Pumping unit speed reducer shaft head sealing structure

A machine reducer and sealing structure technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor sealing performance, short service life, wear, etc., achieve reliable sealing performance, improve sealing performance, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] The present invention will be described below with reference to the drawings.

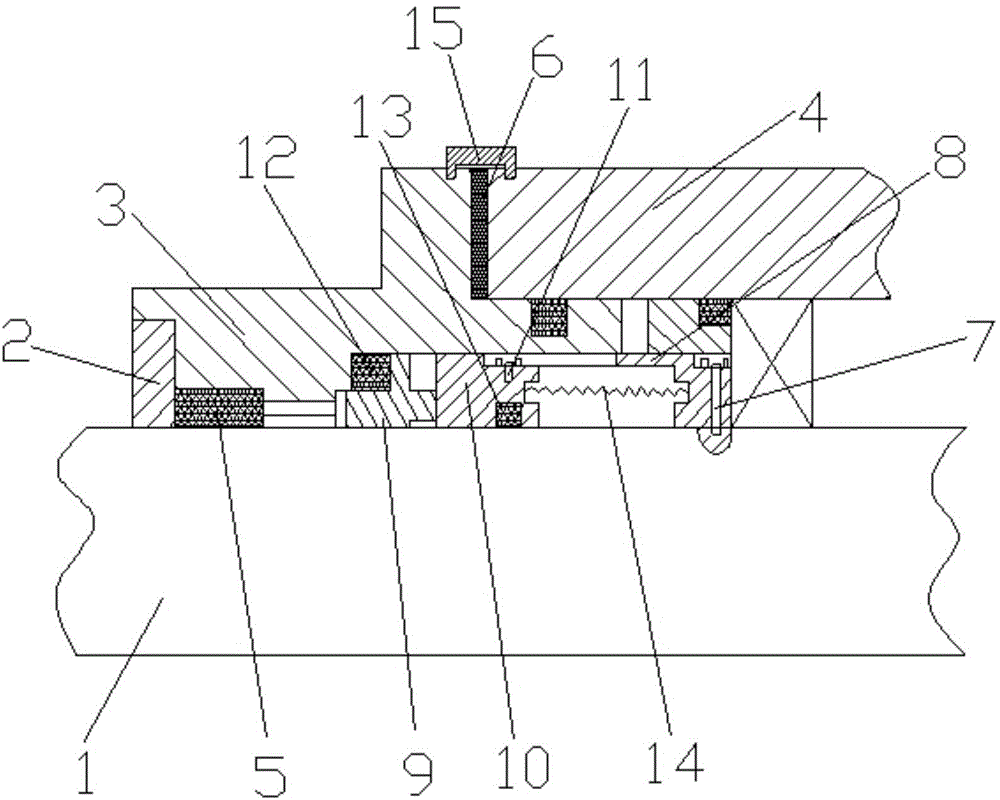

[0011] Attached figure 1 The shaft head sealing structure of the reducer of the pumping unit according to the present invention includes a shaft head 1, a gland 2, a bearing end cover 3, and a box body 4. The gland 2 and the bearing end cover 3 are directly provided with a rectangular shape A rubber ring 5, an asbestos gasket 6 is provided between the bearing end cover 3 and the box body 4, and an asbestos gasket 6 is provided between the bearing end cover 3 and the box body 4, and a sealing cover 15 is also provided; the shaft A transmission sleeve 8 is installed on the head 1 through a fixed pin 7; a static ring 9 is arranged inside the bearing end cover 3; a moving ring 10 is connected to the transmission sleeve 8; a pin 11 is installed on the moving ring 10; The stationary ring 9 and the moving ring 10 are respectively provided with a stationary ring O-shaped rubber ring 12 and a moving ring

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap