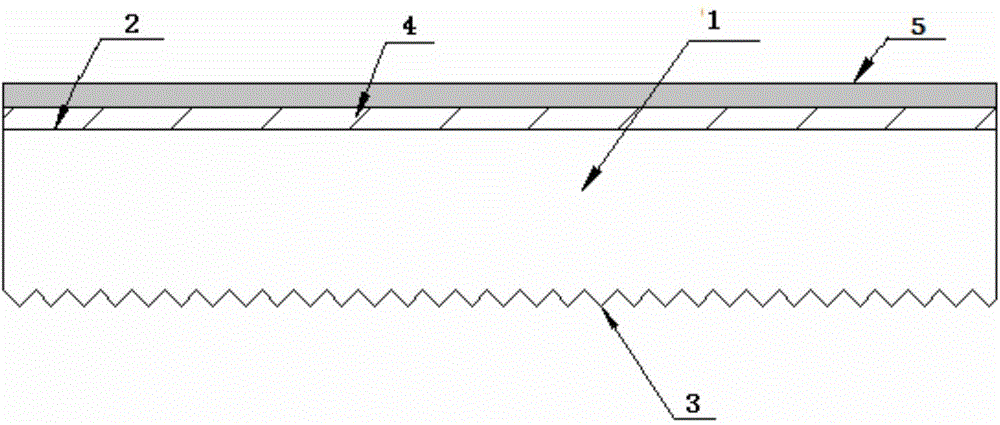

[0053] Such as figure 2 As shown, a solar cell glass with hydrophobic effect and spectral selectivity, wherein:

[0054] The low-iron ultra-clear patterned glass substrate 1 has a thickness of 3.20mm and a transmittance of 91.40%;

[0055] The spectrally selective film layer 4 is obtained from the ingredients in Example 1, the porosity of the film layer is less than 10%, and the film layer refractive index n 2 =1.90, film thickness d 2 =75nm;

[0056] Hydrophobic film layer 5 is obtained by the composition in embodiment 1, and particle diameter is about 15~40nm, and film layer porosity is about less than 10%, and film layer refractive index n 1 =1.50, film thickness d 1 = 95nm.

[0057] In the production method of this embodiment, the temperature in step 3) is 400°C; the temperature in step 5) is 200°C.

[0058] The glass for solar cell that is made by the above-mentioned steps, the surface water contact angle of its hydrophobic film layer 5 is 118 ° (being 32 ° before coa

Embodiment 2

[0060] A solar cell glass with hydrophobic effect and spectral selectivity, its structure is also as figure 2 shown, where:

[0061] The low-iron ultra-clear patterned glass substrate 1 has a thickness of 3.24mm and a transmittance of 91.52%;

[0062] Spectrum selective film layer 4 is made up of the composition in embodiment 2, and film layer porosity is less than 10%, and film layer refractive index n 2 =1.81, film thickness d 2 =75nm;

[0063] Hydrophobic film layer 5 is made up of the composition in embodiment 2, and particle diameter is about 15~40nm, and film layer porosity is about less than 10%, and film layer refractive index n 1 =1.45, film thickness d 1 = 95nm.

[0064] The manufacturing method is the same as that of Example 1, wherein the temperature in step 3) is 410°C; the temperature in step 5) is 210°C.

[0065] The solar cell glass obtained through the above steps has a surface water contact angle of 113° (32° before the coating), and a spectral transmittanc

Embodiment 3

[0067] Such as figure 2 As shown, a solar cell glass with hydrophobic effect and spectral selectivity, wherein:

[0068] The low-iron ultra-clear patterned glass substrate 1 has a thickness of 3.22mm and a transmittance of 91.50%;

[0069] The spectrally selective film layer 4 is obtained from the ingredients in Example 3, the porosity of the film layer is less than 10%, and the film layer refractive index n 2 =1.85, film thickness d 2 =75nm;

[0070] Hydrophobic film layer 5 is obtained by the composition in embodiment 3, and particle diameter is about 15~40nm, and film layer porosity is about less than 10%, and film layer refractive index n 1 =1.48, film thickness d 1 = 95nm.

[0071] Its manufacturing method is the same as that of Example 1, wherein the temperature of step 3) is 420°C; the temperature of step 5) is 230°C.

[0072] The solar cell glass made by the above steps, the surface water contact angle of its hydrophobic film layer 5 is 116 ° (32 ° before coating),

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap